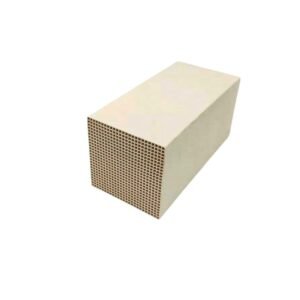

Gotrays Cordierite-Mullite Ceramic Honeycomb High-Performance Substrate for Emission Control and Thermal Applications

Engineered for unmatched thermal shock resistance and high efficiency, Gotrays Cordierite-Mullite Ceramic Honeycomb combines the low thermal expansion of cordierite with the exceptional strength of mullite. This powerful composite material is ideal for catalytic converters, regenerative thermal oxidizer (RTO) media, and high-temperature kiln supports.

Key Benefits:

- Up to 95% emission reduction

- Operates reliably at temperatures up to 1700°C

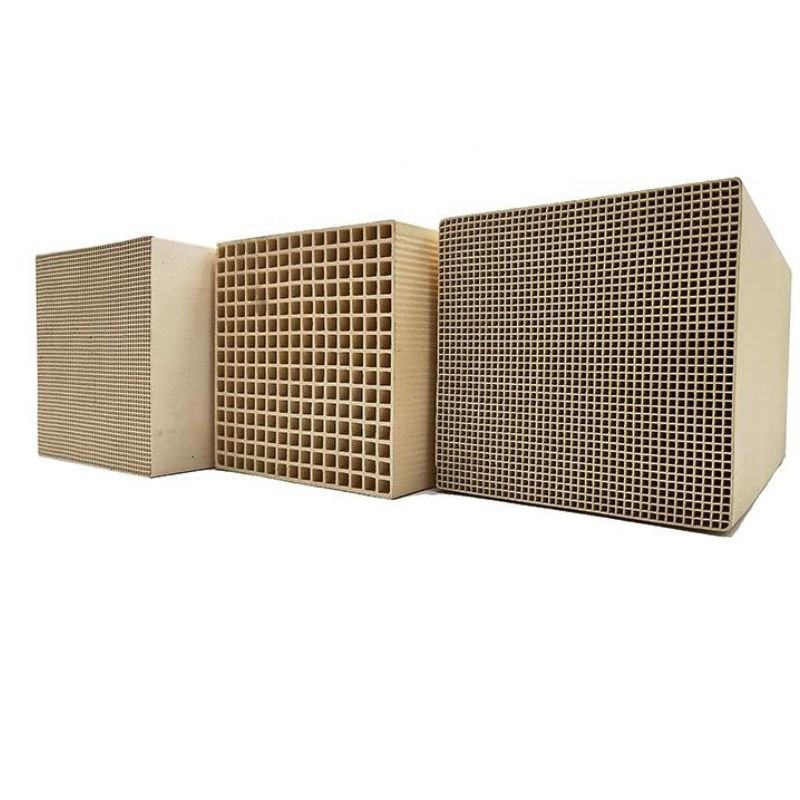

- Customizable cell density (CPSI) to fit your specific needs

Ready to boost your system’s performance?

[Request a Quote] [Download Spec Sheet PDF]

What is Gotrays Cordierite-Mullite Ceramic Honeycomb

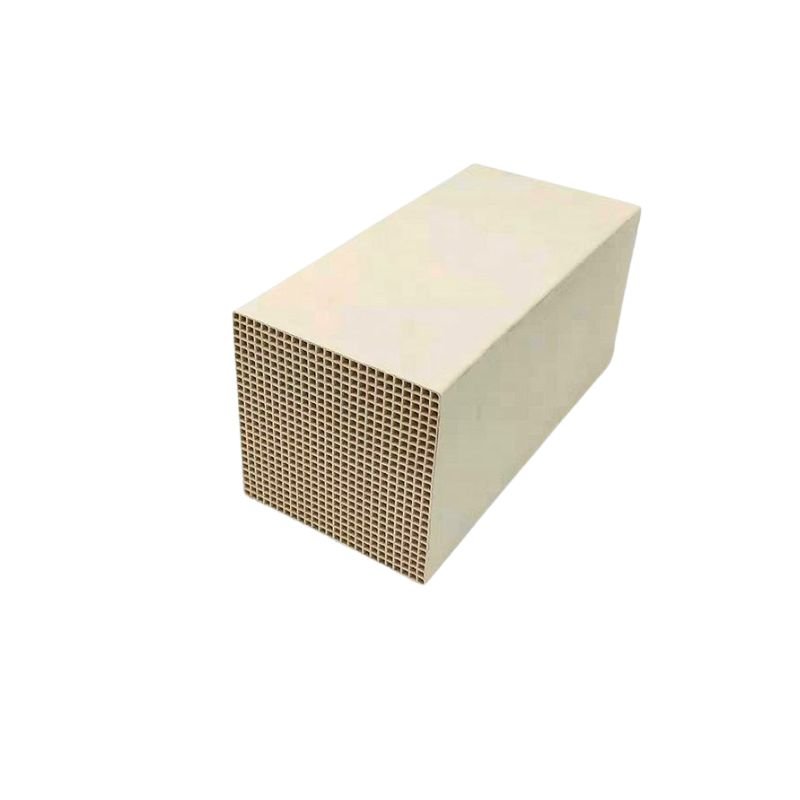

Gotrays Cordierite-Mullite Ceramic Honeycomb is a high-performance ceramic substrate designed to handle tough thermal and mechanical demands. It’s made from a carefully balanced mix of cordierite and mullite, combining cordierite’s low thermal expansion with mullite’s strong, durable matrix. This mix includes precise ratios of aluminum oxide (Al2O3) and silicon dioxide (SiO2), optimized through an advanced extrusion process.

The result is a honeycomb structure with parallel channels that maximize surface area, making it perfect for efficient catalytic converters, RTO media, and kiln furniture. This design boosts flow dynamics while maintaining excellent thermal shock resistance.

Unmatched Properties for Demanding Environments

Gotrays’ ceramic honeycomb substrate delivers:

- Thermal expansion: Less than 16×10⁻⁷/°C between 25°C and 1000°C

- Specific heat capacity: Over 1000 J/kg·K to absorb and release heat efficiently

- Porosity: 30-50% for optimal gas flow and filtration

- Density: Between 2.5 and 2.8 g/cm³, balancing strength with lightweight design

- Flexural strength: Above 100 MPa, ensuring durability in harsh conditions

Property Comparison Table

| Property | Gotrays Cordierite-Mullite | Pure Cordierite | Pure Mullite |

|---|---|---|---|

| Thermal Expansion | <16×10⁻⁷/°C | Moderate | Low |

| Specific Heat | >1000 J/kg·K | Lower | Higher |

| Porosity | 30-50% | 35-45% | 25-35% |

| Density | 2.5–2.8 g/cm³ | 2.3–2.5 g/cm³ | 3.0–3.2 g/cm³ |

| Flexural Strength | >100 MPa | 80-100 MPa | 120-140 MPa |

This composite material offers the best of both worlds—combining cordierite’s thermal stability with mullite’s strength for long-lasting, high-efficiency performance.

Customizable Specifications

Our Gotrays Cordierite-Mullite Ceramic Honeycomb comes with flexible specs to fit your exact needs. Choose from a wide range of sizes and shapes to match your application—whether automotive or industrial.

| Specification | Options |

|---|---|

| Diameter | 50 – 300 mm |

| Length | 100 – 600 mm |

| Cell Density (CPSI) | 50 – 600 |

| Wall Thickness | 2 – 6 mil |

| Shape | Round, Oval, Square |

| Material Grade | Standard, High-Purity |

Filter your choices by application to quickly find what works best for cars, trucks, or industrial systems.

Plus, all Gotrays honeycomb substrates meet strict EURO 6/VI EPA standards for emission control, ensuring top performance and compliance with U.S. regulations.

Versatile Applications Across Industries

Gotrays Cordierite-Mullite Ceramic Honeycomb fits a wide range of uses across different industries, thanks to its durability and efficiency.

Automotive

- Acts as a catalyst carrier for three-way converters

- Cuts harmful emissions like hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx)

- Meets strict US emission standards for cleaner air

Industrial

- Works as heat storage media in regenerative thermal oxidizers (RTO) and regenerative catalytic oxidizers (RCO)

- Helps destroy volatile organic compounds (VOCs) in paint and chemical manufacturing

- Improves energy efficiency while reducing pollutants

Thermal Processing

- Serves as lightweight kiln furniture for firing ferrite electronics

- Weighs 60-75% less than traditional bricks, making handling and firing faster and easier

- Provides stable, high-temperature support for consistent processing

Case Study

- Gotrays honeycomb helped a major petrochemical plant cut energy use by 20% in their RTO system

With embedded videos and application icons, we showcase how our ceramic honeycomb improves exhaust flow and boosts system performance. Whether you’re in automotive, industrial processes, or thermal firing, Gotrays honeycomb delivers reliable, efficient results every time.

Advantages and Why Choose Gotrays

When it comes to cordierite-mullite ceramic honeycomb, Gotrays stands out for a reason. Our products deliver superior performance backed by two decades of innovation and precision manufacturing. Here’s why Gotrays is the preferred choice for emission control and thermal applications in the U.S. market:

- Low backpressure improves fuel efficiency by allowing exhaust gases to flow smoothly through the honeycomb substrate.

- Creep-resistant up to 1400°C, so it maintains shape and strength in extremely high-temperature environments like RTO units and catalytic converters.

- Eco-friendly and recyclable, supporting sustainability without compromising durability.

- Low-impurity firing process ensures a clean, consistent ceramic structure that meets tough emissions standards with zero defects.

At Gotrays, we combine over 20 years of advanced ceramics expertise with precision extrusion technology. This means every cordierite mullite monolith is made for reliability and consistent quality.

Gotrays Compared to Competitors

| Feature | Gotrays Honeycomb | Typical Competitors |

|---|---|---|

| Geometric Surface Area (GSA) | Higher, more effective surface coverage | Lower GSA reduces efficiency |

| Light-off Time | Faster catalytic activation | Slower warm-up times |

| Thermal Stability | Stable up to 1400°C | May deform or degrade earlier |

| Emissions Reduction | Up to 95% reduction | Often less effective |

Choosing Gotrays means better performance, longer lifespan, and more efficient emission control tailored for the demanding conditions faced by automotive and industrial users across the U.S.

Rigorous Testing for Reliability

At Gotrays, quality is non-negotiable. Our cordierite-mullite ceramic honeycomb substrates undergo strict testing to ensure top performance and durability you can trust.

- Certified to ISO 9001 and 14001 standards for quality and environmental management

- Thermal cycling tested over 500 cycles to guarantee thermal shock resistance

- SEM analysis used to confirm phase purity and material consistency

These rigorous checks mean our ceramic honeycomb substrates deliver reliable results every time, meeting the high demands of U.S. automotive and industrial markets.

![Certification badges and lab quality control photo]

Tailored Solutions for Your Needs

At Gotrays, we know every project is different. That’s why we offer full OEM customization from prototype to production. You can choose your cell geometry, wall thickness, and coatings to fit your specific application—whether it’s for automotive emissions or industrial thermal processes.

Use our easy sizing calculator to input your flow rate and get the recommended CPSI for optimal performance. Ready to get started? Click the button below to begin your custom order and let’s build the perfect cordierite-mullite ceramic honeycomb for you.

Packaging Shipping and Support

We make sure your Gotrays Cordierite-Mullite Ceramic Honeycomb arrives safely and on time. Each unit is packed in foam-protected crates to prevent damage during transit. Our typical lead time is 4 to 6 weeks, with reliable global shipping options to serve customers across the United States and beyond.

Need help? Our 24/7 technical support team is ready to assist you with installation, product questions, and after-sales care. You’ll also get detailed installation guides to help your team get up and running smoothly.

Customer Reviews and Testimonials

Trusted by Industry Leaders

Our Gotrays Cordierite-Mullite Ceramic Honeycomb consistently exceeds expectations. Automotive OEMs report it easily meets and often surpasses EURO 6 standards for diesel filters. Customers praise its reliability and durability under tough conditions.

What they say:

- “Gotrays honeycomb outperformed every emission substrate we’ve tested—key to hitting EPA goals.”

- “We saw improved fuel efficiency and lower backpressure thanks to Gotrays ceramic monoliths.”

- “Durability is outstanding, even after thousands of hours in high-temp environments.”

Overall rating: 4.8 out of 5 stars based on industry feedback and long-term use across automotive and industrial sectors.

Ready to Optimize Your System

Take the next step to boost your performance with Gotrays Cordierite-Mullite Ceramic Honeycomb. Whether you need a custom solution or want to test the product yourself, we’ve got you covered.

- Get a Sample – Try our ceramic honeycomb substrate before you buy

- Contact an Expert – Talk to our team for tailored recommendations

- View Catalog – Explore our full range of honeycomb monolith products

Related Products

Check out our other high-performance ceramic solutions designed for your applications:

- Gotrays Mullite Honeycomb – Exceptional strength and thermal stability

- Alumina Substrates – Reliable, high-purity options for diverse needs

Optimize your emissions control and thermal processes efficiently with Gotrays today.

Engineering Excellence in Cordierite-Mullite Composition

Our Cordierite-Mullite ceramic honeycomb blends the best of both materials to deliver outstanding performance. Cordierite’s low thermal expansion means it handles rapid temperature changes without cracking—perfect for extreme thermal shock resistance. Mullite adds high strength and creep resistance, keeping the honeycomb stable even at temperatures up to 1700°C.

Together, these crystal phases balance durability and longevity, with a combined coefficient of thermal expansion (CTE) carefully engineered to stay below 16×10⁻⁷/°C across a wide temperature range. This means the honeycomb substrate expands and contracts evenly, avoiding stress and extending service life.

Honeycomb Geometry and Surface Area

The unique honeycomb structure features precise cell counts per square inch (CPSI), ranging from 50 to 600 CPSI, designed to maximize surface area for catalytic reactions or heat exchange. This translates to over 2,000 square meters of active surface area per cubic meter, boosting efficiency in applications like catalytic converters and regenerative thermal oxidizers (RTO).

The geometry also affects flow dynamics—optimized cell shapes and wall thickness help reduce backpressure and improve fuel efficiency in automotive uses.

| Property | Gotrays Cordierite-Mullite | Silicon Carbide Alternative |

|---|---|---|

| Thermal Shock Resistance | High | Moderate |

| Operating Temperature | Up to 1700°C | Up to 1400°C |

| Flexural Strength | >100 MPa | ~80 MPa |

| Density | 2.5-2.8 g/cm³ | 3.1-3.2 g/cm³ |

| Porosity | 30-50% | 15-25% |

This spec matrix shows why Gotrays’ honeycomb is a top choice for emission control and thermal applications in the United States, where durability, efficiency, and regulatory compliance are non-negotiable.

Key Applications Tailored to Industry Needs

Our Gotrays Cordierite-Mullite Ceramic Honeycomb is proven across key industries in the U.S., delivering reliable performance where it matters most.

Automotive Catalyst Substrates

- Perfect for three-way catalysts (TWC) and diesel oxidation catalysts (DOC)

- Helps cut emissions by up to 90% NOx, meeting strict EPA and EURO 6/VI standards

- Supports cleaner air with lower backpressure, boosting fuel efficiency

Industrial RTO and RCO Heat Recovery

- Ideal for regenerative thermal oxidizers (RTO) and catalytic oxidizers (RCO)

- Efficient VOC destruction protects air quality in chemical plants and manufacturing

- Case studies show significant ROI with energy savings of 20-25%

Kiln and Firing Supports

- Lightweight yet durable kiln furniture for electronics and ceramics firing

- Cuts firing times and reduces weight by up to 75% compared to traditional bricks

- Enhances throughput while maintaining product quality

For more in-depth details, check out our blog post on how ceramic honeycombs help meet EPA emissions standards.

Why Gotrays Outperforms Standard Honeycombs

When it comes to ceramic honeycomb substrates, Gotrays stands out with proven performance you can trust. Our cordierite-mullite ceramic honeycomb monolith has been lab-tested to show superior durability and efficiency compared to generic options.

Lab-Tested Performance

- Thermal Cycling: Gotrays withstands over 500 thermal shock cycles without cracking or losing strength, making it ideal for harsh environments like catalytic converters and RTO heat exchangers.

- Pressure Drop: Lower backpressure means better fuel efficiency. Gotrays honeycombs keep pressure drop minimal, outperforming standard honeycombs by up to 15%.

- Efficiency: Our optimized cell design provides higher gas surface area (GSA), improving reaction rates and emission reduction effectiveness.

Comparison Table Gotrays vs Generic Honeycombs

| Feature | Gotrays Cordierite-Mullite | Generic Cordierite or Mullite |

|---|---|---|

| Thermal Shock Resistance | Excellent (500+ cycles) | Moderate (200-300 cycles) |

| Backpressure | Low (improves fuel efficiency) | Higher (reduces engine performance) |

| Durability | >100 MPa flexural strength | 70-90 MPa |

| Cost per Kilogram | Competitive | Often cheaper but less durable |

| Efficiency in Emission Control | Up to 95% reduction | Around 80-85% |

FAQ What CPSI Works Best for Diesel vs Gasoline

- Diesel Engines: Higher cell densities (400-600 CPSI) improve filtration for diesel particulate filters, capturing more soot and particulates.

- Gasoline Engines: Lower CPSI (100-300) helps reduce backpressure while efficiently converting CO, NOx, and HC in catalytic converters.

- Custom Solutions: Gotrays tailors CPSI options to your specific needs for the best balance of performance and longevity.

Choosing Gotrays means you’re investing in a ceramic honeycomb substrate designed to deliver top-tier thermal shock resistance, low backpressure, and high emission control—perfect for the demanding needs of the U.S. automotive and industrial markets.

From Spec to Delivery Gotrays End to End Support

We know every project is different, so Gotrays offers full support from design to delivery. Whether you’re customizing cell geometry, selecting coatings, or sizing for your application, our team walks you through every step. Use our easy design consultation tool to get started and ensure your cordierite-mullite ceramic honeycomb fits your exact needs.

We also keep compliance simple. Gotrays honeycomb products meet key US and global standards like EPA and EURO 6/VI. Plus, our manufacturing focuses on sustainability with recyclable materials and low-energy firing processes, so you get performance without compromise.

Ready to tailor a ceramic honeycomb substrate for your system? Request a quote or sample today, and let’s get your project moving fast.

Real-World Results with Gotrays Honeycomb

Our Gotrays Cordierite-Mullite Ceramic Honeycomb has delivered solid results for customers across the U.S. One standout success story comes from a chemical plant that cut its RTO (Regenerative Thermal Oxidizer) energy use by 25%. That’s a major win for reducing operating costs and boosting efficiency.

We regularly hear from industry leaders who rely on our ceramic honeycomb substrates for consistent performance in tough environments. They praise the product for durability, thermal shock resistance, and emission control capabilities that exceed standards.

Check out our video testimonials from satisfied customers who’ve seen real improvements. These stories highlight how Gotrays honeycomb is helping companies meet strict emission requirements while saving energy.

What Customers Say:

- “Gotrays honeycomb helped us surpass EURO 6 standards on our diesel filters.”

- “The reduced energy use made a noticeable difference in plant operations.”

- “Reliable and high-quality – we trust Gotrays for our catalytic converters.”

Our reputation is built on these real-world successes and strong customer feedback, making Gotrays the smart choice for your emission control and thermal processing needs.

Reviews

There are no reviews yet.