NB-SiC Refractory Beam Product Spotlight

Looking for a reliable solution to support your high-temperature kiln operations? Our Nitride Bonded Silicon Carbide (NB-SiC) Refractory Beams deliver unmatched strength and durability exactly where you need it most. Engineered for industrial furnace support and kiln shelf beams, these high-temp SiC load bearing beams excel even in the toughest ceramic firing and metallurgy environments.

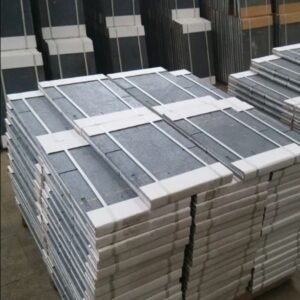

Explore our high-resolution images below to see the precision and quality that set our NB SiC beams apart. Each beam combines advanced reaction sintered SiC technology with superior oxidation resistance and thermal shock proof design.

Key Stats at a glance:

- Operating temperatures up to 1600°C

- Exceptional thermal shock resistance

- High mechanical strength load capacity

- Custom sizing available for kiln furniture supports

Ready to reduce downtime and enhance your kiln’s performance? Click below to get your custom quote and take the first step toward upgrading your refractory solutions today.

Product Overview

Our NB-SiC Refractory Beams are made from nitride bonded silicon carbide, combining the strength of SiC with enhanced durability thanks to the unique bonding process. These beams are designed specifically as kiln support beams, providing reliable load-bearing support for high-temperature industrial furnaces and ceramic kilns.

Thanks to their composition, NB SiC beams handle extreme heat, resist oxidation, and stand up to thermal shock — making them a go-to choice for U.S. manufacturers wanting dependable kiln furniture supports that last longer and reduce downtime.

Quick Specs

| Property | Value |

|---|---|

| Material | Nitride Bonded Silicon Carbide (NB SiC) |

| Max Operating Temperature | Up to 3000°F (1650°C) |

| Density | Approx. 2.85 g/cm³ |

| Thermal Shock Resistance | Excellent |

| Oxidation Resistance | Very High |

Watch it in action

[Embedded Video: NB-SiC Refractory Beam Performance]

See how our high-temp SiC load bearing beams perform under harsh kiln conditions and why they’re the trusted choice for refractory cross beams in ceramics and metallurgy.

Key Features and Benefits of NB SiC Refractory Beam

Our NB-SiC Refractory Beams stand out for their unmatched thermal shock resistance, making them perfect for kiln environments where rapid temperature changes are common. This means less cracking and longer service life, helping you avoid costly downtime.

They also offer excellent oxidation and wear resistance. The Nitride Bonded Silicon Carbide material holds up strong against harsh kiln atmospheres, reducing maintenance and replacement frequency.

With superior mechanical strength, these beams support heavy loads without bending or breaking. This strength ensures stable kiln furniture and consistent firing results, which is crucial for industries like ceramics and metallurgy.

The beams feature chemical inertness, meaning they won’t react with kiln atmospheres or materials during firing. This preserves product quality and extends beam lifespan.

We’re also proud of the eco-friendly design of our NB SiC beams. Made with sustainable processes, they contribute to greener manufacturing without sacrificing performance.

All these features translate into real benefits for your operation:

- Reduced kiln downtime thanks to durable, thermal shock–proof beams

- Fewer replacements due to oxidation and wear resistance

- Consistent firing quality supported by strong, stable beams

- Lower overall costs by minimizing maintenance and waste

For customers in the U.S., who demand reliable, long-lasting kiln furniture supports, our NB SiC beams deliver exactly what you need to keep production running smoothly.

Technical Specifications of NB-SiC Refractory Beam

Our NB-SiC refractory beams are designed to meet the demanding needs of high-temperature industrial processes. Here’s a quick breakdown of their key properties and available options:

| Property | Value | Test Method |

|---|---|---|

| Density | 2.9 – 3.1 g/cm³ | ASTM C373 |

| Modulus of Rupture | 40 – 60 MPa | ASTM C133 |

| Thermal Shock Resistance | 10+ cycles at 1500°F (815°C) | Thermal cycling test |

| Oxidation Resistance | Excellent up to 3000°F (1650°C) | High-temp oxidation ASTM |

| Porosity | < 5% | ASTM C20 |

| Hardness | 1500 – 1800 HV | Vickers Hardness test |

Dimensional Options and Grades

- Standard Sizes: Lengths from 12” to 48”, cross-sections from 2”x2” up to 6”x6”

- Custom Dimensions: Available for specific project needs via our configurator

- Material Grades:

- Standard Grade NB-SiC: Ideal for typical kiln furniture and load-bearing applications

- Premium Grade Reaction Sintered SiC (RS-SiC): Enhanced mechanical strength and oxidation resistance for harsh environments

Each batch is tested to confirm consistent performance and traceability, ensuring dependable quality across all shipments. Whether replacing existing kiln shelf beams or upgrading for better durability, our NB-SiC refractory beams come with the specs you need to keep your operations smooth.

Applications and Use Cases

Our NB-SiC refractory beams are built to handle tough jobs across several industries. They’re a perfect fit for ceramics kilns, especially those firing sanitary porcelain where durability and thermal stability matter most. In metallurgy, these beams support non-ferrous metal melting processes, offering strong load-bearing capacity at high temperatures without cracking or warping.

Refractory tunnel kilns also benefit from Nitride Bonded Silicon Carbide Beams because they withstand consistent thermal cycling and resist oxidation over time, reducing downtime and maintenance needs.

Key use cases include:

- Kiln furniture supports for ceramics firing

- High temperature load bearing in industrial furnace setups

- Refractory cross beams in roller kiln and tunnel kiln applications

Check out our case studies to see how these beams improve kiln lifespan and performance in real-world U.S. manufacturing settings. Plus, our NB SiC beams are compatible with common kiln shelf systems, making them easy to integrate into your current setup.

Quality Assurance and Certifications

We stand behind every NB-SiC refractory beam with strict quality control measures designed for durability and performance. Our manufacturing process meets ISO 9001 certification, ensuring consistent quality you can trust.

To guarantee reliability in tough environments, our beams undergo rigorous thermal shock cycle testing, so they hold up under rapid temperature changes without cracking or deforming. Each batch is traceable with unique coding, giving you full confidence in product origin and consistency.

Our transparent process is easy to follow with the manufacturing infographic, showing every step from raw materials to final inspection. This level of control means you get oxidation resistant refractory beams built to last, perfect for demanding industrial furnace support needs across the U.S.

Customization and Sizing Guide

We know every kiln setup is different, so our NB-SiC refractory beams come with flexible sizing and shape options to fit your needs. Use our interactive configurator online to quickly customize dimensions, shapes, and surface finishes. Whether you need standard rectangular beams, tapered cross beams, or custom profiles for roller kilns, we can handle it.

Choose from multiple surface finishes designed to improve performance and durability in your specific application. Our team works closely with you to recommend the best options based on your kiln type and firing conditions.

Typical lead times range from 4 to 6 weeks, depending on customization level and quantity. We prioritize fast turnaround for U.S. customers to minimize downtime and keep your operations running smooth.

- Custom lengths, widths, and thicknesses

- Variety of surface finishes like smooth or textured

- Special shapes for unique kiln designs

- Fast and reliable shipping across the U.S.

Reach out anytime to get started on your custom NB SiC beam order. Our goal is to deliver the exact support solution you need to boost kiln performance.

Pricing and Purchasing

We offer tiered pricing on our NB-SiC refractory beams, so the more you buy, the more you save. Whether you need a few pieces or large volume orders, we provide competitive rates tailored to your project size.

To get your custom quote, just fill out our easy online form. Our team is ready to assist with bulk orders, ensuring you get the right beams at the best price.

We ship across the United States and globally, with reliable delivery options to meet your schedule. From small ceramic kiln supports to large industrial furnace beams, we make ordering seamless and hassle-free.

Customer Testimonials and Resources

See why U.S. manufacturers trust our NB-SiC refractory beams for their kiln supports and furnace needs.

What Our Customers Say

- “These nitride bonded silicon carbide beams held up perfectly in our high-temp ceramic kilns—zero downtime.” — CeramicWorks, TX

- “The oxidation resistance and strength of these kiln furniture supports saved us time and money on replacements.” — MetalMelters Inc., OH

- “Custom sizing options made it easy to fit our refractory tunnel kilns. Highly recommend.” — ThermalProcess Group, CA

Resources at Your Fingertips

- Download detailed datasheets with specs and test results

- Access our handy FAQ for quick answers about installation, sizing, and maintenance

- Contact support for expert guidance on selecting the right SiC refractory beam for your needs

We’re here to help you get the most from your investment in high-temp SiC load bearing beams.

Stay Connected and Explore More

Don’t miss out on the latest updates about our NB-SiC refractory beam products and industry news. Sign up for our newsletter to receive exclusive offers, tech tips, and product launches directly to your inbox.

Related Products

Browse our selection of Nitride Bonded Silicon Carbide Beams and other kiln furniture supports designed to meet your high-temperature needs. Check out the carousel below for quick access to compatible and alternative refractory solutions.

Need Help?

Have questions or ready to place an order? Reach out anytime. Our team is available via live chat or phone to provide expert advice and fast support tailored to your industry requirements.

Reviews

There are no reviews yet.