Product Overview Material and Spiral Design Benefits Key Features and Applications

The Single-Spiral Silicon Carbide Heating Element is a high-performance heating solution designed for demanding industrial environments. Made from Reaction-Bonded Silicon Carbide, this SC type SiC heating element offers exceptional durability and thermal stability, making it ideal for applications requiring consistent heat up to 1600°C.

The unique single-spiral design improves heat distribution and overall efficiency. This spiral configuration ensures even temperature control and faster heating cycles compared to traditional rod heaters. The innovative shape reduces hot spots, extends the element’s lifespan, and supports reliable operation in high-temperature furnaces and kilns.

Key features include:

- Superior resistance to thermal shock and corrosion

- Stable electrical properties at elevated temperatures

- Compatibility with U-shaped and SG type silicon carbide rod configurations

- Versatility for use in ceramics, metallurgy, glass processing, and semiconductor industries

Applications range from industrial kiln heating systems to custom single-spiral SiC elements tailored for specialized thermal processes. Whether it’s a small-scale lab furnace or large industrial equipment, this heater delivers consistent performance and energy efficiency.

Explore how the single spiral silicon carbide heating element can enhance your heating solutions while reducing downtime and maintenance.

Technical Specifications Single-Spiral Silicon Carbide Heating Element

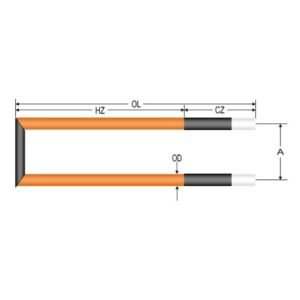

Our Single Spiral SiC Rod Heater is designed with precise technical specifications to meet the needs of high-temperature industrial applications. The physical dimensions typically range from 12 to 36 inches in length, with a diameter customized to fit your specific furnace or kiln setup.

Physical Dimensions and Electrical Ratings

- Length: 12 to 36 inches (custom sizes available)

- Diameter: 10 to 20 mm depending on model

- Voltage: 120V to 480V options to match standard US power supplies

- Wattage: From 250W up to 3000W based on size and resistance

- Operating Temperature: Up to 1600°C, ideal for demanding environments

These ratings ensure compatibility with most industrial kiln and furnace configurations found across manufacturing plants in the US.

Material Composition and Compliance

Our heating elements use Reaction-Bonded Silicon Carbide (RB-SiC) material, known for excellent thermal shock resistance and high durability at elevated temperatures. The SC Type SiC Heating Element and SG Type Silicon Carbide Rod components both meet the latest industry standards, including compliance with ASTM and RoHS regulations, ensuring safety and environmental responsibility.

By sticking to high-grade material standards and strict manufacturing controls, these Single Spiral SiC Heating Elements deliver consistent, reliable performance in industrial settings such as ceramics, metallurgy, glass, and semiconductor processing.

Benefits and Advantages of Single-Spiral Silicon Carbide Heating Element

Using a single-spiral Silicon Carbide heating element brings several clear benefits, especially for industrial users in the U.S. looking for reliable and efficient heating solutions.

Energy Savings and Maintenance Reduction

- High Efficiency: The SC type SiC heating element operates at high temperatures up to 1600°C with excellent heat transfer, which means faster heating cycles and less energy wasted.

- Long Lifespan: Thanks to its reaction-bonded silicon carbide construction, wear and tear are minimal. This reduces the frequency of replacements and lowers maintenance costs.

- Stable Performance: The single spiral design helps maintain consistent heat distribution, preventing hot spots that could damage your materials or the element itself.

- Less Downtime: Fewer element failures mean your industrial processes run smoothly without costly interruptions.

Comparison with Other Heating Elements

Compared to traditional metal heaters or other ceramic elements, the single spiral SiC rod heater stands out because:

- Higher Temperature Resistance: It handles extreme temps better than nichrome or molybdenum elements.

- Corrosion and Oxidation Resistance: It lasts longer in harsh kiln atmospheres, common in ceramics and metallurgy.

- Better Mechanical Strength: The U-shaped or alpha rod silicon carbide heaters resist cracking and thermal shock better than many alternatives.

- Lower Energy Costs: Because it heats more efficiently, you save on electricity bills over time.

If energy efficiency, durability, and reduced maintenance matter to you, the single-spiral SiC heating element is a smart choice for your industrial heating needs.

Applications Industrial Use Cases in Ceramics Metallurgy Glass and Semiconductors Case Study Highlights

The Single-spiral Silicon Carbide Heating Element shines in tough industrial settings where reliable high-temperature performance is a must. Many U.S. manufacturers trust these SC Type SiC Heating Elements for processes in ceramics, metallurgy, glass, and semiconductor production.

Industrial Use Cases

- Ceramics: Ideal for kiln heating thanks to its ability to handle rapid temperature changes and maintain even heat distribution. The Single Spiral SiC Rod Heater keeps firing cycles efficient and consistent.

- Metallurgy: Used in heat treatment furnaces where strong, stable heating is crucial. The Reaction-Bonded Silicon Carbide Heater resists chemical attacks and thermal shock, making it perfect for melting or forging processes.

- Glass Industry: Operates smoothly in glass melting and forming furnaces at temperatures up to 1600°C. The High-Temperature Spiral Furnace Element ensures stable thermal output to reduce defects.

- Semiconductors: The precision heating from the SG Type Silicon Carbide Rod supports wafer processing and other delicate steps where temperature control is critical.

Case Study Highlights

A U.S.-based ceramics company upgraded to the Industrial Kiln SiC Spiral Heater and saw:

- Reduced energy consumption by 15%

- Longer heater lifespan compared to traditional metal elements

- Fewer maintenance shutdowns

Meanwhile, a glass manufacturer reported improved product quality after switching to the U-Shaped SiC Heating Element, attributing better heat uniformity and element durability to the Silicon Carbide design.

Overall, the Custom Single-Spiral SiC Element proves adaptable across sectors needing reliable, high-temp heating solutions. These heaters stand out for their efficiency and durability in demanding industrial processes throughout the United States.

Installation and Maintenance Guide

Mounting Wiring and Atmosphere Considerations

Installing your Single-spiral Silicon Carbide Heating Element is straightforward but requires care. Mount the SC Type SiC heating element securely using appropriate supports to avoid stress on the rod. Make sure the element is correctly positioned inside your furnace or kiln to allow even heating.

For wiring, use high-temperature-resistant leads rated for the element’s voltage and current. Keep wiring connections tight and insulated to avoid shorts or power loss. Always follow local electrical codes and safety standards.

Atmosphere plays a big role in the lifespan of your Single Spiral SiC Rod Heater. These elements perform best in neutral or oxidizing environments. Avoid pure reducing atmospheres as they can degrade the Reaction-Bonded Silicon Carbide heater quickly.

Troubleshooting and FAQ

Here are quick tips if you notice issues with your Industrial Kiln SiC Spiral Heater:

- Element not heating properly? Check for loose wiring or damaged connections first.

- Uneven heating? Inspect mounting; uneven tension can cause hot spots.

- Short circuits? Look for contamination or damage on the SiC rod surface.

- Element lifetime too short? Verify atmosphere conditions and operating temperatures. Exceeding 1600°C can reduce lifespan.

If you encounter other problems, reach out to our support team. We offer expert advice to keep your high-temperature spiral furnace element working efficiently.

Customization Options Size Resistance and Accessories Selection Configurators and Ordering Process

When it comes to single-spiral Silicon Carbide heating elements, customization is key to meeting your specific needs. You can choose from a range of sizes and resistance values to match your equipment and temperature requirements precisely. Whether you need a compact SC type SiC heating element or a larger industrial kiln SiC spiral heater, there’s flexibility in length, diameter, and spiral pitch.

We also offer various accessories like mounting clamps, protective sheaths, and terminal connectors to make installation straightforward and secure. If you’re dealing with particular atmospheres or voltage setups, these extras help optimize performance and durability.

To make the ordering process smooth, we provide easy-to-use configurators on our website. Just enter your specs—such as element size, resistance, and operating conditions—and the tool will recommend the best single spiral SiC rod heater variation for your application. This ensures you get exactly what you need without second-guessing.

Our team is ready to assist with any custom requests or questions, helping you pick the right reaction-bonded silicon carbide heater every time. This personalized approach sets us apart, especially for customers in the US who rely on precision and fast turnaround.

Related Products and Resources

Looking for alternatives or additional heating solutions? Alongside the Single-spiral Silicon Carbide Heating Element, we offer a range of industrial heaters designed to meet different temperature needs and environments. These include:

- U-Shaped SiC Heating Elements for compact spaces and uniform heat distribution

- Reaction-Bonded Silicon Carbide Heaters ideal for harsh chemical atmospheres

- SG Type Silicon Carbide Rods with enhanced durability for long service life

- Alpha Rod Silicon Carbide Heaters for higher temperature precision

We also provide downloadable resources such as installation manuals, product datasheets, and maintenance guides to help you get the best out of your SiC heating elements. These are designed to support U.S. industries ranging from ceramics to semiconductor manufacturing.

For any questions or technical support, our customer service team is ready to assist. Whether you need advice on the right product, installation help, or troubleshooting tips, contact us anytime via phone, email, or live chat. We’re committed to ensuring your operations run smoothly and efficiently with our reliable heating technology.

Customer Support and Call to Action Testimonials Case Studies Pricing and Availability

We stand behind every single-spiral silicon carbide heating element we deliver. Our US-based customer support team is ready to help with technical questions, installation advice, and troubleshooting. Whether you need guidance on the SC type SiC heating element or custom single-spiral SiC element options, we’re just a call or email away.

Don’t just take our word for it—many customers in ceramics, metallurgy, and semiconductor industries have shared how our reaction-bonded silicon carbide heaters improved their process efficiency and lowered maintenance time. Check out our case studies to see real results in industrial kiln SiC spiral heater applications.

Pricing and availability are competitive and transparent. We offer flexible order sizes with no hidden fees, and most standard models ship promptly to meet tight deadlines. If you need a high-temperature spiral furnace element or a custom size, get in touch to discuss your requirements and get a quote fast.

Ready to upgrade your heating system with a reliable SG type silicon carbide rod? Contact us today to find the perfect single spiral SiC rod heater for your operation.

Reviews

There are no reviews yet.