Gotrays Molybdenum Disilicide MoSi₂ Heating Elements High Temp Reliability for Industrial Furnaces

Gotrays offers Molybdenum Disilicide (MoSi₂) heating elements designed for demanding high-temperature industrial applications. Known for their outstanding oxidation resistance and ability to operate reliably at temperatures up to 1800°C, these heating elements provide a durable solution for modern furnace systems. Whether you need standard shapes like U-shaped or W-type MoSi₂ heating rods or custom grades tailored to your unique process requirements, Gotrays delivers precision-engineered components built to last.

Ideal for industries where consistent, long-lasting heat is essential, our silicon molybdenum heaters meet strict quality standards and ensure energy-efficient performance in tough environments. With customizable options available, including different resistivity grades and element dimensions, Gotrays MoSi₂ heaters fit a wide range of industrial furnaces, boosting reliability while reducing downtime and maintenance costs.

Why Choose Gotrays MoSi₂ Heating Elements Key Advantages Over Traditional Heaters

When it comes to high temperature furnace parts, Gotrays Molybdenum Disilicide (MoSi₂) heating elements stand out. Compared to traditional heaters like Silicon Carbide (SiC) and Kanthal, our MoSi₂ heaters deliver real benefits that matter in industrial settings.

Better Oxidation Resistance

MoSi₂ heating rods handle oxidation way better, especially at temperatures up to 1800°C. Unlike SiC or Kanthal, they form a protective silica layer naturally, which keeps the element intact longer. This means less downtime and fewer replacements for you.

Energy Savings and Efficiency Gains

Because MoSi₂ is highly efficient at higher temperatures, your furnace heats up faster and maintains consistent heat with lower energy input. This translates directly into cutting your power bills without sacrificing performance. It’s a win for both your bottom line and environmental goals.

Longer Life and Durability

Gotrays MoSi₂ elements, including popular shapes like U shaped MoSi₂ elements and W type molybdenum disilicide rods, resist cracking and thermal shock better than Kanthal. That durability reduces maintenance frequency, saving labor and repair costs.

Versatile for Many Applications

Our refractory MoSi₂ heaters flexibly fit various furnace designs, making them ideal across industries like steel, ceramics, and glass. Their consistent output ensures stable processes, critical for quality control.

In short, Gotrays MoSi₂ heaters outperform traditional SiC and Kanthal elements in oxidation resistance, energy efficiency, and lifespan. If you want reliable high temperature furnace elements that keep your operation smooth and cost-effective, MoSi₂ is your go-to choice.

Technical Specifications and Grades of Gotrays Molybdenum Disilicide Heating Elements

Our Gotrays MoSi₂ heating elements come in various grades and shapes designed to fit your specific industrial furnace needs. These high temperature furnace elements deliver reliable performance up to 1800°C, making them perfect for demanding applications.

Key Specs at a Glance

| Specification | Detail |

|---|---|

| Material Grade | Standard and Custom MoSi₂ |

| Maximum Temp | Up to 1800°C |

| Resistivity | 1.2 – 2.0 ohm·cm (varies by grade) |

| Element Shapes | U-shaped, W-shaped, rods, plates |

| Diameter Range | 3mm to 12mm typical |

| Length Options | Custom lengths available |

Resistivity and Performance

Our MoSi2 heaters maintain stable resistivity across high temps, ensuring consistent heat output and energy efficiency. Depending on the grade, resistivity ranges from about 1.2 to 2.0 ohm-centimeter. This allows you to pick the right element that matches your furnace’s power and size requirements.

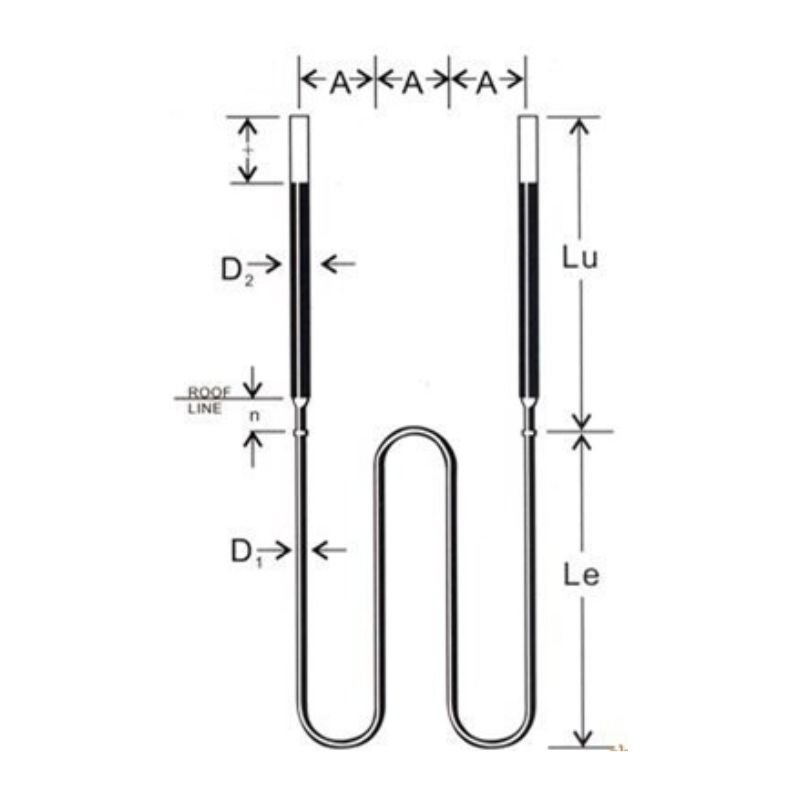

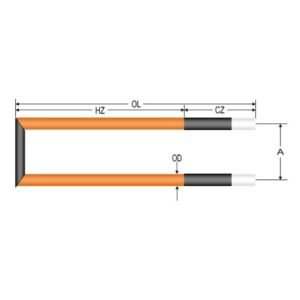

Shape and Sizing Options

- U-shaped MoSi2 elements: Most popular choice for even heat distribution.

- W type molybdenum disilicide: Ideal for faster heat-up times.

- Silicon molybdenum rods: Use in narrow spaces or custom geometries.

Use our easy sizing calculator on the website to select the perfect dimensions for your application. Just input your furnace specs, and get instant recommendations for element size and shape.

With these detailed technical specs and flexible options, Gotrays MoSi₂ heating rods offer a tailored fit for your high temperature furnace needs, helping you get the best performance and longer service life.

Applications in High Temperature Industries

Gotrays Molybdenum Disilicide (MoSi₂) heating elements are trusted across many high temperature industries in the US. Their ability to work reliably up to 1800°C makes them a top choice where durability and consistent heat are critical.

Key Industries Using MoSi₂ Heating Elements

-

Glass Manufacturing

Ideal for melting and forming, our oxidation resistant heating components handle extreme heat with minimal wear and energy loss.

-

Steel and Metal Processing

Perfect for forging, annealing, and heat treating, MoSi₂ heating rods provide long life and efficient heating for industrial furnaces.

-

Ceramics Production

Consistent temperatures ensure flawless firing and sintering processes. Our refractory MoSi₂ heaters deliver uniform heat without oxidation failure.

-

Electronics Manufacturing

Used in wafer processing and component testing, providing stable high temperatures necessary for precise operations.

-

Laboratory and R&D

Flexible shapes like U shaped MoSi₂ elements allow custom setups for research ovens, testing chambers, and pilot production heating.

Why It Matters Locally

In the US, manufacturing sectors demand reliable furnace parts to avoid downtime and costly repairs. MoSi₂ heating elements from Gotrays meet these needs with superior oxidation resistance and stable performance under tough conditions.

(Infographic: Industries Served by Gotrays MoSi₂ Heating Elements – Glass, Steel, Ceramics, Electronics, Lab R&D)

Installation Operation and Best Practices

Installing and operating Gotrays Molybdenum Disilicide (MoSi₂) heating elements right is key to getting high performance and long life from your furnace parts. Here’s a simple step-by-step guide to help you:

Pre-Installation Checks

- Inspect the element for any visible damage or cracks before installation.

- Confirm the size and shape match your furnace specs using our sizing calculator.

- Check wiring and connectors to ensure compatibility with MoSi₂ heating rods.

- Make sure the furnace chamber is clean and free of debris that could affect heating or damage the element.

Installation Steps

- Carefully place the MoSi₂ element—whether U shaped MoSi₂ elements or W type molybdenum disilicide—in position without bending or stressing the rods.

- Use proper clamps or holders designed specifically for refractory MoSi₂ heaters to secure them in place.

- Connect wiring securely, keeping clear of any sharp edges or high-temperature points that could wear insulation.

- Double-check wiring polarity and connectors before powering up.

Operation Tips

- Gradually heat up the furnace to operating temperature (up to 1800°C electric heaters capability) to avoid thermal shock.

- Monitor for any unusual noises, smells, or fluctuations in temperature which could mean wiring or element issues.

- Maintain steady power levels to maximize efficiency and prevent premature wear.

Maintenance and Troubleshooting

- Perform regular visual inspections to catch oxidation damage or surface degradation early.

- Clean the elements gently with a soft brush if dust builds up; avoid any abrasive cleaners.

- If you notice reduced heating performance, check wiring connections and furnace controls.

- Replace any worn or damaged MoSi₂ heating rods promptly to avoid impacting the whole system.

By following these installation and care practices, you’ll make sure your silicon molybdenum rods deliver reliable heat, energy savings, and outstanding oxidation resistance every time.

Gotrays Quality Assurance and Certifications

At Gotrays, quality isn’t just a goal—it’s a guarantee. Our Molybdenum Disilicide (MoSi₂) heating elements go through strict quality checks to ensure every piece meets industry and customer standards. We are ISO certified, which means our manufacturing processes follow international standards for reliability and consistency.

We back our MoSi₂ heaters with solid warranties, giving you peace of mind on performance and durability. Each heating element is made with high-purity materials, ensuring superior oxidation resistance and long service life in high temperature furnace environments.

Sustainability matters to us too. Gotrays focuses on eco-friendly manufacturing practices, reducing waste and energy consumption wherever possible. Choosing Gotrays means not only getting top-notch industrial MoSi₂ furnace parts but supporting a company committed to responsible production.

Your furnace’s performance depends on quality components—Gotrays delivers that with confidence, certified compliance, and ongoing support.

Pricing Customization and Ordering from Gotrays

At Gotrays, we know every industrial furnace has its own needs. That’s why our Molybdenum Disilicide (MoSi₂) heating elements come with flexible pricing options designed to fit your budget and project size.

Tiered Pricing

- Buy more, save more: Our volume discounts kick in as you order larger quantities of MoSi₂ heating rods or U-shaped and W-shaped elements.

- Standard and custom grades: Pricing adjusts depending on the grade of molybdenum silicide heaters you need, so you get exactly what fits your application and cost targets.

Custom Quotes

- Need a special size or unique shape? No problem.

- Contact our sales team for personalized quotes on refractory MoSi₂ heaters tailored for your furnace specs.

- We handle everything from silicon molybdenum rods to industrial MoSi₂ furnace parts — just tell us what you need.

Shipping and Delivery

- Fast and reliable shipping across the United States.

- Packaging designed to protect your high temperature furnace elements during transit.

- Clear lead times communicated upfront so you can plan your installation smoothly.

Ordering from Gotrays means you get expert support, flexible pricing, and quality MoSi₂ heating elements ready to boost your furnace efficiency. Reach out today to get your custom quote!

Frequently Asked Questions FAQ

1. What makes Gotrays Molybdenum Disilicide MoSi₂ heating elements better than traditional heaters?

Our MoSi₂ heating rods offer superior oxidation resistance and last longer in high-temperature environments compared to Kanthal or silicon carbide (SiC) heaters. This means better energy efficiency and reduced downtime for your furnace.

2. Can Gotrays MoSi₂ elements operate at temperatures up to 1800°C?

Yes, our MoSi₂ heaters are designed to withstand continuous use at temperatures up to 1800°C, making them ideal for industrial high-temp furnace applications.

3. What custom shapes and sizes are available?

We offer a variety of shapes including U shaped MoSi₂ elements and W type molybdenum disilicide rods. Custom sizing is available to fit your specific furnace design—just consult our sizing calculator or request a custom quote.

4. How long does it take to receive my order?

Typical lead times range from 2 to 4 weeks depending on the element size and customization. We work closely with you to meet urgent needs whenever possible.

5. Are Gotrays MoSi₂ heating elements compatible with all furnaces?

Our elements are designed for most high temperature furnaces in industries like glass, steel, ceramics, and electronics. For specialized applications, contact our support team for compatibility advice.

6. How do I maintain MoSi₂ heating elements for maximum life?

Regularly check wiring and terminals

Inspect for signs of oxidation or damage

Follow proper pre-installation guidelines

Avoid thermal shock by controlled heating and cooling

7. What warranty do you offer on these heating rods?

All Gotrays MoSi₂ heating elements come with a standard warranty covering manufacturing defects. We stand behind our products and quality assurance processes.

8. Can Gotrays provide technical support during installation?

Yes, our team offers hands-on guidance and troubleshooting tips to make installation and operation smooth and reliable.

9. How do MoSi₂ elements help save energy?

Their excellent heat efficiency and oxidation resistance minimize energy loss in your furnace, reducing operating costs over time.

10. Where can I find detailed product datasheets and manuals?

Visit our website to download all related datasheets, whitepapers, and product guides at any time.

If you have more questions, don’t hesitate to reach out. We’re here to help you get the best from your high temperature furnace heating components.

Related Gotrays Products and Resources

At Gotrays, we don’t just stop at Molybdenum Disilicide heating elements. We offer a range of complementary products designed to enhance your high-temperature furnace setup. Whether you need U shaped MoSi2 elements, silicon molybdenum rods, or refractory MoSi2 heaters, you’ll find reliable options built to meet your exact needs.

We also provide handy tools and materials like insulation components and mounting accessories to ensure your installation runs smoothly.

To help you make the best choice, we offer detailed datasheets and informative whitepapers available for download on our website. These resources break down specs, performance tips, and industry applications in plain language—perfect for engineers, operators, or procurement teams looking to get the most from their heating components.

Explore our product carousel online to see what pairs well with your MoSi₂ heating rods and stay updated with the latest in high temp furnace technology from Gotrays.

Ready to Upgrade Your Furnace Contact Gotrays Today

When you’re ready to boost your furnace’s performance with Gotrays Molybdenum Disilicide MoSi₂ Heating Elements, we’re here to help. Reach out via phone or email for quick answers and personalized support.

Contact options:

- Call us at 1-800-555-6789 for expert advice and fast quotes

- Email sales@gotrays.com to request a custom order or technical info

- Sign up for our newsletter to receive updates on new products, industry tips, and exclusive deals

Don’t just take our word for it—our customers across the US trust Gotrays for durable, high-temp furnace parts that last. Check out our testimonials and case studies on the website to see how we’ve helped industrial teams improve efficiency and lower energy costs.

Upgrade your furnace the smart way with Gotrays. Contact us today and experience the difference quality MoSi₂ heating rods can make.

Reviews

There are no reviews yet.