Premium Industrial Solutions

Advanced heat-resistant materials and steel products for demanding industrial applications

Gotrays: Leading Supplier of Refractory Solutions

Powering critical industries through advanced refractory materials and expertise.

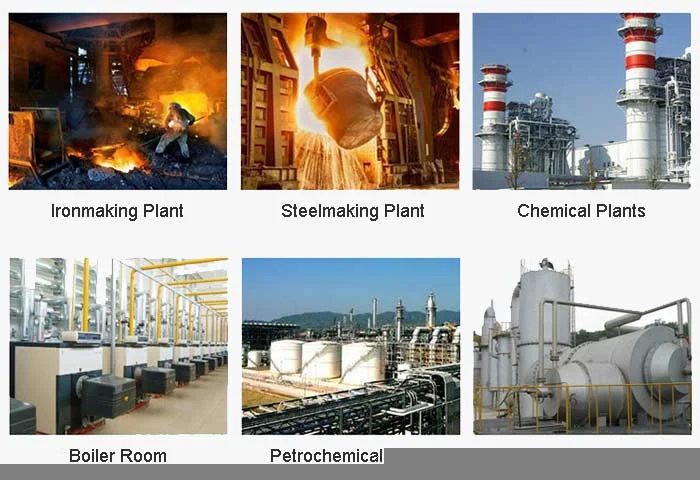

Industry Applications Overview

Refractory materials serve diverse demanding industrial applications by providing essential thermal insulation, corrosion resistance, and structural integrity in extreme high-temperature environments.

Steel Manufacturing

High-performance refractory linings for blast furnaces, ladles, and converters withstand extreme temperatures and chemical corrosion.

Learn more →

Non-Ferrous Metals

Specialized refractories for aluminum, copper, and zinc processing with exceptional thermal shock resistance.

Learn more →

Cement Production

Durable refractory solutions for rotary kilns and preheaters that endure abrasive conditions and thermal cycling.

Learn more →

Glass Manufacturing

High-purity refractories for glass melting furnaces that prevent contamination and maintain product quality.

Learn more →

Petrochemical

Refractory materials for reformers, crackers, and reactors that handle aggressive chemical environments.

Learn more →

Power Generation

Insulating refractories for boilers, incinerators, and thermal power plants that optimize energy efficiency.

Learn more →Iron & Steel: Withstanding Extreme Heat

Discover how specialized materials maintain structural integrity in blast furnaces, converters, ladles, and other high-temperature industrial equipment.

Critical Role in High-Temperature Applications

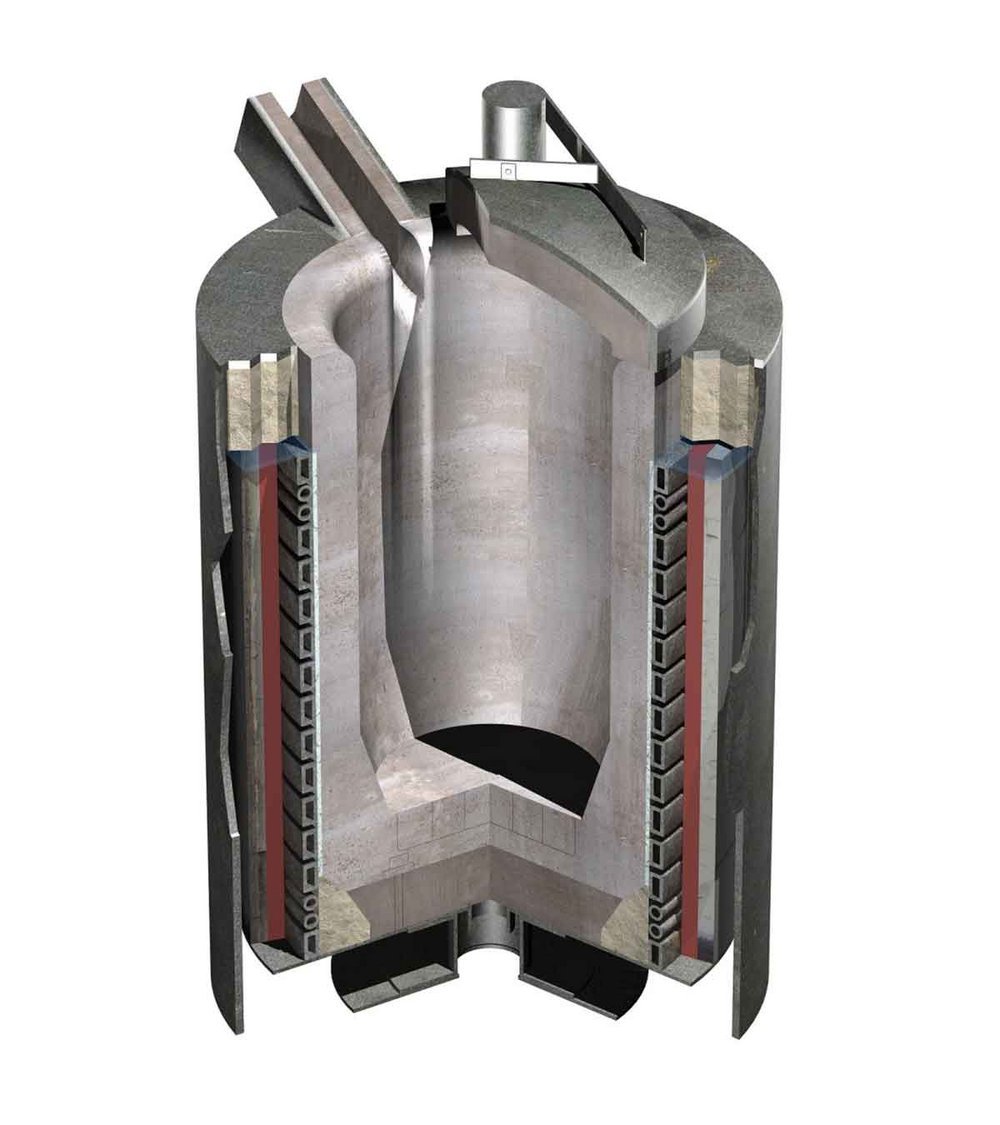

In the demanding environment of steel production, specialized refractory materials and linings are essential for maintaining structural integrity under extreme thermal conditions.

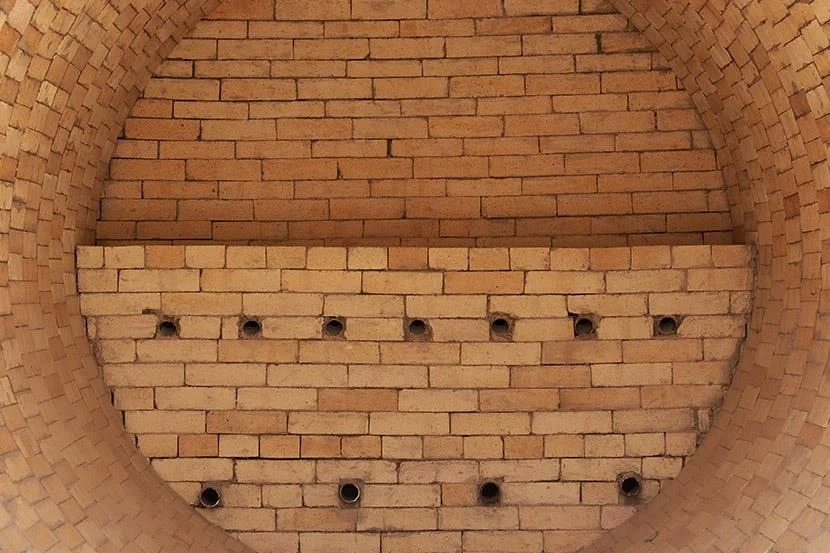

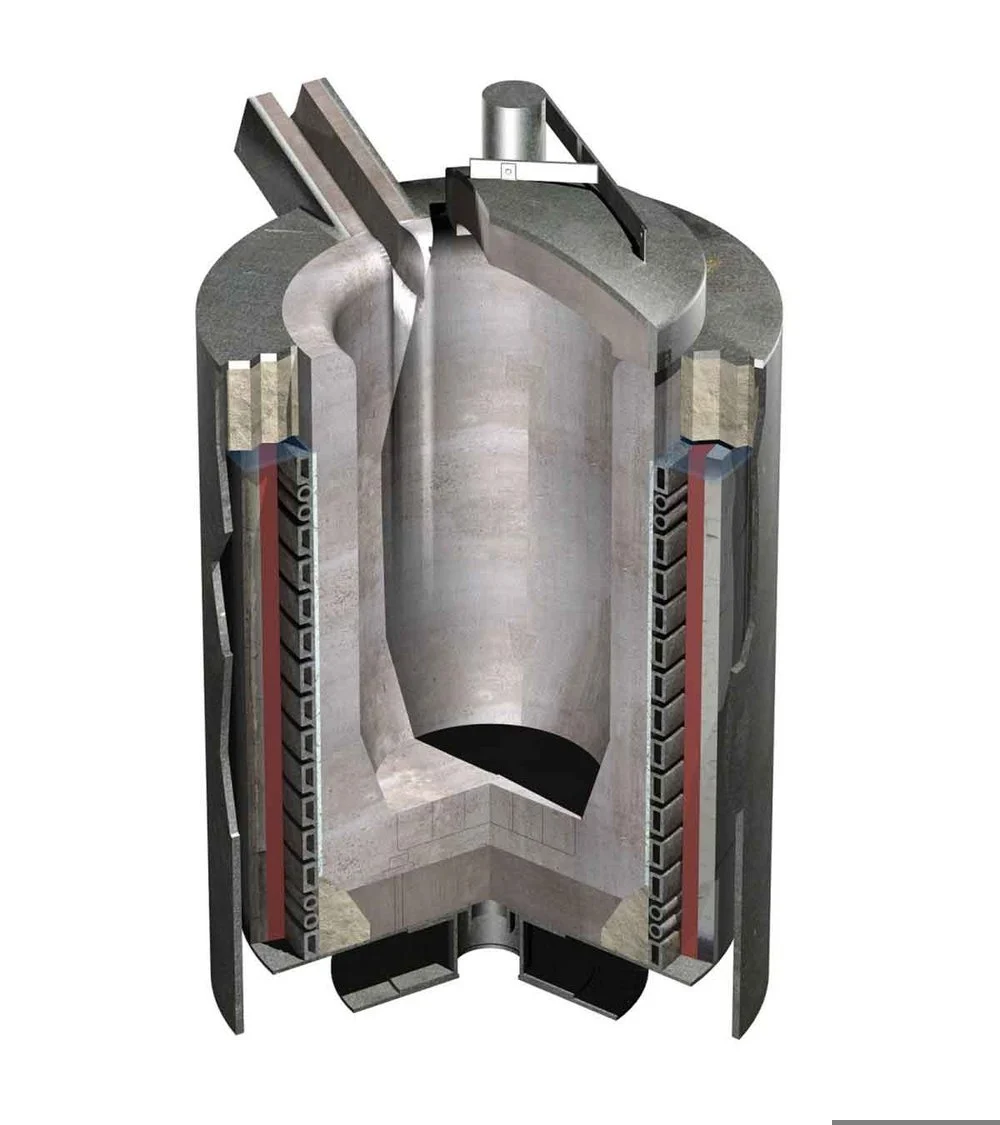

Blast Furnace Linings

Specialized refractory materials withstand temperatures exceeding 2000°C while containing molten iron.

Converter Protection

Heat-resistant linings protect steel converters during the oxygen blowing process and chemical reactions.

Ladle Integrity

Refractory linings ensure ladles maintain structural integrity while transporting molten steel at extreme temperatures.

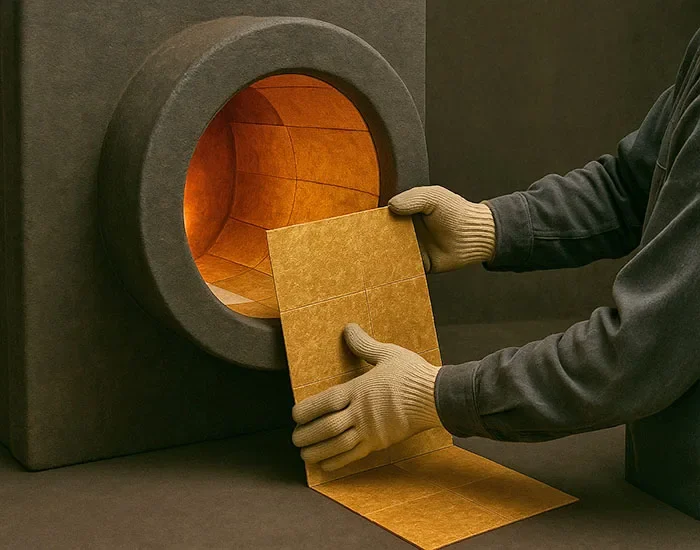

Thermal Insulation

Advanced ceramic fiber blankets provide superior insulation, reducing heat loss and improving energy efficiency in steel production.

Refractory Solutions

Specialized refractory cements and mortars withstand extreme thermal cycling and chemical corrosion in industrial furnaces.

Structural Integrity

Engineered refractory bricks maintain structural stability under intense heat and mechanical stress in steelmaking equipment.

Gotrays - Engineering Excellence in Extreme Conditions

Precision Foundry Solutions

Gotrays delivers exceptional refractory lining technology for molding, casting, and heat treatment processes, ensuring superior quality and durability in metal casting operations.

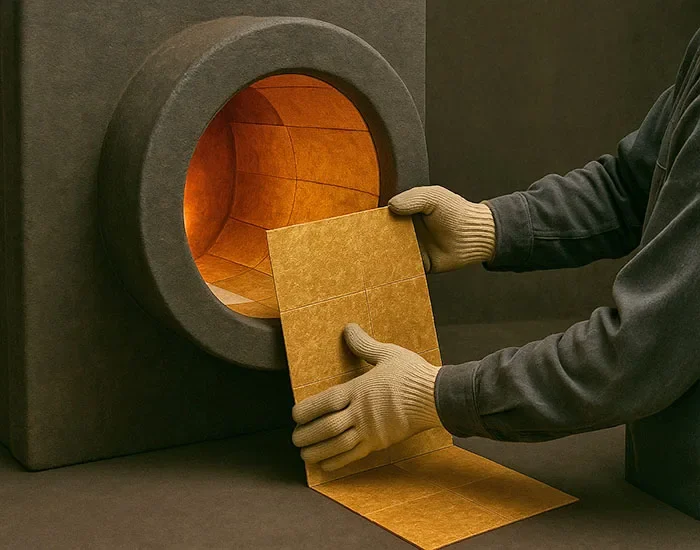

Advanced Refractory Linings

Our specialized refractory materials provide exceptional thermal resistance and structural integrity, maintaining precise temperature control throughout the casting process.

Gotrays' innovative lining solutions minimize heat loss, reduce energy consumption, and extend equipment lifespan while ensuring consistent metal quality.

Thermal Efficiency

Optimized refractory materials maintain consistent temperatures, reducing energy costs and improving process efficiency.

Quality Assurance

Rigorous quality control ensures every refractory lining meets the highest standards for durability and performance.

Custom Solutions

Tailored refractory systems designed for specific foundry applications and operating conditions.

Advanced Refractory Solutions for Non-Ferrous Metallurgy

Protecting furnaces and holding vessels in aluminum, copper, zinc, and nickel smelting and refining operations to ensure purity control and energy efficiency.

Critical Protection for Smelting Operations

Our refractory materials are engineered to withstand extreme temperatures and corrosive environments in non-ferrous metal production, ensuring operational integrity and process efficiency.

Purity Control

Prevent contamination and maintain metal quality throughout the smelting process

Energy Efficiency

Optimize thermal performance and reduce energy consumption in refining operations

Extended Lifespan

Increase service life of furnaces and vessels with superior refractory materials

Thermal Management

Advanced refractory systems designed for optimal heat retention and distribution in high-temperature applications

Corrosion Resistance

Specialized materials that withstand aggressive chemical environments in metal refining processes

Process Integrity

Maintain strict purity standards and prevent contamination in sensitive metallurgical operations

Trusted by leading non-ferrous metal producers worldwide

Advanced Cement & Lime Applications

Superior durability in rotary kilns and preprocessors against chemical corrosion and thermal cycling

Rotary Kiln Performance

Our specialized cement and lime formulations are engineered to withstand extreme conditions in rotary kilns, maintaining structural integrity under intense thermal cycling and chemical exposure.

Thermal Cycling Resistance

Maintains performance through repeated heating and cooling cycles

Chemical Corrosion Protection

Resists degradation from aggressive industrial chemicals

Preprocessor Applications

Designed for preprocessor systems, our materials provide exceptional durability where chemical corrosion and thermal stress are most intense.

Key Benefits

- ✓ Extended service life in harsh environments

- ✓ Reduced maintenance downtime

- ✓ Improved energy efficiency

Engineered for Extreme Conditions

Gotrays cement and lime products are specifically formulated to meet the demanding requirements of modern industrial processing equipment.

Learn More About Our SolutionsHigh-Performance Refractory Solutions for Glass Manufacturing

Specialized materials engineered to withstand extreme temperatures and corrosive environments in glass melting furnaces and forming equipment

Superior Thermal Resistance

Our advanced refractory materials maintain structural integrity at temperatures exceeding 1700°C, ensuring consistent glass quality and extended furnace lifespan.

Corrosion Resistance

Withstands aggressive chemical environments in glass melting processes

Thermal Stability

Maintains performance through rapid temperature changes and thermal cycling

Energy Efficiency

Superior insulation properties reduce heat loss and lower energy consumption

Long Service Life

Extended operational lifespan with minimal maintenance requirements

Safety Compliance

Meets all industry safety standards and environmental regulations

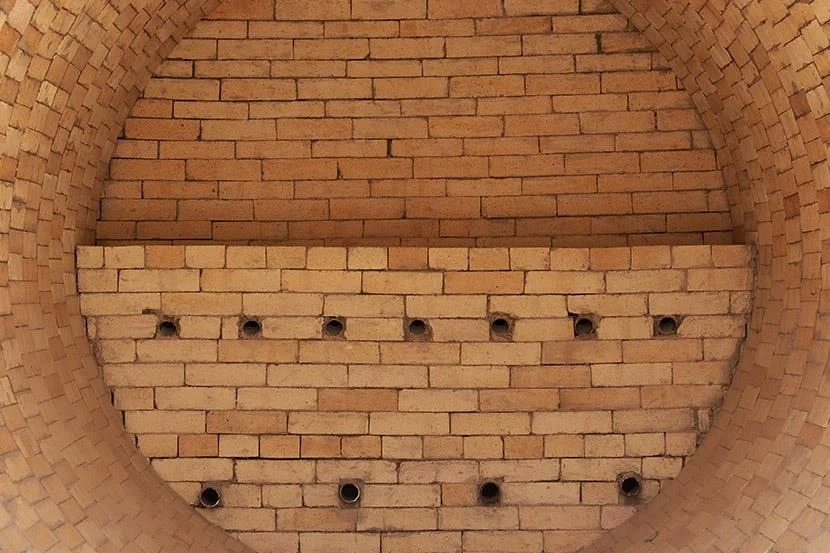

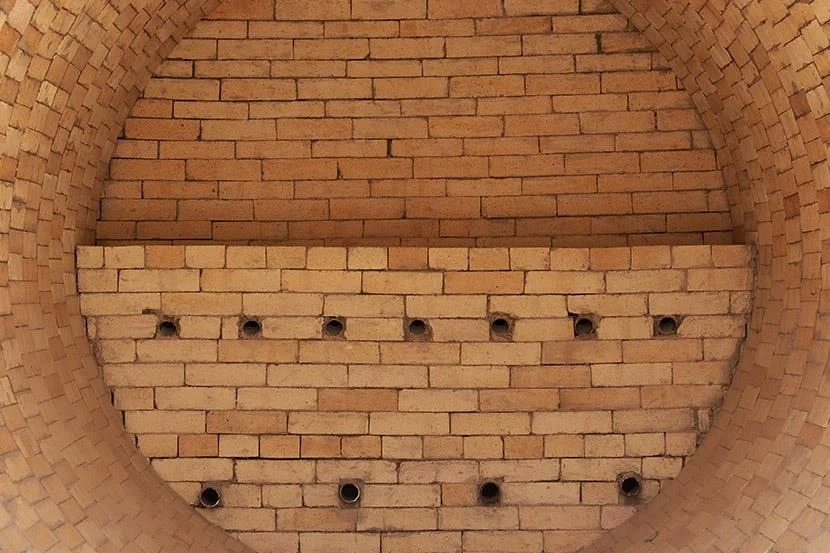

Kiln Furniture & Refractory Solutions

Ensuring thermal stability and consistent quality in ceramics firing through advanced refractory materials and kiln furniture systems.

The Importance of Kiln Furniture

Kiln furniture and refractory linings form the critical infrastructure that supports ceramic ware during firing. These components must withstand extreme temperatures while maintaining structural integrity and thermal stability.

Proper selection of refractory materials ensures consistent heat distribution, minimizes thermal shock, and maintains precise temperature control throughout the firing process—essential factors for achieving uniform product quality and reducing rejects.

Thermal Stability

Maintain consistent temperatures up to 1700°C with our high-alumina refractory materials designed for exceptional thermal shock resistance.

Structural Integrity

Engineered kiln furniture provides reliable support throughout firing cycles, ensuring dimensional stability and preventing product deformation.

Quality Assurance

Rigorous quality control processes guarantee that every refractory component meets industry standards for performance and durability.

Trusted by Ceramics Professionals

Gotrays refractory solutions are engineered to deliver exceptional performance in the most demanding ceramics firing environments, helping manufacturers achieve superior product quality and operational efficiency.

Contact Our ExpertsAdvanced Petrochemical Solutions for Extreme Environments

Gotrays delivers cutting-edge materials engineered for superior performance in reactors, furnaces, and reformers under extreme chemical and thermal conditions.

Unmatched Resistance to Chemical Attack

Our specialized materials provide exceptional protection against corrosive chemicals and aggressive environments, ensuring long-term reliability and reduced maintenance costs.

- • Superior corrosion resistance in acidic and alkaline conditions

- • Excellent stability against chemical degradation

- • Reduced contamination risks in sensitive processes

Extreme Temperature Performance

Engineered to withstand temperatures exceeding 2000°F, our materials maintain structural integrity and performance in the most demanding thermal environments.

- • Exceptional thermal stability and low thermal expansion

- • Reduced heat loss and improved energy efficiency

- • Enhanced thermal shock resistance

Applications Across Petrochemical Processes

Reactors

Lining systems that withstand catalytic reactions and high-pressure conditions

Furnaces

Thermal insulation solutions for cracking furnaces and heating systems

Reformers

Materials optimized for steam methane reforming and other reforming processes

Ready to Enhance Your Operations?

Contact Gotrays today to discover how our advanced materials can improve your petrochemical processing efficiency and reliability.

Contact Our ExpertsAdvanced Boiler & Furnace Linings

Gotrays delivers cutting-edge refractory solutions that withstand extreme thermal stresses and corrosion while maximizing energy efficiency and minimizing downtime.

Thermal Stress Resistance

Our specialized ceramic fiber blankets and refractory materials provide exceptional thermal insulation, reducing heat loss and protecting boiler structures from extreme temperature fluctuations.

- High-temperature stability up to 1600°C

- Reduced thermal cycling damage

- Improved energy efficiency by up to 25%

Corrosion Protection

Our acid-resistant carbon bricks and specialized coatings provide superior protection against corrosive environments, extending equipment lifespan and reducing maintenance costs.

- Chemical resistance to acidic and alkaline conditions

- Extended equipment service life

- Reduced downtime and maintenance costs

Benefits of Gotrays Linings

Energy Efficiency

Reduce heat loss and improve thermal efficiency with our advanced insulation materials.

Durability

Withstand extreme thermal cycling and corrosive environments for longer service life.

Reduced Downtime

Minimize maintenance intervals and maximize operational uptime with reliable performance.

Ready to Improve Your Boiler Performance?

Contact Gotrays today to learn how our advanced lining solutions can enhance your power generation efficiency.

Get StartedAdvanced Refractory Solutions for Hazardous Waste Incineration

Gotrays provides high-performance refractory systems that ensure environmental compliance, operational safety, and durability in extreme waste incineration environments.

Handling Hazardous Waste & Flue Gases

Our specialized refractories withstand corrosive chemicals, extreme temperatures, and thermal cycling in waste-to-energy facilities, maintaining structural integrity while preventing environmental contamination.

Key Benefits:

- • Enhanced corrosion resistance against acidic flue gases

- • Superior thermal shock resistance for operational stability

- • Reduced maintenance downtime and extended service life

Environmental Compliance

Meet strict emission standards with refractory systems designed to contain and process hazardous materials safely.

Operational Safety

Ensure worker safety and process reliability with refractory materials that maintain integrity under extreme conditions.

Energy Efficiency

Optimize thermal performance and reduce energy consumption with advanced insulating refractory solutions.

Ready to Enhance Your Incineration Operations?

Contact Gotrays today to discuss how our refractory solutions can improve your environmental compliance and operational safety.

Advanced Refractory Solutions for Mineral Processing

Gotrays provides high-performance protective linings that extend equipment life in smelting, refining, and heat treatment applications

High-Temperature Furnace Linings

Our specialized refractory materials withstand extreme temperatures in smelting and refining processes, ensuring optimal thermal efficiency and extended equipment lifespan.

- Thermal resistance up to 1700°C

- Chemical corrosion protection

- Reduced maintenance downtime

Castable Linings

Monolithic refractory solutions for complex furnace geometries and rapid installation

Fire Bricks

Traditional brick linings offering excellent thermal stability and mechanical strength

Refractory Cement

High-temperature mortars and cements for sealing and repairing furnace linings

Extend Your Equipment Life

Our protective linings are engineered to withstand the most demanding mineral processing environments

Improved Thermal Efficiency

Reduce energy consumption with superior insulation properties

Enhanced Safety

Protect equipment integrity and ensure operational safety

Reduced Downtime

Long-lasting performance minimizes maintenance interruptions

Advanced Refractory Solutions for Heat Treatment Furnaces

Gotrays delivers high-performance refractory applications that ensure uniform heating and significantly reduce energy consumption in industrial heat treatment processes.

Optimized Thermal Efficiency

Our refractory linings maintain consistent temperatures throughout heat treatment cycles, minimizing heat loss and maximizing energy efficiency for metals and materials processing.

- • Superior thermal insulation properties

- • Reduced energy consumption up to 30%

- • Extended furnace lifespan

Uniform Heating

Consistent temperature distribution across all treatment zones ensures optimal material properties.

Energy Savings

Advanced insulation technology reduces thermal loss and lowers operational costs significantly.

Durability

High-temperature resistant materials withstand extreme conditions and extend maintenance cycles.

Advanced Thermal Management Solutions for Battery Manufacturing

Gotrays provides cutting-edge thermal protection and energy storage material solutions for next-generation battery production processes.

High-Temperature Insulation

Advanced ceramic fiber blankets for superior thermal management in battery production furnaces.

Learn more →

Refractory Linings

Specialized castable linings that withstand extreme temperatures in energy storage material production.

Learn more →

Thermal Protection Systems

Complete thermal management solutions for battery drying and curing processes.

Learn more →

Innovative Thermal Solutions for Energy Storage

Gotrays delivers advanced refractory materials and thermal management systems specifically designed for battery manufacturing and energy storage production. Our solutions ensure optimal temperature control, energy efficiency, and production safety.

Enhanced thermal efficiency for battery production

Superior protection against extreme temperatures

Custom solutions for advanced energy tech production

Precision Thermal Control for High-Tech Material Fabrication

Gotrays photovoltaic semiconductor solutions enable unmatched temperature stability in crystal growth and wafer manufacturing furnaces

Advanced Thermal Management

Our semiconductor technology provides precise temperature control essential for producing high-purity silicon crystals and semiconductor wafers. The system maintains ±0.1°C stability even at extreme temperatures exceeding 1400°C.

This precision ensures consistent crystal structure, reduces defects, and improves yield rates in photovoltaic cell production and advanced material fabrication.

Key Benefits

- • Enhanced crystal purity and structural integrity

- • Reduced thermal stress during manufacturing

- • Improved energy efficiency in furnace operations

- • Long-term temperature stability for continuous processes

±0.1°C Temperature Stability

Energy Efficiency

Reduce energy consumption by up to 30% while maintaining precise thermal conditions for optimal material fabrication.

Quality Assurance

Ensure consistent material quality with stable thermal environments that minimize defects and improve production yield.

Process Optimization

Streamline manufacturing processes with automated thermal control systems that adapt to changing production requirements.

Advanced Refractory Solutions for Rare Earth Processing

Gotrays delivers high-performance refractory materials that ensure purity, efficiency, and durability in next-generation rare earth metal processing.

Ensuring Purity Through Superior Refractory Technology

Our advanced refractory materials provide critical thermal and chemical resistance, maintaining process integrity and preventing contamination in high-temperature rare earth metal processing.

- • High-temperature stability up to 1800°C

- • Chemical resistance to corrosive molten metals

- • Enhanced thermal insulation for energy efficiency

Custom Refractory Formulations

Tailored materials designed specifically for rare earth processing environments and extreme conditions.

Process Efficiency Optimization

Materials that reduce energy consumption and improve thermal efficiency in high-temperature operations.

Contamination Prevention

Advanced coatings and linings that prevent metal contamination and ensure product purity.

Ready to Enhance Your Rare Earth Processing?

Contact our experts to discuss custom refractory solutions for your specific application needs.

Get in TouchPrecious Metals Special Alloys

Critical in melting and refining of high value metals with exceptional heat resistance and contamination avoidance

Advanced Heat Resistance Solutions

Our specialized alloys maintain structural integrity at extreme temperatures, ensuring optimal performance in demanding melting and refining processes.

Engineered to prevent contamination, these alloys protect the purity of precious metals throughout the entire production cycle.

Refractory Linings

Specialized materials that withstand extreme thermal conditions while preventing metal contamination.

Thermal Insulation

Advanced ceramic fiber systems providing superior heat retention and energy efficiency.

Pure Materials

High-purity compounds ensuring zero contamination in precious metal processing environments.

Cemented Carbide Diamond Tools

Premium solutions for tool manufacturing requiring extreme thermal stability, hardness, and durability in high-temperature production environments.

Applications in High-Temperature Tool Manufacturing

Our cemented carbide diamond tools are engineered to maintain structural integrity and cutting performance in stable heat environments, ensuring consistent quality throughout production processes.

Thermal Stability

Maintains hardness and precision in continuous high-temperature operations

Enhanced Durability

Resists wear and deformation under extreme production conditions

Precision Engineering

Consistent performance for critical manufacturing applications

Heat Resistance

Specially formulated to withstand temperatures exceeding 1000°C without compromising structural integrity.

Longevity

Extended tool life reduces production downtime and maintenance costs in demanding manufacturing environments.

Quality Assurance

Rigorous testing ensures every tool meets the highest standards for precision and reliability in thermal applications.

Refractory Excellence in Glass Quartz Processing

Thermal and chemical stability for superior quality control in high purity quartz and specialty glass manufacturing

Critical Refractory Roles

Refractory materials serve as the backbone of high-temperature processing systems, providing essential thermal insulation and chemical resistance that ensures product purity and manufacturing consistency.

Thermal Stability

Withstanding extreme temperatures up to 1800°C while maintaining structural integrity

Chemical Resistance

Preventing contamination from molten glass and quartz reactions

Quality Assurance

Ensuring consistent thermal profiles for precise manufacturing control

Gotrays Refractory Systems

Engineered for precision thermal management

High Purity Applications

Specialized refractories for semiconductor-grade quartz and optical glass manufacturing

Thermal Management

Precise temperature control systems for consistent melting and forming processes

Quality Control

Advanced monitoring and control systems ensuring manufacturing excellence

Precision Furnace Solutions for Semiconductor & LED Production

Advanced furnace linings and heat treatment technologies by Gotrays ensuring precision temperature control for consistent manufacturing results

LED Sapphire Furnace Linings

Our specialized refractory materials maintain extreme temperature stability critical for sapphire crystal growth and LED production processes.

- Precision temperature control ±1°C

- Superior thermal insulation properties

- Chemical resistance to process gases

Thermal Stability

Maintain consistent temperatures up to 1800°C for perfect crystal growth

Quality Consistency

Ensure uniform heat distribution for batch-to-batch reproducibility

Longevity

Extended furnace lining lifespan reducing downtime and maintenance costs

Trusted by Leading Semiconductor Manufacturers

Gotrays furnace solutions power the production of next-generation semiconductors and high-efficiency LEDs

Contact Our Engineering TeamWhy Industry Leaders Choose Refractory Solutions

Discover how advanced refractory materials optimize industrial processes, enhance reliability, improve energy efficiency, and ensure operational safety.

Process Reliability

Withstand extreme temperatures and chemical corrosion, ensuring continuous operation and minimizing downtime in demanding industrial environments.

Energy Efficiency

Superior thermal insulation properties reduce heat loss, lower energy consumption, and optimize thermal management in industrial processes.

Operational Safety

Provide critical protection against heat transfer, contain hazardous materials, and prevent structural failures in high-risk industrial settings.

Experience the Gotrays Difference

Join industry leaders who trust our refractory solutions for superior performance, durability, and cost-effectiveness.

Unlock Deeper Application Insights

Explore comprehensive data analytics and expert consultation to optimize your industrial processes. Our specialized insights help you achieve superior performance and efficiency.