What Are Silicon Carbide Bricks A Complete Guide

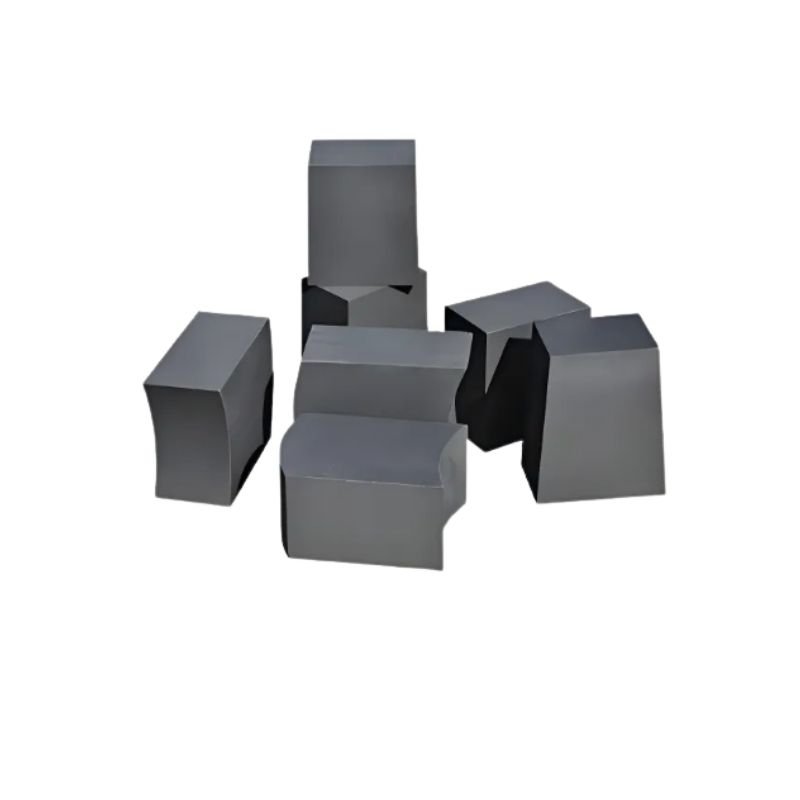

Silicon carbide bricks, commonly known as SiC bricks, are advanced refractory materials designed to withstand extreme temperatures and harsh industrial environments. They play a critical role in protecting furnace linings and other high-temperature equipment from wear, corrosion, and thermal shock.

Composition and How SiC Bricks Are Made

SiC bricks consist primarily of silicon carbide particles bonded together, often with a small amount of free silicon or a bonding phase. The manufacturing process typically involves:

- Raw Materials: High-purity silicon carbide powder combined with binders or sintering agents.

- Forming: The mixture is shaped into bricks through pressing or molding techniques.

- Sintering: Bricks are heated at extremely high temperatures (over 2200°F) causing the particles to fuse into a dense, hard structure.

There are two main types of bonding methods used:

- Clay Bonded SiC Bricks: Use a traditional clay binder for moderate refractory performance.

- Nitride Bonded Silicon Carbide: Employs nitriding to create a dense, chemically resistant microstructure with superior mechanical strength.

Why Silicon Carbide Bricks Outperform Traditional Refractories

Silicon carbide bricks offer several advantages over conventional refractory materials:

- High Thermal Conductivity: Enables faster heat transfer and energy efficiency.

- Excellent Thermal Shock Resistance: Withstands rapid temperature changes without cracking.

- Superior Wear and Abrasion Resistance: Ideal for harsh industrial conditions like steelmaking and glass production.

- Chemical Stability: Resistant to corrosive environments such as slags and molten metals.

This combination of properties makes SiC bricks the go-to choice for industries seeking durable, efficient, and cost-effective refractory solutions.

Types of SiC Bricks Available from Gotrays

At Gotrays, we offer two main types of silicon carbide bricks to match your specific needs: Clay Bonded SiC Bricks and Nitride Bonded Silicon Carbide Bricks. Understanding the difference helps you pick the right brick for your operation.

Clay Bonded SiC Bricks

- Made with silicon carbide grains mixed with clay as a binder

- Great for general high-temperature applications where moderate wear and corrosion resistance is needed

- Often used in applications where thermal shock resistance is key but extreme chemical resistance is less critical

Nitride Bonded SiC Bricks

- Made using a silicon nitride bonding process, resulting in a denser, tougher brick

- Superior in abrasion resistance and corrosion protection

- Ideal for harsher environments like blast furnaces and chemical processing units where longer lifespan and resistance to slag are required

Choosing the Right Variant

- Consider thermal shock resistance, abrasion and chemical attack levels in your operation

- Clay bonded bricks typically suit moderate wear and less aggressive environments

- Nitride bonded bricks fit heavy-duty use where durability and longer service life pay off

Custom SiC Brick Solutions for Your Industry Needs

We know one size doesn’t fit all. Gotrays provides custom silicon carbide brick solutions tailored to the exact size, shape, and performance standards your project demands. Whether you’re running a steel plant, glass kiln, or chemical facility anywhere in the U.S., we deliver bricks built to fit your needs and local industry standards.

Exceptional Properties of Gotrays SiC Refractory Bricks

Gotrays Silicon Carbide Bricks stand out for their toughness and reliability in tough industrial settings. Here’s why our SiC refractory bricks are a top choice for U.S. industries:

- High Thermal Conductivity – Our SiC bricks quickly transfer heat, helping your kiln or furnace maintain consistent temperatures and improve energy efficiency.

- Thermal Shock Resistance – These bricks handle rapid temperature changes without cracking, making them perfect for blast furnaces and steel ladles.

- Abrasion and Wear Resistance – Gotrays SiC bricks resist abrasion and corrosion, prolonging furnace lining life and reducing downtime.

- Excellent Chemical Stability – They withstand aggressive chemicals found in aluminum electrolysis and chemical processing, reducing maintenance needs.

- Superior Mechanical Strength – Our bricks maintain shape and integrity even under heavy mechanical stress and extreme environments.

Technical Specifications Table

| Property | Clay Bonded SiC Brick | Nitride Bonded SiC Brick |

|---|---|---|

| SiC Content (%) | 65 – 95 | 90+ |

| Bulk Density (g/cm³) | 3.0 – 3.15 | 3.15 – 3.25 |

| Thermal Conductivity (W/mK) | 25 – 40 | 40 – 55 |

| Cold Crushing Strength (MPa) | 80 – 120 | 150 – 250 |

| Max Service Temperature (°F) | 3200 | 3700 |

| Thermal Shock Resistance | Very Good | Exceptional |

| Abrasion Resistance | High | Very High |

With these properties, Gotrays SiC refractory bricks deliver unmatched performance, suited perfectly for high-temperature US operations needing durability, energy savings, and low maintenance.

Key Applications of Silicon Carbide Bricks in High Temp Industries

Silicon carbide bricks (SiC bricks) are tough and reliable, making them perfect for high-temperature industrial uses. Here’s where they shine the most:

Steel and Metal Smelting

SiC bricks are a go-to for blast furnaces, ladles, and converters in steel production. Their high thermal conductivity and wear resistance help keep the equipment running longer under extreme heat and pressure.

Glass Kilns and Ceramic Furnaces

In glassmaking and ceramics, SiC bricks resist thermal shock and abrasion, ensuring kiln linings last longer and maintain stable temperatures during rapid heating and cooling cycles.

Aluminum Electrolysis and Chemical Processing

Nitride bonded and clay bonded SiC bricks are widely used in aluminum electrolysis cells and chemical reactors. Their resistance to corrosion and high temperature helps improve efficiency and reduce downtime.

Local Stock for US Steel Plants

Gotrays keeps a reliable inventory of SiC bricks in key US hubs, making it easy to supply steel plants quickly when they need replacements or upgrades. This local availability supports faster project turnarounds and lower shipping costs.

SiC refractories are essential for industries that demand durable, high-performance linings in extreme conditions, helping operators boost productivity and cut maintenance times.

Benefits of Choosing Gotrays SiC Bricks for Your Operations

When you pick Gotrays Silicon Carbide Bricks for your furnace or kiln lining, you’re investing in durability and efficiency that directly impact your bottom line. Here’s why our SiC bricks stand out:

Cost Savings

- Longer service life means fewer replacements, cutting down your maintenance expenses.

- Higher wear resistance reduces downtime caused by lining failures.

- The durability of our bricks means you get more value per dollar spent.

Energy Efficiency

- Gotrays SiC bricks have high thermal conductivity, helping your equipment heat up faster and maintain consistent temperatures.

- This efficiency translates to lower fuel or electricity consumption, saving you money on operational costs.

Installation and Maintenance Best Practices

- Our SiC bricks come in standard and custom sizes, simplifying installation and reducing labor time.

- For the best performance, install with proper mortar that matches our SiC brick types (clay bonded or nitride bonded).

- Routine inspections extend your refractory lining life—spot early signs of wear and address them promptly.

- Gotrays technical support provides guidance to optimize your installation and maintenance procedures.

Choosing Gotrays SiC refractory bricks means less hassle, better performance, and real savings in your high-temperature industrial processes.

Gotrays Manufacturing Excellence From Raw SiC to Finished Brick

At Gotrays, quality starts with selecting the best raw silicon carbide material. We source high-purity SiC to ensure every brick meets strict performance standards. From there, our advanced manufacturing process transforms this raw SiC into durable refractory bricks designed to handle extreme heat and tough industrial conditions.

Our production includes precise mixing, molding, and firing techniques that give our silicon carbide bricks their signature toughness, thermal shock resistance, and abrasion resistance. Whether it’s nitride bonded silicon carbide or clay bonded SiC bricks, Gotrays controls every step to deliver consistent, high-quality products.

We also invest in rigorous testing—checking thermal conductivity, density, and wear resistance—to guarantee our bricks hold up in real-world steel plants, aluminum electrolysis cells, and glass kilns across the US. Our streamlined supply chain and local stock hubs mean faster delivery and better support for American industries relying on SiC refractory bricks.

When you choose Gotrays, you’re getting more than just a brick. You’re tapping into a proven manufacturing expertise built to meet the demands of today’s high-temperature applications without compromise.

Why Gotrays Trusted SiC Brick Supplier Worldwide

At Gotrays, we’ve built a reputation as a reliable supplier of Silicon Carbide bricks across the globe, especially here in the U.S. Our customers trust us because we deliver consistent quality that stands up in tough industrial environments. When you choose Gotrays SiC bricks, you’re getting products tested and proven in real-world furnaces operating in steel plants, glass kilns, and aluminum electrolysis cells.

Case Studies Showing Proven Results

We back our products with real data. Our case studies highlight how Gotrays SiC refractory bricks improve furnace performance by:

- Extending service life by reducing wear and thermal shock damage

- Lowering maintenance downtime and replacement costs

- Enhancing energy efficiency thanks to superior thermal conductivity

These success stories come from steel mills and metal smelters in key U.S. hubs, proving our bricks perform under the demanding conditions you face every day.

Sustainability and Certifications

Gotrays cares about the environment. Our manufacturing processes focus on reducing waste and energy use, aligning with today’s sustainability goals. Plus, Gotrays SiC bricks meet important industry standards and certifications, ensuring safety, reliability, and compliance across all applications. This commitment not only supports green operations but also guarantees that you receive high-quality, eco-friendly refractory materials.

Choosing Gotrays means partnering with a supplier who stands by their Silicon Carbide bricks with proven results, trusted performance, and a responsible approach to manufacturing.

Frequently Asked Questions About SiC Bricks

What are Silicon Carbide Bricks used for?

SiC bricks are widely used in high-temperature industries like steelmaking, metal smelting, glass production, aluminum electrolysis, and chemical processing. They provide durable, heat-resistant linings for furnaces, kilns, and ladles.

What makes SiC bricks better than traditional refractories?

They offer higher thermal conductivity, excellent thermal shock resistance, and superior abrasion resistance. This means longer service life and less downtime compared to traditional fireclay or alumina bricks.

What’s the difference between clay bonded and nitride bonded SiC bricks?

Clay bonded SiC bricks have a more flexible structure, suited for general-use furnace linings. Nitride bonded SiC bricks are denser and tougher, ideal for areas facing extreme wear and corrosion.

Can I get custom SiC bricks for my specific industry?

Yes, Gotrays offers custom solutions tailored to your process needs, ensuring the best fit for your operations whether it’s steel plants, glass kilns, or chemical reactors.

How should I maintain SiC bricks for best results?

Regular inspection, proper installation, and avoiding sudden temperature changes help extend their lifespan. Cleaning furnace linings to remove buildup also keeps them in top shape.

Are Gotrays SiC bricks stocked in the U.S.?

Yes, we maintain local stock hubs across the United States to ensure fast delivery and support for your production schedules.

If you have more questions about choosing or using Silicon Carbide Bricks, feel free to reach out to our experts at Gotrays anytime.

Ready to Upgrade Your Refractory Lining Contact Gotrays Today

If you’re looking to boost efficiency, cut costs, and extend the life of your high-temperature operations, it’s time to consider Gotrays Silicon Carbide Bricks. Whether you need wear-resistant furnace lining for steel plants, abrasion-resistant SiC material for aluminum electrolysis, or thermal shock resistant bricks for glass kilns, we’ve got the right solution for you.

At Gotrays, we offer local stock across key US hubs to ensure fast delivery and reliable support. Our SiC refractory bricks, including nitride bonded and clay bonded silicon carbide options, are designed to meet the toughest industry demands with outstanding performance.

Reach out today for a custom recommendation or to get a quote. Our team is ready to help you upgrade your refractory lining and improve your furnace operation with quality you can trust. Don’t wait—partner with Gotrays, your trusted supplier of high thermal conductivity refractory bricks in the United States.

Reviews

There are no reviews yet.