What is a Quartz Ceramic Nozzle Essential Guide for Manufacturers

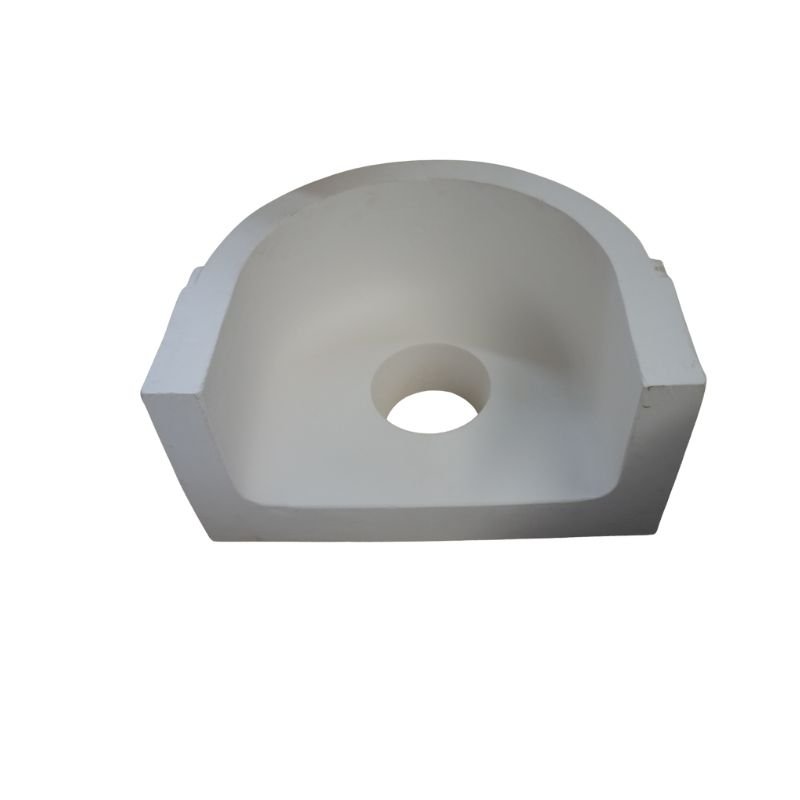

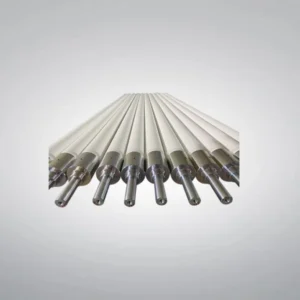

A quartz ceramic nozzle is a precision-engineered component used in hot runner injection molding systems. It channels molten plastic from the hot runner manifold into molds with high accuracy, enabling efficient production of plastic parts. Made primarily from fused silica—also known as quartz ceramic—these nozzles combine the thermal stability of quartz with the hardness and durability of advanced ceramics.

The composition of a quartz ceramic nozzle typically includes fused silica, known for its excellent thermal shock resistance and low thermal expansion, paired with ceramic bonding agents that enhance mechanical strength and abrasion resistance. This unique blend leads to nozzles that maintain dimensional stability and resist wear in high-temperature, high-pressure molding environments.

Historically, injection molding nozzles were made from metal alloys such as stainless steel or aluminum. Although metals provided good thermal conductivity, they suffered from wear, corrosion, and thermal fatigue over repeated cycles. The evolution to quartz ceramic materials began as manufacturers sought nozzles that could withstand higher temperatures and abrasion while minimizing downtime. Quartz ceramic’s low thermal expansion reduces the risk of cracking, while its abrasion resistance and chemical inertness improve nozzle lifespan. This shift has been key for industries demanding precision and durability, like automotive and medical device manufacturing.

When sourcing quartz ceramic nozzles, manufacturers face choices between local suppliers in the US and import options from Asia. US-based sources typically offer quicker lead times, tighter quality control, and easier customization to align with regional mold standards. Asian suppliers may provide cost advantages but come with longer shipping and varied quality levels. For manufacturers prioritizing reliability and integration with US production lines, partnering with domestic suppliers like Gotrays offers distinct benefits in service, support, and compliance.

Key Features of Gotrays Quartz Ceramic Nozzles

Gotrays Quartz Ceramic Nozzles stand out for their precision, durability, and efficiency. They’re built with advanced fused silica ceramic—a tough material known for its high thermal shock resistance and low thermal expansion. This means less downtime and fewer replacements for your hot runner system.

Detailed Specs

| Feature | Specification |

|---|---|

| Material | Fused Silica Quartz Ceramic |

| Operating Temperature | Up to 1000°F (538°C) |

| Bore Sizes | Customizable from 2mm to 8mm |

| Thread Type | M10 standard with torque specs |

| Abrasion Resistance | High, ideal for abrasive resins |

| Thermal Shock Proof | Excellent, reduces cracking risks |

Quartz Fusion Process and Ceramic Bonding

Gotrays nozzles use a quartz fusion process that melts high-purity quartz particles into a uniform, dense ceramic. This creates a smooth inner surface that reduces resin build-up and improves flow consistency. The ceramic bonding technique used ensures the nozzle withstands thermal cycling without cracking or warping—critical for maintaining performance over time.

Customization Options

We understand that one size doesn’t fit all. Gotrays offers bore sizing customization to meet various regional mold standards commonly used in the U.S. Whether you need a smaller bore for precision molding or a larger one for high-volume runs, we tailor the nozzle to fit your production specs. This flexibility helps optimize shot accuracy and reduces waste across different injection molding setups.

Top Benefits Why Upgrade to Quartz Ceramic for Your Hot Runner System

Switching to a quartz ceramic nozzle in your hot runner system brings clear advantages that add up fast.

Quantified Savings

Quartz ceramic nozzles last longer than traditional metal ones, cutting replacement costs by up to 40%.

They resist thermal shock and abrasion, meaning fewer stops for maintenance and more uptime.

On average, using Gotrays Quartz Ceramic Nozzles saves manufacturers around $5,000 annually just on reduced downtime and parts replacement.

Real Results

Take the example of a Midwest plastics firm that upgraded to Gotrays Quartz Ceramic Nozzles. They saw a 35% drop in production downtime. Less downtime means more output, better order fulfillment, and improved profits.

Environmental Compliance

Our nozzles meet strict RoHS standards required by the EU, so they’re safe for environmentally conscious manufacturers. They help keep your process green by reducing waste from frequent replacements.

Upgrading to quartz ceramic isn’t just smart for your bottom line — it’s a long-term solution that keeps your hot runner system running smooth and clean.

Applications Across Industries Where Gotrays Excels

Gotrays Quartz Ceramic Nozzles are built to handle tough jobs across multiple industries. Here’s where they really shine:

Injection Molding Focus on PET and ABS Resins

Our nozzles deliver consistent flow and precision for high-demand injection molding, especially with PET and ABS resins. These materials require stable temperatures and wear resistance, which quartz ceramic nozzles provide better than traditional metal options. That means fewer defects and smoother runs on your production line.

Niche Uses in Automotive and Medical Packaging

In automotive parts manufacturing, Gotrays nozzles withstand high temperatures and resist abrasion from tough resins used in dashboards or connectors. For medical packaging, their purity and thermal shock resistance meet strict quality standards, ensuring sterile, dependable mold results.

Regional Spotlight for High-Volume US Production

We understand the US manufacturing scene—fast turnaround and durability matter most here. Gotrays Quartz Ceramic Nozzles are designed for high-volume American production lines, minimizing downtime and replacement costs. Local sourcing of materials and manufacturing means quicker supply times and support for your operation.

By choosing Gotrays, you’re aligning your processes with a nozzle that is tailored for your industry’s challenges and the demands of the US market.

Gotrays vs Competitors Side by Side Comparison

When choosing the right nozzle for your hot runner system, it pays to weigh your options carefully. Here’s a quick look at how Gotrays Quartz Ceramic Nozzles stack up against traditional metal nozzles and other ceramic options.

| Feature | Gotrays Quartz Ceramic Nozzle | Traditional Metal Nozzle | Other Ceramic Nozzles |

|---|---|---|---|

| Heat Resistance | Up to 1200°F, thermal shock proof | Up to 1000°F, prone to warping | Similar to Gotrays but less consistent |

| Abrasion Resistance | Excellent, reduces wear on gate tips | Moderate, metal wears faster | Good but varies by manufacturer |

| Customization Options | Custom bore sizing for US standard molds | Limited customization | Custom but often costly |

| Downtime Reduction | Proven 35% downtime reduction in case studies | Higher replacement frequency | Variable performance |

| Environmental Compliance | RoHS certified for EU and US regulations | Typically not compliant | Depends on manufacturer |

| Price Point | Competitive with long-term ROI | Lower upfront cost but higher maintenance | Generally higher upfront cost |

| User Feedback | High satisfaction, especially in US plants | Mixed reviews due to durability concerns | Positive but less available in US market |

User Poll Results

We asked industry professionals: For your next hot runner nozzle, would you pick Quartz Ceramic or Metal?

- Quartz Ceramic Nozzle: 68%

- Metal Nozzle: 32%

This clear preference highlights the growing trust in quartz ceramic nozzles for their durability and performance, especially in demanding US production environments.

Why Gotrays Stands Out

- Superior thermal and abrasion resistance ideal for high-volume molding lines

- Custom bore options mean tighter fits for regional mold standards

- Strong focus on US customers with local support and fast delivery

If you want a nozzle that saves you money on downtime and replacements, Gotrays Quartz Ceramic Nozzles make a strong case compared to metal and other ceramic alternatives.

Installation and Maintenance Best Practices

Getting your Gotrays Quartz Ceramic Nozzle installed right the first time saves headaches down the road. Here’s a simple step-by-step guide to help you set up and maintain your nozzles for peak performance.

Step by Step Installation Guide

- Clean the nozzle and hot runner plate before installation to remove dust and debris.

- Align the nozzle correctly to ensure the bore matches the mold’s sprue and gate.

- Torque specs for M10 threads: Tighten bolts to 25–30 Nm. Use a torque wrench to avoid over-tightening, which can crack the ceramic.

- Check for proper seating by visually inspecting the interface and running a short test cycle for flow consistency.

- Avoid sudden temperature shocks during startup by gradually ramping temperatures to prevent thermal stress.

Maintenance Tips

- Regular visual inspections: Look for cracks, chips, or deposits on the nozzle surface.

- Clean regularly with non-abrasive methods to keep the flow smooth and prevent buildup.

- Replace seals and O-rings at every maintenance cycle to avoid leaks.

- Monitor flow rates for signs of blockage or wear on the bore.

Troubleshooting Common Flow Issues

- Uneven flow or short shots: Check nozzle alignment and ensure the bore is clean.

- Material degradation or burning: Lower the temperature gradually and check for trapped moisture in the resin.

- Leaks around the nozzle: Verify torque settings and inspect sealing components.

- Frequent nozzle clogging: Consider upgrading the bore size or switching resin grades to reduce residue buildup.

Video Transcript for Accessibility

Here’s a brief transcript excerpt from our installation video demonstrating correct torque application and flow checks:

“Start by positioning the quartz ceramic nozzle carefully in the hot runner plate. Use a calibrated torque wrench to tighten M10 bolts slowly, aiming for 28 Nm. Avoid quick temperature spikes in the machine to protect the ceramic material from cracking. After installation, run a 3-cycle test to ensure smooth resin flow and no leaks before full production.”

Following these steps helps you maximize uptime and get the most out of your Gotrays Quartz Ceramic Nozzle in your local US molding facilities.

Frequently Asked Questions FAQ

1. What is the price per unit for Quartz Ceramic Nozzles when bought in bulk?

Prices vary depending on quantity and customization, but bulk orders typically reduce the cost by 15-25%. Contact Gotrays for a personalized quote.

2. Are Gotrays Quartz Ceramic Nozzles compatible with Synventive hot runners?

Yes, Gotrays nozzles are designed to fit most popular hot runner systems, including Synventive models.

3. Can I customize the bore size of a quartz ceramic nozzle?

Absolutely. Gotrays offers custom bore sizing to match regional mold standards and specific production needs.

4. How resistant are quartz ceramic nozzles to thermal shock?

Our nozzles are thermal shock proof, handling sudden temperature changes better than traditional metal nozzles.

5. What materials are these nozzles best suited for?

They perform exceptionally well with resins like PET and ABS, common in injection molding.

6. How much downtime can I expect to save by switching to a quartz ceramic nozzle?

Many customers report up to a 35% reduction in downtime due to less frequent nozzle replacements and clogging.

7. Are these nozzles compliant with environmental standards like RoHS?

Yes, Gotrays Quartz Ceramic Nozzles meet RoHS requirements, making them safe for use in EU-regulated markets.

8. What’s the typical lead time for an order shipped within the US?

Standard orders ship within 5-7 business days. Custom orders may take 10-14 days depending on specs.

9. How durable are these nozzles compared to aluminum or traditional ceramic nozzles?

Quartz ceramic nozzles are more abrasion resistant and last significantly longer under high-temp, high-pressure runs.

10. Can Gotrays nozzles be used for niche industries like automotive or medical packaging?

Yes, they’re widely adopted in automotive parts molding and medical-grade packaging applications due to high precision and durability.

11. Is there technical support available for installation and troubleshooting?

Yes, Gotrays provides detailed guides, video tutorials, and direct support to ensure a smooth setup.

If you have more questions, reach out to our team anytime—we’re here to help you get the most from your hot runner system.

Customer Success Stories and Reviews

Midwest Plastics Cut Downtime by 35%

A leading Midwest plastics manufacturer switched to Gotrays Quartz Ceramic Nozzles and saw a drastic drop in their downtime. By upgrading from traditional metal nozzles, they reduced replacement frequency by 40%, saving over $20,000 annually. Their hot runner systems ran smoother, and the abrasion-resistant molding nozzle improved part quality consistently.

Southern Packaging Firm Boosts Output by 25%

One large packaging company in the South upgraded their injection molding lines with Gotrays custom bore ceramic nozzles. The precision ceramic sprue bushing ensured better melt flow control, increasing cycle times and output by 25%. Their ROI was visible within six months, and they appreciated the thermal shock-proof nozzle’s durability in demanding production conditions.

Medical Device OEM Achieves Compliance and Quality Gains

A medical device manufacturer needed hot runner gate tips that met strict RoHS and FDA standards for their plastic components. Gotrays alumina quartz nozzles hit all their compliance needs while offering enhanced heat resistance and flow precision. They shared that since switching, scrap rates fell by 15%, and quality audits consistently passed without issue.

Share Your Gotrays Install #QuartzNozzleWins

We love hearing from users across the U.S. about how Gotrays Quartz Ceramic Nozzles improve their operations. Share your stories, photos, and tips using #QuartzNozzleWins on social media. Connect with other manufacturers and join the growing community choosing durability and precision for their hot runner systems.

Ready to Optimize Your Molding Shop with Gotrays Quartz Ceramic Nozzles Today

If you’re looking to boost your molding efficiency and cut downtime, Gotrays Quartz Ceramic Nozzles are the smart choice. Designed for durability, thermal shock resistance, and precision, these nozzles fit perfectly into high-volume production lines across the U.S., helping you save time and money.

Get a custom quote now to see how upgrading can impact your bottom line. Sign up for our newsletter to get the latest updates on new products, tips, and industry news straight to your inbox.

Related reads:

- Hot Runner Buyer’s Guide — Your go-to resource for choosing the best components for your system.

- How to Maximize Hot Runner System Efficiency — Practical steps for long-term savings.

Optimize your process today with Gotrays Quartz Ceramic Nozzles and experience the difference in performance and reliability.

Reviews

There are no reviews yet.