What Are Alumina Ceramic Nozzles

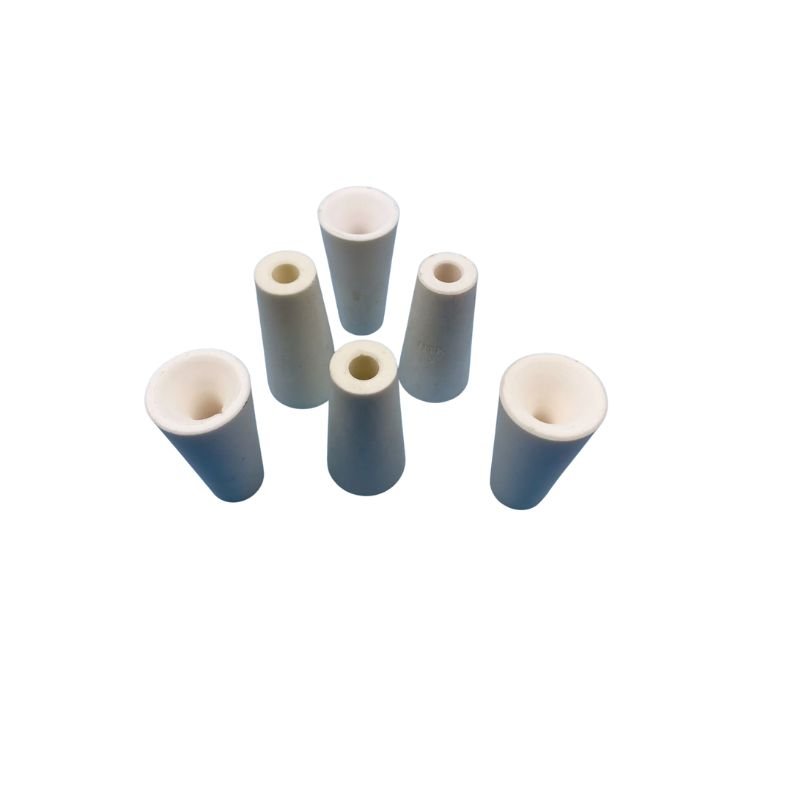

Alumina ceramic nozzles are precision-engineered components made primarily from aluminum oxide (Al2O3), a high-purity ceramic material known for its exceptional hardness and durability. These nozzles are formed through a process that involves powder pressing followed by high-temperature sintering, resulting in a dense, wear-resistant structure ideal for demanding industrial applications.

Over time, alumina ceramic nozzles have evolved from basic ceramic tips into sophisticated parts tailored for specific tasks like TIG welding, abrasive blasting, and industrial spraying. Their unmatched resistance to heat, abrasion, and chemical corrosion has made them indispensable in sectors where reliability and precision are critical.

Gotrays sets itself apart by delivering alumina ceramic nozzles with superior quality control and precision manufacturing. Using advanced ISO-certified testing, each nozzle guarantees consistent performance, tighter tolerances, and longer service life compared to competitors. This ensures customers benefit from reduced downtime and enhanced operational efficiency.

Key Features of Gotrays Alumina Ceramic Nozzles

Gotrays alumina ceramic nozzles stand out because of their superior durability and design. Made from high-purity alumina oxide, these nozzles offer exceptional wear and abrasion resistance. In typical industrial use, they last 3 to 5 times longer than standard ceramic nozzles, meaning fewer replacements and less downtime.

These nozzles handle high temperatures and thermal shocks without cracking or deforming, making them reliable even in the most demanding applications. Whether it’s TIG welding or abrasive blasting, they maintain their shape and performance under intense heat cycles.

Corrosion and chemical resistance are other big advantages. Gotrays nozzles can handle harsh media — from welding gases to acidic blasting compounds — without degrading or losing efficiency. This makes them ideal for tough work environments across manufacturing and metalworking.

On top of that, Gotrays invests in precision engineering. Their nozzles come in a variety of customizable geometries to fit different torch types, thread sizes, and application needs. This ensures a perfect fit every time and improved performance in tasks like industrial spraying, waterjet cutting, or sandblasting.

In short, Gotrays alumina ceramic nozzles combine toughness, resistance, and precision to deliver reliable results for professionals who don’t want to settle for less.

Applications and Use Cases

Gotrays alumina ceramic nozzles fit right in with a range of tough industrial jobs where durability and precision matter.

-

TIG and GTA welding torch compatibility

Our nozzles work perfectly with TIG and GTA welding torches, offering strong wear resistance and stable performance. This means cleaner, more accurate welds and longer-lasting tips for your welding gear.

-

Sandblasting and abrasive blasting advantages

Using Gotrays wear-resistant ceramic blasting nozzles in sandblasting delivers better abrasion resistance and less downtime. They stand up to tough blasting media, improving your ROI by cutting replacement costs and keeping projects moving.

-

Industrial spraying and atomization efficiency

In spraying and atomizing applications, our precision alumina jet nozzles ensure even distribution and efficient flow. This boosts your process reliability whether you’re coating, cooling, or applying chemicals.

-

Waterjet cutting and precision manufacturing stability

For high-pressure waterjet cutting, Gotrays ceramic alumina nozzles provide stable jets that hold their shape longer. This helps maintain accuracy in manufacturing tasks while resisting corrosion and wear, even under constant use.

Each of these use cases benefits from Gotrays’ quality, making our alumina oxide welding tips and blasting nozzles a solid choice for American industries needing reliable, long-lasting ceramic components.

Gotrays vs Competitors Why Our Nozzles Excel

When you compare Gotrays alumina ceramic nozzles with other brands, the difference is clear. Our nozzles deliver longer lifespan and better cost savings, helping you cut down on frequent replacements and downtime. This means you spend less while keeping your operations running smoothly.

We back our quality with ISO-certified testing to make sure each ceramic alumina nozzle meets the highest standards for wear resistance and durability. Our team’s expertise in precision engineering ensures each nozzle performs consistently, whether it’s for industrial ceramic torch nozzles or abrasion-resistant spray nozzles.

Customers across the US have shared how switching to Gotrays nozzles improved their workflows:

- Extended torch life in TIG and GTA welding

- Reduced wear in sandblasting applications, boosting ROI

- Stable, precise spray patterns in industrial spraying and cutting

These real-world results prove why Gotrays stands out. If you want a high-purity Al2O3 nozzle that lasts and performs, our products deliver both quality and operational benefits you can count on.

Product Specifications and Customization Options

At Gotrays, our alumina ceramic nozzles come in a range of purity grades, from standard high-purity Al2O3 to ultra-high-purity options, ensuring you get the right balance of performance and cost for your needs. Whether you need a ceramic alumina nozzle for welding or blasting, we offer various dimensions and thread types to fit most industry-standard tools.

To help you pick the right size, we provide an easy-to-use sizing guide with clear charts and interactive tools—perfect for matching your torch, spray gun, or machine specs without the guesswork.

If you have unique requirements, our team supports custom OEM prototyping to develop nozzles tailored to your exact specifications. We handle small runs and large volume orders alike, delivering precision alumina jet nozzles that meet your production goals and keep your operations running smoothly.

Choose Gotrays for flexible, reliable, and fully customizable alumina ceramic nozzles designed with the U.S. market in mind.

Installation Maintenance and Best Practices

Step by Step Torch Integration and Cleaning

Installing Gotrays alumina ceramic nozzles is straightforward:

- Turn off your torch and let it cool before handling.

- Remove the old nozzle by unscrewing it carefully to avoid damage.

- Inspect the torch head for debris or wear before putting on the new nozzle.

- Screw on the Gotrays alumina ceramic nozzle firmly but don’t overtighten—it’s precision-made to fit right.

- Test the torch briefly to ensure proper gas flow and arc stability.

For cleaning, use a soft brush or compressed air to remove dust and residue. Avoid harsh chemicals or abrasive tools that can wear down the ceramic surface.

Troubleshooting Common Issues and Fixes

If you notice spattered welds, inconsistent arcs, or reduced gas flow, check:

- Nozzle blockages —clean with compressed air or replace if heavily worn.

- Loose fittings —tighten connections without forcing threads.

- Cracks or chips —replace the nozzle immediately to maintain performance.

Regular inspection helps catch these issues early and keeps your welding or blasting efficient.

Sustainability and Recyclable End of Life

Gotrays alumina ceramic nozzles are designed for long-term use, cutting down waste and replacement costs. At end of life:

- These nozzles can be recycled through specialized ceramic recycling programs available in several states.

- Proper disposal supports your company’s environmental goals and reduces landfill waste.

We encourage customers to contact our support team for guidance on recycling and disposal options that fit local regulations.

Frequently Asked Questions

What’s the difference between alumina ceramic nozzles and zirconia nozzles

Alumina ceramic nozzles are made from high-purity Al2O3, known for their excellent wear resistance and ability to handle high temperatures. They’re great for applications needing durability and thermal stability. Zirconia nozzles, on the other hand, offer better toughness and fracture resistance but usually cost more and don’t handle abrasion quite as well. For most industrial uses like welding, sandblasting, and spraying, alumina nozzles provide a reliable, cost-effective option.

Where does Gotrays ship from and what regions do you cover

We ship alumina ceramic nozzles primarily across the United States with fast delivery to major industrial hubs. For international customers, we provide shipping options based on volume and destination—feel free to reach out to discuss your location and shipping needs.

Can Gotrays customize alumina ceramic nozzles

Yes, we offer custom sizes, thread types, and purity grades to fit your specific equipment and process requirements. Talk to our team about OEM prototyping and volume production runs tailored to your business.

How long can I expect these nozzles to last

Gotrays alumina nozzles typically last 2 to 3 times longer than standard ceramic blasting nozzles, depending on the application. Regular maintenance and proper installation extend their life even further.

Are Gotrays nozzles recyclable or eco-friendly

Our alumina ceramic nozzles are designed with sustainability in mind. While ceramics themselves aren’t biodegradable, they can often be recycled or safely disposed of at the end of their lifespan, reducing environmental impact compared to metal alternatives.

If you have more questions, contact our support team—we’re here to help you find the right alumina ceramic nozzle for your needs.

Shop Gotrays Alumina Ceramic Nozzles Today

Ready to upgrade your welding, blasting, or industrial spraying setup? Gotrays offers a full range of alumina ceramic nozzles tailored to fit your needs and budget.

Pricing Tiers

We provide competitive pricing with clear tiers based on purity, size, and customization options. Whether you’re buying bulk for production runs or a single precision alumina jet nozzle, you’ll find a price that works for you.

Stock Status

Most popular sizes and types, including high-purity Al2O3 nozzles and abrasion-resistant spray nozzles, are in stock and ready to ship across the US. Check real-time inventory on our website to avoid downtime.

Bundles

Save more with bundle deals designed for TIG torch users, sandblasting pros, or waterjet cutting operators. Bundles include multiple nozzles plus accessories for a complete package.

Get a Quote and Access Full Catalog

Have specific needs? Request a quick custom quote or ask about OEM prototyping and volume runs. Explore our full catalog online and find precision alumina or ceramic alumina nozzles that fit your exact specs.

Don’t wait—shop Gotrays alumina ceramic nozzles today and experience quality you can rely on.

Reviews

There are no reviews yet.