Why Choose Gotrays Ceramic Fiber Board Key Benefits

Gotrays Ceramic Fiber Board stands out as a reliable choice for refractory insulation needs across industries. It offers low thermal conductivity, helping reduce energy consumption and improve efficiency in high-temperature environments. The board’s excellent thermal shock resistance ensures durability even under rapid temperature changes, minimizing maintenance costs. Its high compressive strength provides robust structural support, making it ideal for demanding applications.

Users appreciate how easy it is to cut and machine, allowing quick customization onsite without special tools. Additionally, Gotrays offers eco-friendly bio-soluble options that meet modern environmental standards by reducing airborne fiber risks. Backed by over 1,000 industrial installations nationwide, Gotrays Ceramic Fiber Board combines proven performance with innovation—trusted by professionals across the United States for consistent, long-lasting thermal protection.

Technical Specifications

Here’s a quick look at the main specs for Gotrays Ceramic Fiber Board, designed to fit your industrial needs:

| Property | Standard Grade | High-Density Grade | Bio-Soluble Grade |

|---|---|---|---|

| Max Temperature | 2300°F (1260°C) | 2550°F (1400°C) | 2100°F (1150°C) |

| Density | 8-10 pcf | 12-14 pcf | 6-8 pcf |

| Thermal Conductivity | 0.23 BTU·in/hr·ft²·°F | 0.19 BTU·in/hr·ft²·°F | 0.25 BTU·in/hr·ft²·°F |

| Thickness Options | 1/2″, 1″, 1.5″, 2″ | 1/2″, 1″, 1.5″, 2″ | 1/2″, 1″, 1.5″, 2″ |

| Standard Panel Size | 24″ x 48″ | 24″ x 48″ | 24″ x 48″ |

| Compressive Strength | 800 psi | 1200 psi | 700 psi |

Custom Dimensions and Low Shrinkage

- We offer custom sizes and shapes based on your project. Just reach out for a quote.

- Gotrays boards have low shrinkage rates, which means stability and reliability even under high heat.

With these specs, Gotrays Ceramic Fiber Board is built to deliver strong thermal resistance and dependable structural support for your toughest applications.

Applications and Use Cases

Ceramic fiber board is a go-to choice for high temperature insulation across many industries. Here’s how Gotrays ceramic fiber board fits into real-world jobs in the United States:

Industrial Furnaces and Kilns

- Used for lining and backup insulation in industrial furnaces and kilns.

- Keeps heat in, protects equipment, and cuts down on energy bills.

- Reliable as refractory insulation board for both large and small operations.

Boilers and Heaters

- Ideal for expansion joints and combustion chamber protection in boilers and heaters.

- Handles thermal cycling and resists cracking, making it a solid pick for high temperature fiber board needs.

Steel and Non-Ferrous Metal Processing

- Trusted for steel and aluminum refractory linings.

- Stands up to harsh conditions and helps maintain stable temperatures.

- Mullite fiber board options available for even tougher environments.

Aerospace and Power Generation

- Used for thermal management in aerospace and power generation.

- Lightweight, strong, and easy to shape for custom fits.

- Vacuum formed ceramic board and bio soluble fiber board variants available for specialized needs.

Gotrays ceramic fiber board is built to handle tough jobs—whether you need kiln lining material, furnace backup insulation, or high density refractory board for demanding applications.

Gotrays Ceramic Fiber Board Variants

Gotrays offers three main ceramic fiber board options to fit your specific needs: standard, high-density, and bio-soluble grades.

- Standard Grade: Great for general-purpose refractory insulation, this version balances cost and performance. It’s lightweight with good thermal shock resistance, making it ideal for furnace backup insulation and kiln lining material.

- High-Density Grade: This variant packs more mass and compressive strength. It’s perfect for heavy-duty applications like steel refractory linings and areas requiring extra durability and heat retention.

- Bio-Soluble Grade: Designed with safety and eco-friendliness in mind, this fiber board breaks down more easily if inhaled, reducing health risks during handling and installation. It’s ideal for users looking for green alternatives without sacrificing performance.

We also provide customization options tailored for U.S. businesses, including flexibility in density, thickness, and shapes. Whether you need a specific size or thickness for a unique application, Gotrays delivers quick quotes to speed up your project timeline.

This way, you get the right ceramic fiber board variant suited for your industrial furnace, boiler, or aerospace thermal management needs.

Installation Guide and Best Practices for Gotrays Ceramic Fiber Board

Installing Gotrays Ceramic Fiber Board is simple and quick. Here’s a step-by-step guide to help you get it right the first time, whether you’re lining a kiln, furnace, or handling backup insulation.

Step by Step Installation

- Measure and Mark

- Measure the area you need to cover.

- Mark the board with a straight edge and pencil for clean cuts.

- Cutting Tools

- Use a sharp utility knife for thinner boards.

- For thicker or high density refractory boards, use a hand saw or power saw.

- Always cut on a stable surface.

- Fitting and Placement

- Test fit each piece before securing.

- Leave a small gap for thermal expansion if needed.

- Adhesion Methods

- Use high temperature ceramic fiber adhesive for bonding to metal or masonry.

- For extra support, use mechanical fasteners or clips, especially on vertical surfaces.

- Curing Times

- Let adhesives cure for at least 24 hours.

- Follow manufacturer’s instructions for best results.

Safety Tips

- Wear PPE: Always use gloves, safety glasses, and a dust mask when cutting or handling ceramic fiber board.

- Low Dust Formulation: Gotrays boards are made with low dust in mind, but it’s still smart to work in a well-ventilated area.

- Clean Up: Use a vacuum or damp cloth to remove any dust after installation.

Video Tutorial

Want to see the process? Check out our quick installation video for Gotrays Ceramic Fiber Board. It covers all the basics, from cutting to curing. You’ll find the link right on our product page.

With these easy steps and safety tips, you’ll get a professional finish every time.

Frequently Asked Questions FAQs

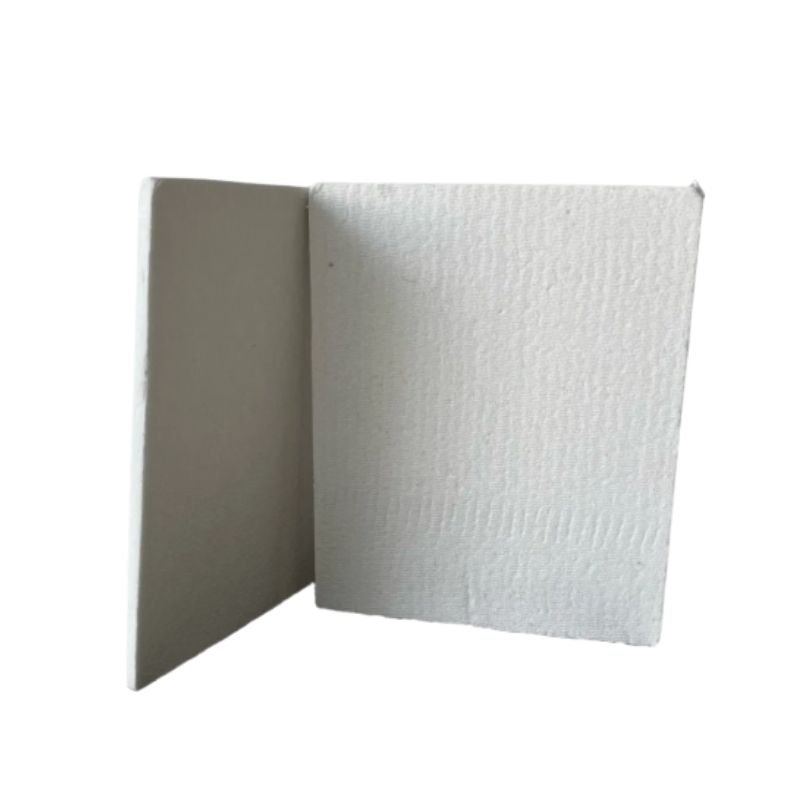

What’s the difference between ceramic fiber board and ceramic fiber blanket?

Ceramic fiber board is dense, rigid, and great for structural support and high compressive strength needs. It’s perfect for lining industrial furnaces or backup insulation where stability matters. Ceramic fiber blanket, on the other hand, is flexible, lightweight, and better for wrapping or filling irregular spaces. Both provide excellent refractory insulation but serve slightly different purposes depending on your project.

How easy is it to machine Gotrays ceramic fiber board?

Gotrays ceramic fiber board is designed for easy cutting and shaping. You can use common tools like saws, drills, and routers without much hassle. Its low dust formulation also means less mess while machining, making it safer and more convenient on the job site.

What are the shipping options for local areas?

We offer fast and reliable shipping across the United States. Local orders often qualify for next-day or two-day delivery, thanks to our efficient logistics network. We also provide tracking info so you can monitor your shipment every step of the way.

Are there bulk pricing options for large orders?

Yes, Gotrays offers competitive bulk pricing for large volume buys. Whether you need ceramic fiber boards for an industrial facility or multiple projects, we can provide discounts and flexible payment terms. Contact us for a quick quote tailored to your needs.

Related Gotrays Products

Looking to complement your Gotrays Ceramic Fiber Board? Our range of related products helps you complete your insulation projects with ease and confidence.

-

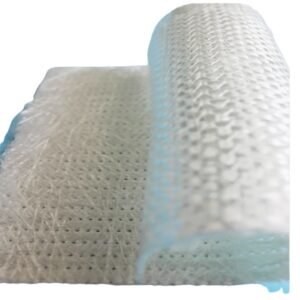

Ceramic Fiber Blankets

Soft and flexible, these blankets offer excellent thermal shock resistance and low thermal conductivity. Perfect for lining irregular shapes or adding extra insulation layers.

[Shop Now] -

Ceramic Fiber Modules

Pre-formed insulation blocks designed for quick installation and reliable performance in industrial furnaces and kilns. High density and durable for tough thermal environments.

[Shop Now] -

Ceramic Fiber Adhesives

Specially formulated to bond fiber boards, blankets, and modules securely. Our adhesives cure quickly and maintain strong bonds at high temperatures with minimal smoke and odor.

[Shop Now]

Each product is designed to work seamlessly with Gotrays Ceramic Fiber Board, making your insulation job smoother and more efficient. Browse now to find the right materials for your next project.

Reviews

There are no reviews yet.