What Are Silicon Carbide Sleeves and Why Choose Gotrays

Silicon carbide sleeves are high-performance components made from sintered silicon carbide, a ceramic material known for its extreme hardness, corrosion resistance, and excellent thermal stability. These sleeves serve as protective liners or bushings in pumps, valves, and industrial machinery where wear and heat can quickly degrade standard materials. Their abrasion-proof nature ensures longer service life and reduces maintenance needs.

At Gotrays, we specialize in manufacturing premium silicon carbide sleeves with unmatched purity and precision. Our unique selling point lies in using reaction bonded silicon carbide (RB-SiC) and advanced sintering techniques to deliver consistent quality and reliability. Compared to standard alternatives, Gotrays sleeves offer:

- Higher purity levels, minimizing material imperfections

- Superior wear resistance for harsh environments

- Consistent dimensional accuracy for easy installation

Here’s a quick comparison of Gotrays silicon carbide sleeves vs common alternatives:

| Feature | Gotrays SiC Sleeves | Generic SiC Sleeves | Metal-Lined Sleeves |

|---|---|---|---|

| Purity | 98%+ reaction bonded SiC | 90%-95% sintered SiC | N/A |

| Wear Resistance | Excellent | Good | Moderate |

| Corrosion Resistance | Highly resistant | Moderate | Limited |

| Thermal Stability | Up to 1500°F (815°C) | Up to 1200°F (650°C) | Varies |

| Dimensional Tolerance | ±0.01 mm | ±0.05 mm | ±0.1 mm |

| Price | Competitive | Lower | Lower |

Choosing Gotrays means you get silicon carbide sleeves that last longer, perform better, and fit perfectly. Whether you need wear-resistant SiC shaft sleeves or corrosion-resistant ceramic pump sleeves, Gotrays stands out as the reliable choice for U.S. industries demanding durability and precision.

Key Properties and Technical Specifications of Gotrays SiC Sleeves

Gotrays Silicon Carbide sleeves stand out for their exceptional hardness and thermal stability. Made from high-purity sintered silicon carbide, these sleeves resist wear and corrosion far better than traditional metal or polymer options. This makes them perfect for tough environments where long-lasting performance matters.

Hardness and Thermal Stability

- Hardness rating of 9+ on Mohs scale, meaning strong abrasion resistance

- Thermal stability up to 1600°F (870°C), suitable for high-temperature applications

- Excellent chemical resistance to acids, alkalis, and salts

- Low thermal expansion keeps tight tolerances under heat stress

Here’s a quick look at the technical specs you can expect from Gotrays SiC sleeves:

| Property | Specification |

|---|---|

| Material | Sintered Silicon Carbide |

| Hardness | Mohs 9+ (Near diamond) |

| Maximum Operating Temp | 1600°F / 870°C |

| Density | 3.1 g/cm³ |

| Thermal Expansion | 4.0 x10⁻⁶ /°C |

| Typical Applications | Pump sleeves, valve liners, bearings, seals |

Need to know how hot these sleeves can go? The max operating temperature is 1600°F, making them ideal for industrial machinery and fluid handling pumps working under extreme heat conditions.

Gotrays Silicon Carbide sleeves offer a perfect mix of toughness and precision, making them a smart upgrade for anyone dealing with wear-resistant SiC shaft sleeves or ceramic pump sleeves in challenging US markets.

Applications Where Gotrays Silicon Carbide Sleeves Excel

Gotrays silicon carbide sleeves are a top choice for tough industrial settings because they handle wear and corrosion better than most materials. Here’s where they really shine:

Pumps and Fluid Handling

- Ideal for corrosion-resistant ceramic pump sleeves.

- Perfect for situations with abrasive or acidic fluids.

- Help reduce leaks and extend pump life by resisting wear.

Industrial Machinery Uses

- Work great as wear-resistant SiC shaft sleeves in heavy machinery.

- Protect moving parts from abrasion and damage over time.

- Improve reliability in grinder drums and other mechanical seals.

Harsh Environment Applications

- Built to withstand high-temperature SiC seal sleeve demands.

- Perform well under pressure, heat, and corrosion.

- Perfect for chemical processing, power plants, and mining operations.

Case Study on Downtime Reduction

One U.S. industrial plant replaced their old liners with Gotrays reaction bonded SiC bearing sleeves. They saw a 30% drop in unplanned downtime, thanks to the sleeves’ durability and resistance to wear. This meant fewer replacements and less maintenance, saving time and costs.

In short, Gotrays silicon carbide sleeves fit wherever long-lasting, abrasion-proof silicon carbide tubes or liners are needed. They keep equipment running smoothly in the toughest jobs.

Customization and Sizing Options for Your Needs

At Gotrays, we know every project is different. That’s why our silicon carbide sleeves come with flexible sizing and customization options to fit your exact requirements. Whether you need a small wear-resistant SiC shaft sleeve or a large corrosion-resistant ceramic pump sleeve, we’ve got you covered.

Specification Guide with OD and ID Tolerances

- Outer Diameter (OD) ranges from 10mm to 300mm

- Inner Diameter (ID) customizable to your specs, ensuring a perfect fit

- Tolerances held tight at ±0.02mm for reliable performance

- Length options available in increments to match your machinery needs

Our precise tolerances guarantee smooth installation and optimum sealing, reducing wear and tear over time.

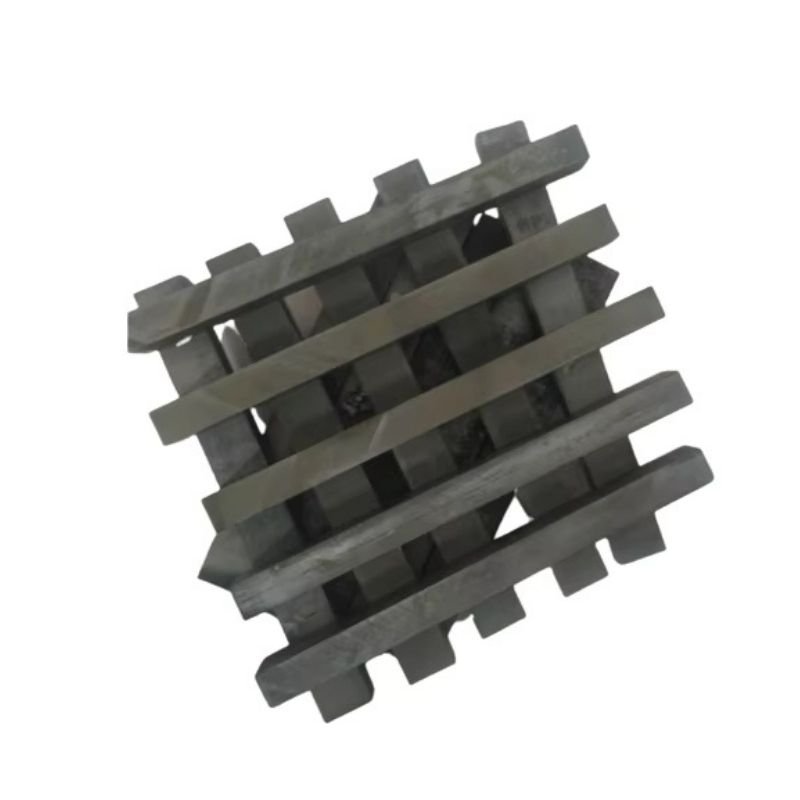

Visual Size Chart Overview

We provide an easy-to-read size chart to help you pick the right dimensions quickly. The chart lists standard silicon carbide liner sizes alongside custom dimensions, making it simple to find or request what you need without guesswork.

If you’re looking for custom SiC mechanical seal components or a special sintered silicon carbide liner, just reach out. Our team will guide you through the sizing and customization process to ensure your project runs smoothly with Gotrays sleeves.

Benefits of Upgrading to Gotrays SiC Wear-Resistant Sleeves

Switching to Gotrays silicon carbide sleeves brings clear advantages you’ll notice right away. Here’s what makes these SiC wear-resistant sleeves a smart choice:

Cost Savings

- Long-lasting durability means fewer replacements and less downtime.

- Reduced wear lowers the risk of costly repairs to pumps, valves, and other equipment.

- Energy efficiency improves because friction is minimized, saving on operational costs.

Easy Installation

- Gotrays sleeves come with precise sizing and tight tolerances, so they fit smoothly without extra mods.

- Our sleeves work as drop-in replacements compatible with most industrial and fluid handling systems.

- Installation is quick and straightforward, letting you get machines back up fast.

Eco-Friendly Advantages

- Made from sintered silicon carbide, our sleeves require less frequent replacement, cutting down on waste.

- The manufacturing process is optimized to reduce emissions and energy use.

- By extending equipment lifespan, Gotrays helps companies reduce their environmental footprint.

ROI Calculator Overview

- We offer an ROI calculator to help you estimate your savings based on operational hours, replacement costs, and downtime.

- This tool makes it easy to see the financial benefits of upgrading to Gotrays SiC sleeves before buying.

- The calculator factors in energy savings, maintenance costs, and sleeve lifespan for a full view of your investment payoff.

Upgrading to Gotrays SiC wear-resistant sleeves gives you a durable, eco-conscious solution that saves money over time—making it a practical choice for any U.S.-based industry demanding high-performance silicon carbide liner components.

Quality Assurance Certifications and Why Trust Gotrays

At Gotrays, quality is our top priority. Our silicon carbide sleeves undergo strict testing to meet ISO 9001 standards, ensuring consistency and reliability in every product. We also perform ASTM testing to confirm our SiC sleeves’ toughness, wear resistance, and corrosion protection, giving you peace of mind when choosing us.

We back our sleeves with solid warranties because we stand behind their performance. Many of our U.S. customers have shared positive testimonials highlighting improved equipment lifespan and reduced downtime after switching to Gotrays SiC ceramic bushings and liners.

Choosing Gotrays means you get:

- Certified quality meeting international standards

- Tested durability in harsh environments

- Warranty coverage for long-term use

- Proven customer satisfaction across industries

This commitment makes Gotrays a trusted partner for wear-resistant SiC shaft sleeves and other silicon carbide components in the U.S. market.

How to Buy Gotrays Silicon Carbide Sleeves Pricing MOQ and Shipping

Buying Gotrays silicon carbide sleeves is straightforward and customer-friendly. We offer clear pricing tiers that fit different order sizes, so whether you need a single custom SiC ceramic bushing or bulk quantities, we’ve got you covered.

Pricing and Minimum Order Quantity (MOQ)

- Competitive pricing based on volume

- Flexible MOQ starting from small orders for custom SiC mechanical seal components

- Discounts available for large purchases of wear-resistant SiC shaft sleeves

Request a Quote or Sample

- Easily get a personalized quote through our website or customer service

- Sample orders available to test reaction bonded SiC bearing sleeves before committing

- Quick response time to help you make the best choice

Fast Regional Shipping

- Multiple shipping hubs across the U.S. ensure quick delivery

- Options for expedited shipping available

- Reliable packaging designed to protect abrasion-proof silicon carbide tubes during transit

With Gotrays, you’re buying more than just silicon carbide valve liners—you’re investing in quality, availability, and support tailored for your industrial needs. Reach out today for a quote or ask about our sample program.

Frequently Asked Questions About Silicon Carbide Bushings and Sleeves

Here are some common questions we get about silicon carbide bushings and sleeves, answered clearly to help you understand their uses and benefits.

What is a silicon carbide sleeve used for?

Silicon carbide sleeves, also called SiC ceramic bushings or liners, protect shafts and pumps from wear, corrosion, and high temperatures. They’re common in industrial machinery, chemical pumps, and harsh environments where regular metal parts fail faster.

How does Gotrays silicon carbide sleeves compare to other brands?

Gotrays offers high-purity reaction bonded SiC, giving better hardness, thermal stability, and wear resistance than many alternatives. Our sleeves last longer, reduce downtime, and handle more aggressive fluids without corroding.

What is the maximum temperature Gotrays silicon carbide sleeves can handle?

Our SiC sleeves withstand temperatures up to 1600°F (870°C), making them ideal for high-temperature seal and pump applications. This thermal stability outperforms many abrasive-proof silicon carbide tubes and liners on the market.

Can these sleeves be customized to fit specific equipment?

Yes, Gotrays provides custom sizing options with tight OD/ID tolerances to fit your machinery perfectly. We also offer consultation to select the right specifications for your unique needs.

What industries benefit most from silicon carbide wear-resistant sleeves?

Common industries include chemical processing, petroleum, pulp and paper, and power generation. Anywhere corrosion-resistant ceramic pump sleeves or abrasion-proof SiC liners are needed, these sleeves excel.

Are silicon carbide sleeves difficult to install?

Not at all. They’re designed for easy installation and fit replacement parts to minimize downtime. Their durability also means fewer maintenance interruptions.

How do silicon carbide bushings reduce operational costs?

Due to their hardness and corrosion resistance, these bushings last longer and reduce the need for frequent replacements. This leads to significant cost savings and better ROI over time compared to metal or lower-grade ceramic sleeves.

If you have more questions or want a quote for Gotrays silicon carbide sleeves, contact us today to get expert help and fast delivery across the US.

Reviews

There are no reviews yet.