Why Choose Gotrays Sillimanite Ceramic Blocks Key Features Explained

When selecting refractory solutions, Gotrays Sillimanite Ceramic Blocks stand out for their unmatched durability and performance. Engineered to excel in extreme environments, these blocks provide exceptional thermal shock resistance, meaning they withstand rapid temperature changes without cracking or degrading. This feature is critical in high-temperature kiln furniture and furnace linings where fluctuating heat can cause common materials to fail.

Gotrays blocks also offer robust corrosion protection against slag, a frequent problem in metallurgical and glass industries. Slag-resistant properties ensure longer service life and reduced maintenance, helping plants maximize uptime and lower replacement costs.

Another vital advantage is the low thermal expansion rate, which minimizes structural stress during heating and cooling cycles. This characteristic directly improves longevity and stability in demanding settings, such as blast furnace throat bricks and high-alumina ceramic block applications.

Choosing Gotrays means choosing a reliable, high-performance Sillimanite refractory brick tailored to meet the rigorous demands of modern manufacturing. These key features combined provide proven value for industries requiring tough, long-lasting ceramic refractories. Contact Gotrays today to discover how our blocks can enhance your operations.

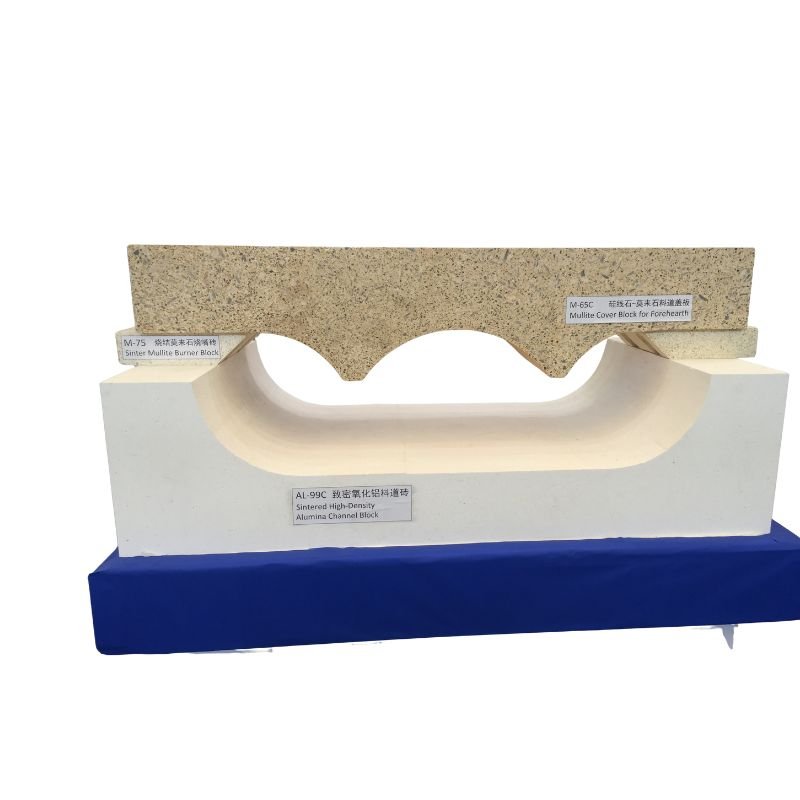

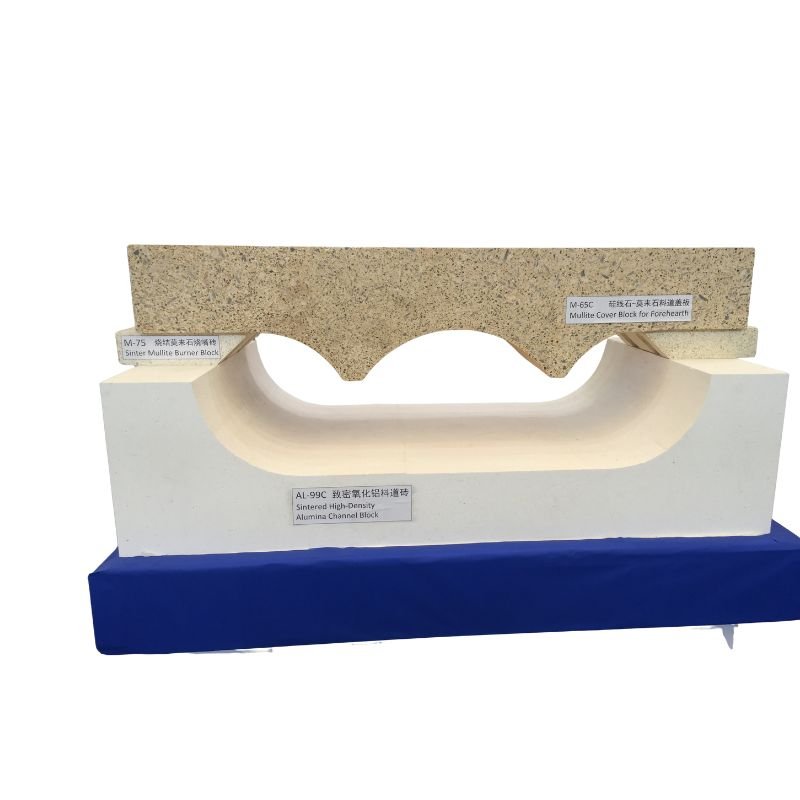

Technical Specifications Data Driven Performance for Refractory Pros

Gotrays Sillimanite Ceramic Blocks are designed with performance in mind, making them a top choice for professionals who demand reliable refractory materials. These blocks feature a high-alumina content, typically over 90%, thanks to their sillimanite and mullite-based composition. This gives them excellent stability at high temperatures and ensures they resist wear from slag and chemical corrosion.

We test every batch through strict protocols including thermal shock resistance, chemical analysis, and physical durability checks. This means you get consistent quality that holds up under tough conditions found in glass kilns, blast furnaces, and other high-temp environments. Our chemical breakdown shows low impurity levels, reducing risks of unexpected reactions during use.

In short, whether you’re handling glass production or heavy-duty metallurgy, these sillimanite refractory bricks deliver data-backed performance you can count on.

Versatile Applications From Glass Kilns to Blast Furnaces

Gotrays Sillimanite Ceramic Blocks fit a wide range of industries thanks to their durability and heat resistance. In the glass industry, these blocks are ideal for glass kiln sillimanite blocks, offering excellent thermal shock resistance and protection against molten glass slag. That means longer life and fewer shutdowns.

In metallurgy, they’re trusted for their ability to handle extreme temperatures in blast furnace throat bricks and other refractory linings. Their low thermal expansion helps maintain furnace stability even during rapid temperature changes.

The ceramics industry uses our sillimanite blocks for kiln furniture and furnace linings, benefiting from their high-alumina content and mullite-based strength. They keep production steady and reduce maintenance needs.

For cement plants, these blocks withstand corrosive environments, providing reliable slag-resistant ceramic blocks that extend equipment life and cut downtime.

No matter the sector, Gotrays Sillimanite Ceramic Blocks deliver consistent performance where heat, slag, and wear resistance matter most.

Gotrays Manufacturing Excellence From Raw Sillimanite to Custom Blocks Sustainability Edge

At Gotrays, we take pride in our manufacturing process, starting with high-quality raw sillimanite to create top-notch ceramic blocks. Our careful selection of raw materials from trusted sources ensures every block meets strict standards for durability and performance. From there, our advanced production techniques shape and fire the blocks to deliver the perfect balance of strength and thermal shock resistance.

We also offer custom sizing and shapes to fit your specific needs, whether it’s for blast furnace throat bricks, glass kiln sillimanite blocks, or high-temperature kiln furniture. This flexibility helps you get exactly what you need without compromise.

On the sustainability front, Gotrays is committed to eco-friendly practices. We optimize energy use during manufacturing and minimize waste, making our sillimanite ceramic blocks a greener choice. Plus, the long lifespan of our refractory bricks means fewer replacements and less environmental impact over time.

Choosing Gotrays means getting expertly crafted, reliable sillimanite ceramic blocks that align with your high-performance needs and sustainability goals.

Sizing Options Installation Tips and Maintenance Best Practices

At Gotrays, we understand that every project needs the right fit. Our sillimanite ceramic blocks come in a variety of sizes to match your specific application—whether you need high-alumina ceramic blocks for a glass kiln or slag-resistant bricks for a blast furnace throat. We also offer custom sizing to ensure your furnace lining or kiln furniture fits perfectly, reducing downtime and boosting efficiency.

Quick Install Guide

- Plan Your Layout: Measure your furnace or kiln area precisely.

- Dry Fit First: Arrange blocks without mortar to check fit and alignment.

- Use Proper Mortar: Choose high-temperature mortar compatible with sillimanite refractory bricks.

- Follow Cooling Protocols: Allow gradual cooling of the installed blocks to prevent thermal shock.

- Seal Joints: Ensure all joints are sealed to avoid slag or gas penetration.

Maintenance Tips

- Routine Inspections: Check for cracks or spalling at least once a month.

- Clean Surface Deposits: Remove slag or buildup gently to maintain corrosion resistance.

- Avoid Sudden Temperature Changes: Rapid heating or cooling can reduce block lifespan.

- Replace Damaged Blocks Promptly: This prevents damage from spreading and protects your process.

Maintenance FAQs

How often should I inspect the blocks?

Monthly inspections are recommended to catch early wear before issues arise.

Can I clean the blocks while in use?

Only when the system is cooled down to avoid thermal shock.

What’s the best way to handle block replacement?

Remove damaged blocks carefully and install new ones using the same size and mortar type.

Following these sizing, installation, and maintenance tips will help you get the most out of your sillimanite ceramic blocks, maximizing their durability and performance in demanding high-temperature environments.

Competitive Pricing and Easy Procurement with Gotrays

When it comes to buying sillimanite ceramic blocks, Gotrays offers competitive pricing tailored for U.S. customers without cutting corners on quality. We understand the cost pressures in industries like glass, metallurgy, and cement, so we make sure our high-alumina ceramic blocks deliver excellent value over the long haul.

Getting your order is hassle-free thanks to our streamlined procurement process. Whether you need standard sillimanite refractory bricks or custom-sized blocks, our team responds fast, helping you choose the right product and shipping it quickly to your site. We work closely with local logistics partners to keep delivery times short and costs low.

Why choose Gotrays for your ceramic refractory needs?

- Transparent pricing with no hidden fees

- Flexible order sizes to suit small or large projects

- Easy online ordering and support by phone or email

- Reliable delivery schedules across the United States

- Dedicated customer service focused on your satisfaction

With Gotrays, you get the best prices on mullite-based refractory blocks and slag-resistant ceramic blocks without sacrificing performance or service. Our goal is to make sourcing quality kiln furniture and blast furnace throat bricks as simple and cost-effective as possible.

Frequently Asked Questions Sillimanite Ceramic Blocks Answered

What makes Gotrays Sillimanite Ceramic Blocks stand out?

Our blocks offer excellent thermal shock resistance, low thermal expansion, and strong protection against slag corrosion. This means longer-lasting, more reliable furnace linings for your operation.

Can these blocks handle high temperatures in glass kilns and blast furnaces?

Yes, sillimanite refractory bricks are specifically designed for high-temperature environments like glass kilns, blast furnace throats, and other industrial furnaces.

How do Gotrays blocks compare to other mullite-based or kyanite-derived refractories?

Gotrays blocks deliver superior mechanical strength and durability thanks to our high-quality raw sillimanite and advanced manufacturing. This means better performance over time, especially in demanding applications.

Are the ceramic blocks customizable in size?

Absolutely. We offer a range of sizing options and can provide custom dimensions to fit your specific requirements.

What’s involved in installing and maintaining these ceramic blocks?

Installation is straightforward with our quick install guide. Regular inspections and cleaning are key to maintaining performance, and we provide maintenance tips to keep your linings in top shape.

Is Gotrays sillimanite ceramic block pricing competitive?

Yes, we balance quality with affordability and offer easy purchasing options tailored for US customers, helping you manage costs without sacrificing performance.

Can these blocks resist slag and corrosion effectively?

Our sillimanite ceramic blocks are engineered to resist slag corrosion, making them ideal for harsh industrial conditions where other materials may fail.

If you have more questions or need a detailed consultation, feel free to reach out. We’re here to ensure you get the right refractory solution for your business.

Related Gotrays Refractory Solutions

At Gotrays, we don’t just stop at sillimanite ceramic blocks. Our full range of refractory solutions is designed to meet diverse industrial needs across the U.S. If you need high-alumina ceramic blocks, mullite-based refractory bricks, or slag-resistant ceramic materials, we’ve got you covered.

Explore these related products for a complete refractory package:

- Sillimanite Refractory Bricks – Perfect for lining high-temperature kilns and furnaces.

- Andalusite Ceramic Refractories – Ideal for applications requiring excellent thermal stability.

- Kyanite-Derived Refractory Materials – Great for strong, long-lasting furnace linings.

- Thermal Shock Resistant Furnace Linings – Protect your equipment from rapid temperature changes.

- Blast Furnace Throat Bricks – Built to withstand extreme slag wear and thermal stress.

- Glass Kiln Sillimanite Blocks – Designed specifically for the glass industry’s demanding environments.

- High-Temperature Kiln Furniture – Durable support for your kiln components during firing.

All Gotrays refractory products come with our commitment to quality, US-based support, and competitive pricing. Whether you’re upgrading existing setups or building new installations, our solutions help maximize operational efficiency and longevity. Contact us to find the best combination for your facility.

Reviews

There are no reviews yet.