What Are Quartz Ceramic Rods A Complete Guide

Quartz ceramic rods are high-purity rods made primarily from fused silicon dioxide (SiO2). Unlike crystalline quartz, which has an ordered atomic structure, fused SiO2 is an amorphous, non-crystalline glass. This difference gives quartz ceramic rods unique thermal and chemical properties. Over time, these rods evolved from simple laboratory tools used for stirring and heating to essential components in semiconductor manufacturing and fiber optic industries.

Are quartz ceramic rods the same as fused silica rods? While often used interchangeably, “quartz ceramic rods” generally refer to rods made from fused silica, highlighting their ceramic-like durability and purity. Fused silica rods are a type of quartz ceramic rod with superior optical clarity and thermal shock resistance.

Understanding this distinction helps guide the right selection for high-precision applications. Explore more to see why these rods are trusted across advanced industries.

Unmatched Properties of Gotrays Quartz Ceramic Rods

Gotrays Quartz Ceramic Rods stand out for their exceptional performance in tough environments. Here’s why they’re trusted by labs and factories across the U.S.:

Thermal Stability and Shock Resistance

- With a thermal shock resistance that surpasses many alternatives, our quartz ceramic rods can handle rapid temperature changes without cracking.

- Tested to withstand temperatures above 1200°C (2200°F), they maintain strength and shape where others fail.

Chemical Inertness

- Our rods resist most acids and harsh chemicals, making them ideal for lab use and metalworking.

- Check our acid resistance charts showing minimal degradation when exposed to strong acids and solvents.

Optical and Electrical Excellence

- Gotrays rods are UV transparent, allowing them to transmit ultraviolet light clearly — perfect for semiconductor and fiber optics applications.

- They offer excellent electrical insulation, supporting sensitive equipment without interference.

Gotrays vs Competitors Alumina Rods Comparison

| Feature | Gotrays Quartz Ceramic Rods | Standard Alumina Rods |

|---|---|---|

| Thermal Shock Resistance | High – withstands rapid changes | Moderate – prone to cracking |

| Chemical Resistance | Excellent against acids and solvents | Good but reacts with some acids |

| UV Transparency | High – ideal for optics | Low – blocks UV light |

| Electrical Insulation | Superior | Standard |

| Price | Competitive | Similar or higher |

When you choose Gotrays quartz ceramic rods, you get unmatched durability and performance designed specifically for demanding industrial and lab environments right here in the U.S.

Top Applications for Quartz Ceramic Rods in Modern Industry

Quartz ceramic rods are essential across several industries thanks to their unique properties.

Semiconductor and Fiber Optics

- Used for wafer boats and alignment rods to handle delicate silicon wafers without contamination.

- Ideal for fiber optics manufacturing, where precision and purity are critical.

Lab and Metalworking

- Perfect as high-purity quartz stirring rods for mixing chemicals without causing reactions.

- Widely used in metalworking for molten metal stirring and processes like jewelry casting, where the rod’s resistance to heat and chemicals protects the final product.

High Temperature Processes

- Common in devices like thermocouples where reliable temperature measurement is vital.

- Used in kiln fixtures and other high-temp industrial applications where heat shock resistance and durability are needed.

Quartz ceramic rods stand out because they combine heat resistance, chemical inertness, and optical clarity, making them a go-to tool across labs, manufacturing floors, and high-tech production lines.

Why Choose Gotrays Our Commitment to Quality and Innovation

At Gotrays, we bring over 10 years of experience in crafting high-quality quartz ceramic rods. Our deep roots in ceramics mean we understand exactly what the U.S. market needs—durable, reliable rods made with sustainable sourcing from start to finish. We take pride in blending innovation with eco-friendly practices to deliver products that meet both performance and environmental standards.

We back our quartz ceramic rods with rigorous certifications and testing protocols to ensure every piece performs as promised. Whether it’s thermal shock resistance, chemical inertness, or optical clarity, our rods pass all the critical metrics before they reach you.

Because we work closely with local industries—from Texas fabs to California labs—we get the workflow and budget demands. That’s why we offer bulk discounts and straightforward return policies, making it easy to order with confidence. Gotrays isn’t just about selling rods; it’s about building partnerships that help your business thrive.

Specifications and Customization Options for Quartz Ceramic Rods

At Gotrays, we offer a wide range of quartz ceramic rod sizes and customizations to fit your exact needs. Whether you need standard rods or something designed specifically for your application, we’ve got you covered.

Standard vs Custom Quartz Ceramic Rods

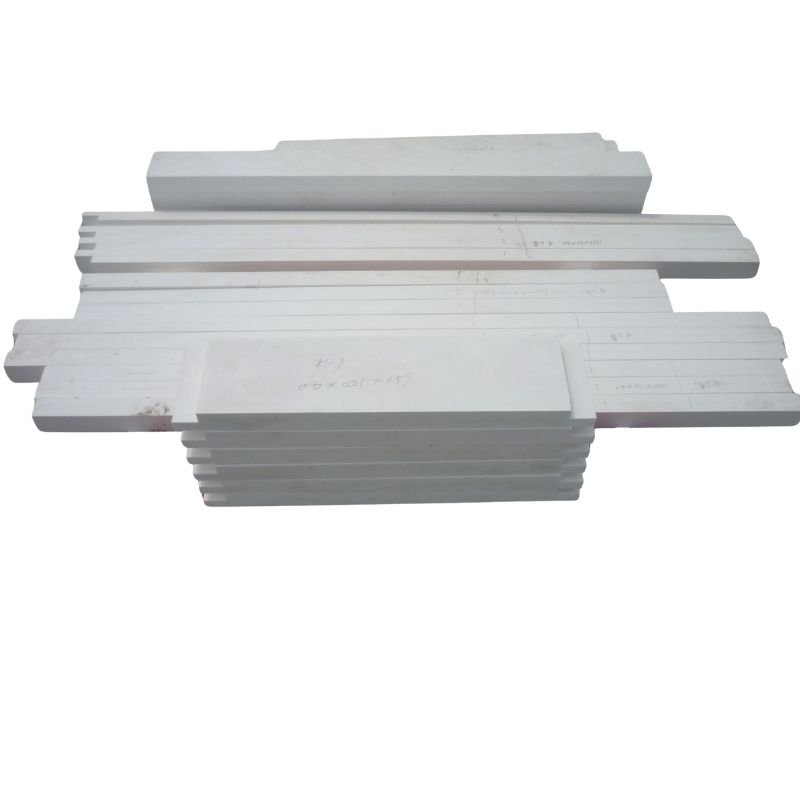

- Standard Rods

- Diameter: 3mm to 25mm

- Length: 50mm to 300mm

- Smooth, polished finish ideal for general use in labs, metalworking, and semiconductor handling.

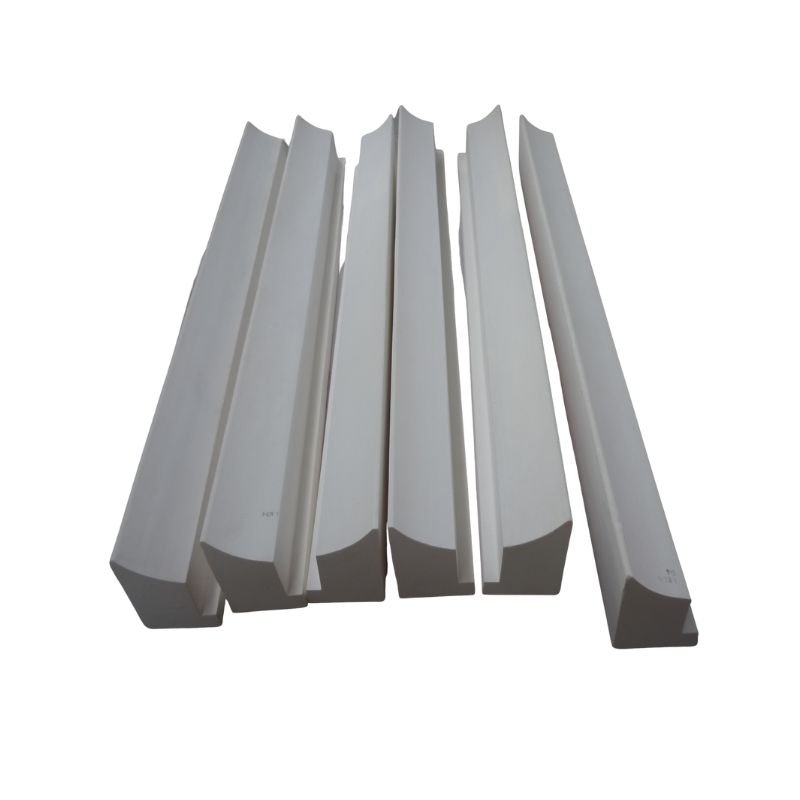

- Custom V-Grooved Rods

- Perfect for fiber optics or semiconductor wafer alignment

- V-grooves precision cut to your required dimensions

- Helps secure and align delicate parts during processing

Additional Customization Options

- Lengths tailored beyond the standard range

- Polishing grades from matte to optically clear

- Custom diameters and shapes on request

- Special thermal or chemical coatings available

Tool Size Calculator

To make ordering easier, we provide an embedded online tool size calculator on our product pages. Just enter your project specs (diameter, length, grooves), and it helps you select the perfect rod size and customization. This feature is especially handy for local Texas fabs and California labs needing fast and accurate orders.

By offering detailed specs and online tools, Gotrays ensures you get the quartz ceramic rod that fits your workflow perfectly—no guesswork, no delays.

How to Buy Quartz Ceramic Rods from Gotrays Simple Steps

Buying quartz ceramic rods from Gotrays is straightforward and designed to fit your busy schedule. Here’s how to get started:

Step-by-Step Guide from Quote to Delivery

- Request a Quote: Visit our website or call our Texas-based customer support to get a fast quote tailored to your needs—whether it’s standard fused silica rods or custom sizes.

- Place Your Order: Once you approve the quote, place your order online or by phone. We handle everything quickly to keep your projects on track.

- Order Processing: Our team begins custom fabrication or pulls from stock, ensuring quality checks at every stage.

- Shipping and Delivery: We offer fast shipping options, including overnight delivery to California labs and other local fabs. You’ll get tracking info to monitor your order in real time.

Transparent Pricing and Volume Discounts

- Pricing is clear upfront with no hidden fees.

- We offer volume tiers, so buying more saves you money.

- Use our online freight calculator to estimate shipping costs quickly.

At Gotrays, we make sure buying high-purity quartz ceramic rods fits your workflow and budget without hassle. Whether you’re in Texas, California, or anywhere in the U.S., we’ve got your back with fast, reliable service.

Real Results Customer Success Stories

At Gotrays, we stand behind the performance of our quartz ceramic rods. Customers across Texas, California, and beyond have shared real success stories showing how our products make a difference in their processes.

Key Highlights from Our Customers:

Reduced Replacement Costs

Many semiconductor fabs and fiber optics labs report longer rod lifespans thanks to the thermal shock resistance and chemical inertness of our quartz ceramic rods. One California wafer fab cut replacement frequency by 30%, saving thousands annually.

-

Improved Process Efficiency

Metalworking shops using our high-purity quartz stirring rods noticed cleaner melts and fewer impurities, helping their casting quality improve with less downtime.

-

Consistent Performance Under High Temperatures

Customers running kiln fixtures and thermocouples in harsh environments highlight our rods’ stability without warping, increasing uptime and reducing equipment failures.

Customer Videos and Testimonials

We also feature video testimonials where operators explain how using Gotrays quartz rods solved common headaches like cracking, contamination, and UV transmission loss. These stories give a transparent look at how our products perform in real-world settings.

If you want reliable quartz ceramic rods that deliver measurable results — hear it from those who use them every day. Our commitment to quality isn’t just a claim; it’s backed by data and proven in the field.

Frequently Asked Questions FAQ

Here are answers to some common questions about quartz ceramic rods to help you out.

Are quartz ceramic rods the same as fused silica rods?

No, they’re closely related but not identical. Quartz ceramic rods are made from high-purity fused SiO2 but processed differently to enhance thermal and mechanical properties. Fused silica rods are usually clearer but less tough under stress.

What is the maximum diameter available?

Our standard quartz ceramic rods go up to 25 mm in diameter. Custom sizes are available on request depending on your needs.

How do I clean my quartz ceramic rod?

Use mild detergent and warm water for general cleaning.

Avoid harsh acids or abrasive materials to keep the surface smooth.

For stubborn residues, a quick rinse with isopropyl alcohol works well.

What if my rod cracks or chips?

Quartz ceramic rods are designed for thermal shock resistance but still, accidents happen. Contact us for replacement policies. Proper handling includes avoiding sudden temperature changes and mechanical impacts.

How long does procurement usually take?

We keep stock in Texas and California for fast delivery, typically 3–5 business days for standard sizes. Custom rods might take 2-3 weeks depending on specs.

Can I get volume discounts?

Yes, bulk pricing is available. Just reach out with your order size, and we’ll provide a quote.

Troubleshooting rod performance issues

- If rods seem less durable, check for overheating or misuse.

- Ensure rods aren’t exposed to chemicals outside their resistant range.

- Confirm proper alignment when used in wafer handling or stirring to reduce mechanical stress.

Still got questions? Contact our team for expert advice tailored to your local U.S. industry needs.

Reviews

There are no reviews yet.