What Are Boron Nitride Machinable Ceramic Parts

Boron Nitride (BN) machinable ceramic parts are precision components made primarily from hexagonal boron nitride (hBN). This unique material structure, often referred to as “white graphite,” combines excellent lubricity and thermal stability with high chemical resistance. These parts are typically produced using a hot-pressing process, where powdered hBN is consolidated under high temperature and pressure to form dense, durable ceramics.

There are several grades of BN machinable ceramics tailored for specific industrial needs. Pure hBN offers outstanding thermal conductivity and electrical insulation, making it ideal for high-purity applications. Meanwhile, composite grades like ZSBN (Zirconium-Doped Boron Nitride) and TPBN (Titanium-Phased Boron Nitride) enhance mechanical strength and wear resistance, extending part life in demanding environments.

For U.S.-based clients, local sourcing and machining ensure faster turnaround times and reliable supply chains. Gotrays leverages domestic facilities to provide high-precision BN parts with quick delivery, helping U.S. manufacturers reduce lead times and improve operational efficiency.

Exceptional Properties of Gotrays BN Machinable Ceramics

Gotrays Boron Nitride (BN) machinable ceramics stand out for their unique mix of thermal, mechanical, electrical, and chemical properties — making them a top choice in demanding US industries.

Thermal Properties

- High thermal conductivity: Gotrays BN parts quickly transfer heat, helping prevent hotspots and improve process efficiency.

- Shock resistance: These ceramics handle rapid temperature changes without cracking or losing integrity, ideal for harsh thermal cycles.

Mechanical Properties

- Easy machinability: Thanks to the hexagonal boron nitride (hBN) structure, Gotrays BN components machine cleanly with dry CNC diamond tooling, saving time and cost.

- Low coefficient of thermal expansion: This keeps parts dimensionally stable under heat, reducing the risk of warping or distortion.

Electrical and Chemical Properties

- Excellent electrical insulation: Gotrays BN parts provide reliable non-conductive barriers, perfect for high-voltage or sensitive electronic applications.

- Non-wetting surface: Resistant to molten metals and many chemicals, these ceramics prevent sticking and corrosion, improving part lifespan.

Properties Chart Overview

Here’s your table in a clean, publication-ready format:

| Property | Gotrays BN | Competitor Average | Advantage |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 60–90 | 40–70 | Up to 30% better |

| Thermal Shock Resistance | High | Moderate | Higher durability |

| Machinability | Excellent | Good | Faster production |

| Coefficient of Expansion (ppm/°C) | ~2.5 | 4–6 | Better dimensional stability |

| Electrical Resistivity (Ω·cm) | >10¹³ | 10¹¹–10¹³ | Superior insulation performance |

Gotrays BN machinable ceramics deliver consistently high performance for US customers needing reliable, durable, and efficient components.

Key Applications and Benefits in Demanding Industries

Boron Nitride machinable ceramic parts from Gotrays serve critical roles across several demanding industries in the US, thanks to their unique properties.

Foundry Sector Molten Metal Resistance

Our BN parts excel in the foundry industry where extreme heat and molten metals challenge equipment durability. Gotrays BN nozzles and fixtures resist wear and chemical attack, handling temperatures that would degrade metal or other ceramics.

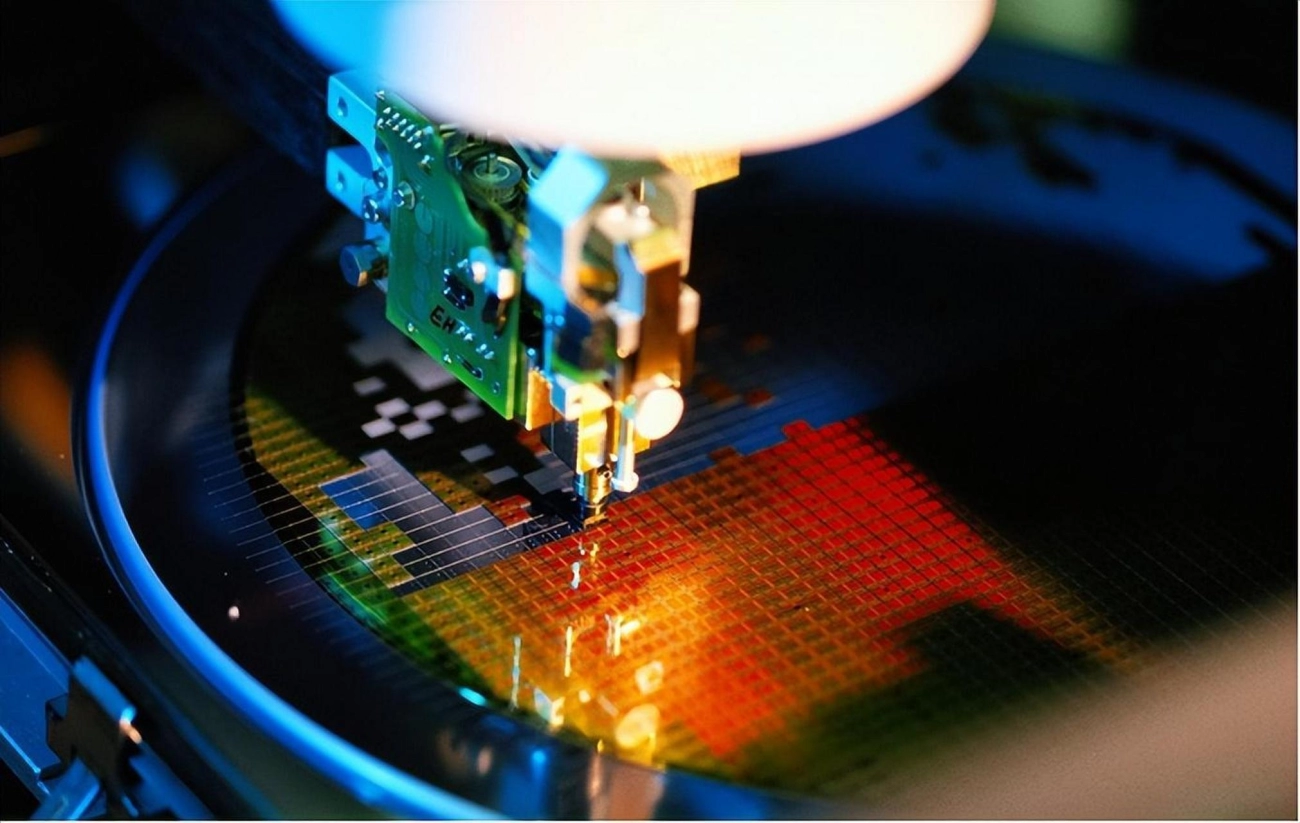

Semiconductor Sector Heat Dissipation

In semiconductor manufacturing, managing heat is crucial. Boron Nitride’s high thermal conductivity and electrical insulation make Gotrays BN components ideal for heat sinks and thermal management parts, improving device performance and longevity.

Aerospace Sector Lightweight Insulators

Weight and thermal stability are key in aerospace. Gotrays BN insulators offer lightweight solutions with excellent thermal shock resistance, protecting sensitive components from extreme temperature swings without the added bulk.

Case Study Gotrays BN Nozzles Reduce Downtime 30 Percent

A major US foundry using Gotrays BN nozzles in continuous casting reported a 30% reduction in downtime. The nozzles’ resistance to thermal shock and molten metal wear extended operating life, reducing maintenance frequency and boosting productivity.

Quantifiable ROI Benefits in High-Temp Environments

- Extends part life by up to 40% under extreme heat

- Lowers maintenance costs due to superior wear resistance

- Reduces unexpected downtime with reliable thermal shock resistance

- Improves process efficiency through stable performance at high temperatures

Gotrays Boron Nitride machinable ceramic parts deliver clear value, making them a smart investment for US companies facing tough operating conditions.

Gotrays Precision Machining and Customization Capabilities

At Gotrays, we specialize in precision machining of boron nitride machinable ceramic parts using advanced dry CNC diamond tooling. This process ensures clean cuts, tight tolerances, and excellent surface finishes, making our parts ready for demanding applications straight out of the machine.

We offer a wide range of customization options to meet your exact needs, including:

- Custom sizes and shapes tailored to your project

- Tolerances as tight as ±0.0005 inches for precision fit

- SiC-BN hybrid materials for enhanced strength and wear resistance

Quality is key to us, so every part goes through strict controls and testing protocols. We monitor thermal, mechanical, and dimensional properties to guarantee consistent performance. Plus, our boron nitride parts come with clear shelf life guidelines to keep your inventory in top shape.

Ready to get started? Upload your CAD files today, and our engineers will quickly check feasibility and provide expert guidance to bring your project to life.

Why Gotrays is Your Trusted BN Parts Partner

At Gotrays, we bring decades of experience working with boron nitride machinable ceramic parts, delivering trusted solutions across the United States. Our deep knowledge of hexagonal boron nitride (hBN) and hot-pressed BN ceramics means you get high-quality, reliable products every time.

We hold strict ISO certifications that ensure our manufacturing and quality control meet the highest standards. When you choose Gotrays, you’re picking a partner committed to precision and consistency.

Sustainability is a priority for us. Gotrays BN parts meet RoHS standards and comply with eco-friendly practices, so you can trust our products are safe and environmentally responsible. This helps your operations stay compliant without compromising quality.

Don’t just take our word for it—our clients in foundry, semiconductor, and aerospace industries consistently praise the durability, performance, and fast delivery of Gotrays BN parts. Check out our client testimonials to see why we’re the trusted BN parts partner for US customers.

Frequently Asked Questions About Boron Nitride Machinable Parts

Here are some common questions we get about Boron Nitride machinable ceramic parts, especially for customers in the U.S. and industries needing precision performance.

Can Boron Nitride parts handle vacuum brazing?

Yes, hexagonal Boron Nitride (hBN) machinable ceramics withstand vacuum brazing processes well. Their chemical stability and low outgassing make them ideal for high-temp vacuum environments.

What grades of BN parts do you offer?

We provide pure hBN and composite grades like ZSBN and TPBN. Each has different thermal, mechanical, and machinability profiles to fit your exact application.

Are Gotrays BN parts customizable?

Absolutely. We do custom sizes, tight tolerances, and even hybrid parts like SiC-BN ceramics for specialized heat resistance or wear needs.

How fast is U.S.-based machining and shipping?

Since our machining happens locally in the U.S., we offer faster lead times compared to overseas suppliers, ensuring your projects keep moving without long delays.

What industries use BN machinable ceramics the most?

Foundry, semiconductor, and aerospace sectors rely heavily on BN parts for molten metal resistance, heat dissipation, and lightweight electrical insulation.

What testing ensures quality?

Each part is tested for dimensional accuracy, thermal conductivity, and durability under real-world conditions. We follow strict protocols to meet ISO standards.

Can BN parts resist molten metals?

Yes, that’s a core benefit of BN parts. They resist wetting and corrosion from molten metals, making them perfect for nozzles, crucibles, and break rings.

How does machinability compare to other ceramics?

Machinable BN ceramics are easier to shape with dry CNC diamond tooling, which reduces production time and costs without sacrificing performance.

If you have more questions about Boron Nitride machinable parts or want a feasibility check, upload your CAD file and let’s get started.

Explore Related Gotrays Products

At Gotrays, we offer a wide range of Boron Nitride (BN) products to complement our machinable ceramic parts. Whether you need raw BN blanks for custom projects or protective BN coatings, we’ve got you covered. Our BN crucibles are designed for high-temperature applications and ensure durability in demanding environments.

Here’s a quick look at what we provide:

- BN Blanks – Ready-to-machine hexagonal Boron Nitride pieces for your specific designs

- BN Coatings – High-performance layers to protect components against wear and chemical exposure

- BN Crucibles – Reliable, heat-resistant containers perfect for molten metal handling

All our products are backed by strict quality control and made with US-sourced materials for consistent performance and faster delivery times.

Stay Connected

Sign up for our newsletter to get the latest updates on new products, machining tips, and industry news.

For any questions or orders, check our contact page or find a local Gotrays warehouse near you for quick service and support.

Reviews

There are no reviews yet.