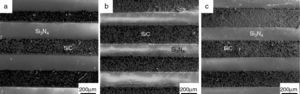

Nitride-Bonded SiC Pump Part and Impeller Overview

Looking for a pump impeller that stands up to the toughest industrial conditions? Our Nitride-Bonded Silicon Carbide (SiC) Pump Parts and Impellers deliver unmatched durability and performance for demanding applications. Engineered with advanced Si3N4-SiC ceramics, these impellers resist wear, corrosion, and extreme temperatures—keeping your pumps running longer with less downtime.

![Image of Nitride-Bonded SiC Pump Impeller]

Gotrays Brand Badge

Trusted by industry leaders, Gotrays specializes in cutting-edge pump components designed for reliability and efficiency.

Key Highlights

- Superior abrasion and corrosion resistance for harsh slurry and chemical environments

- High temperature tolerance up to 1600°F for power plants and chemical processing

- Lightweight design reduces stress on pump shafts and improves energy efficiency

- Precision reaction bonded SiC manufacturing ensures dimensional accuracy and strength

- Compatible with OEM and aftermarket pumps across mining, power, and metallurgy sectors

Ready to upgrade your pumps? Explore how Gotrays Nitride-Bonded SiC impellers can maximize your equipment’s life and performance.

Get Your Quote Today [Call to Action Button]

Technical Specifications

| Specification | Details |

|---|---|

| Material Composition | Silicon Nitride (Si3N4) bonded with Silicon Carbide (SiC) |

| Density | Approximately 3.2 g/cm³ |

| Hardness | 1500–1900 HV (Vickers Hardness) |

| Wear Rate | Ultra-low wear rate ideal for abrasive slurries |

| Corrosion Resistance | Excellent resistance to acids, alkalis, and solvents |

| Temperature Tolerance | Up to 1400°F (760°C) continuous operation |

| Weight Reduction | Up to 40% lighter than high-chrome alloy impellers |

| Dimensions Compatibility | Custom sizes available; fits standard pump models |

| Additional Notes | Reaction bonded for superior strength and durability |

This nitride-bonded SiC pump impeller combines high-density ceramic materials with exceptional hardness to reduce wear and extend service life. Its corrosion resistance and temperature tolerance make it perfect for tough industrial environments in mining, chemical processing, and power plants. Plus, the lightweight design helps improve pump efficiency without compromising durability.

Features and Material Benefits

Our Nitride-Bonded SiC Pump Parts and Impellers bring top-notch durability where it counts. They offer exceptional abrasion and erosion resistance, making them last longer even in the harshest slurry and chemical environments. The material’s natural cavitation resistance protects your pump from damage caused by vapor bubbles—keeping performance steady and maintenance low.

Thanks to their low friction surface, these Si3N4-SiC impellers run smoother, reducing wear on pump components and lowering energy costs. While ceramic materials can be brittle, our specialized bonding process boosts toughness, giving you a balance of strength and durability you can rely on.

Si3N4-SiC vs High-Chrome Alloy Comparison

| Feature | Si3N4-SiC Impeller | High-Chrome Alloy Impeller |

|---|---|---|

| Abrasion Resistance | Very High | Moderate |

| Erosion Resistance | Excellent | Good |

| Cavitation Resistance | Superior | Average |

| Friction Coefficient | Low | Higher |

| Toughness | Improved brittle toughness | High toughness, but wears faster |

| Corrosion Resistance | Very Good (especially acidic) | Moderate |

| Weight | Lighter than metal alloys | Heavier |

Choosing Nitride-Bonded SiC impellers means opting for longer life, better wear protection, and less downtime, making them ideal for demanding industries right here in the U.S.

Applications and Use Cases

Our Nitride-Bonded SiC Pump Part / Impeller is built tough for heavy-duty industries across the U.S. It’s a top choice for sectors where harsh conditions and abrasive materials wear down ordinary parts fast.

Key Industries

- Coal Fired Power Plants – Handles high abrasion from slurry and ash, boosting pump uptime.

- Mining and Tailings – Perfect for handling coarse solids and slurry, extending equipment life in challenging environments.

- Chemical Processing – Resistant to corrosion and chemical attack, great for acidic or caustic fluids.

- Non-Ferrous Metallurgy – Reliable for processing ores and concentrates, reducing downtime and maintenance costs.

Case Study Snapshot

One U.S. mining operation switched to our Si3N4-SiC impellers and saw a 40%+ increase in impeller life compared to their previous high-chrome alloy parts. This upgrade cut replacement frequency and saved thousands in maintenance and downtime annually.

Our wear-resistant SiC pump components are trusted across these sectors for lasting performance when it counts most.

Manufacturing and Quality Assurance

At Gotrays, every nitride-bonded SiC pump part and impeller is made using advanced reaction sintering technology. This process ensures a strong, uniform bond between the silicon nitride and silicon carbide for exceptional durability. We also integrate metal lining where needed to boost performance and fit directly with your pump assembly.

Our facility is ISO 9001 certified, so quality is built into every step. We run strict ASTM wear tests and use fluorescence penetrant inspection to catch even the smallest defects before shipping. This means you get reliable, wear-resistant SiC pump components ready for the toughest conditions.

Customization is a big part of what we offer. Whether you need specific vane geometry, bore sizes, or OEM and ODM options, we work with you to tailor the impeller or pump part to your exact specs. It’s all about delivering parts that fit perfectly and perform reliably in your industrial pumps.

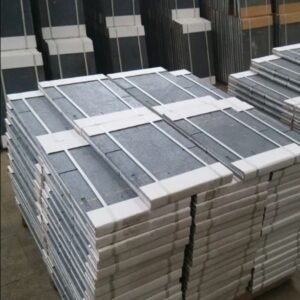

Pricing and Availability

We offer tiered pricing on our Nitride-Bonded SiC Pump Parts and Impellers to fit different project sizes and budgets. Whether you need a single replacement impeller or a full set for a large operation, you’ll find competitive rates that scale with volume.

Stock Status

Our Si3N4-SiC impellers and related pump parts are stocked locally in the US for fast shipping. This means minimal downtime and quick delivery, keeping your operations running smoothly.

Volume Discounts

Buying in bulk? You’ll benefit from volume discounts that lower your overall cost. We work closely with mining, power, and chemical plants to ensure pricing flexibility for large orders without sacrificing quality.

Contact us for a custom quote tailored to your specific needs and get the best value on abrasion-resistant SiC pump components built to last.

Customer Reviews and Testimonials

Our Nitride-Bonded SiC Pump Parts and Impellers have earned top marks from users across mining, power, and chemical industries in the U.S. Verified buyers consistently highlight:

- Exceptional durability that outlasts high-chrome alternatives

- Wear resistance that keeps production running longer with less downtime

- Smooth performance in tough slurry applications with minimal maintenance

Here’s what one of our clients in coal-fired power said:

“Swapping to the Si3N4-SiC impeller from Gotrays cut our wear issues in half and extended run time by months. Truly a game changer for our plant’s reliability.”

We also have several video testimonials available that dive into real-world benefits and installation tips—helping new customers get the most out of their NBSC pump parts from day one.

Related Products and Upsells

Enhance your pump system’s performance with our range of related products designed to work seamlessly with the Nitride-Bonded SiC Pump Part and Impeller. Choose from:

-

Ceramic Throat Bushes

Boost wear resistance and extend pump life, especially in abrasive slurry environments.

-

Silicon Nitride Bonded SiC Volute Liners

Protect your pump casing with high-durability liners made to handle tough chemical and mining applications.

-

Shaft Sleeves

Durable, corrosion-resistant sleeves that prevent shaft wear and reduce maintenance costs.

-

Installation Kits

Get everything you need for a smooth, precise impeller installation—tools, gaskets, and alignment guides included.

-

Wear Monitoring Sensors

Stay ahead of maintenance with real-time wear data to avoid unexpected downtime and optimize pump performance.

These accessories and wear-resistant pump components complement your ceramic slurry pump impeller, ensuring maximum uptime and reliability across industries like mining, power generation, and chemical processing.

FAQ and Support

Here are answers to the most common questions we hear about our Nitride-Bonded SiC Pump Parts and Impellers:

What is the typical warranty on Gotrays Si3N4-SiC impellers?

We back our pump parts with a standard 12-month warranty covering defects in materials and workmanship. Extended warranty options are available for bulk orders or custom projects.

How do I know if the SiC pump impeller fits my equipment?

Check our compatibility guide or send us your pump model details. Our team can confirm fit or help customize the impeller to your OEM specs.

Can you customize vane geometry or bore sizes?

Yes, we offer OEM and ODM customization to optimize performance and extend service life based on your slurry and operational conditions.

What kind of support do you offer after purchase?

We provide technical support via phone and email for installation advice, troubleshooting, and maintenance tips tailored to your specific application.

How long does shipping take in the US?

Most standard parts ship within 3-5 business days. Custom units vary but we’ll provide clear timelines upfront.

Do you offer repair or refurbishing services?

Currently, we focus on new manufacturing but can guide you on maintenance and replacement best practices.

If your question isn’t listed, contact our support team directly. We’re here to ensure your infusion of corrosion-resistant, abrasion-resistant Silicon Nitride bonded SiC pump parts keeps your operations running smoothly.

Get Your Spec Sheet and Expert Support

Ready to see the full details on our Nitride-Bonded SiC Pump Part / Impeller? Download the spec sheet now for complete technical info and dimensions.

Have questions or need help choosing the right Si3N4-SiC impeller for your pump? Our engineering team is here to assist you with personalized consultation tailored to your application.

Contact us today to get expert advice and ensure your next pump upgrade fits perfectly and performs reliably.

Why Choose Gotrays Si3N4 SiC Impellers for Your Industrial Pumps

When it comes to reliable pump parts, Gotrays Si3N4-SiC impellers stand out for a reason. We know you’re dealing with tough conditions—abrasive slurries, corrosive chemicals, and constant wear. That’s why our nitride-bonded SiC pump impeller is built to handle it all without fail.

How Gotrays Solves Your Pump Challenges

- Longer Service Life: Our Si3N4 bonded SiC impellers resist abrasion and erosion far better than standard high-chrome alloy parts. That means less downtime for you.

- Better Performance: Low friction design improves pump efficiency, cutting energy costs on every run.

- Tough and Reliable: Unlike brittle ceramics, our nitride bonding gives the impeller extra toughness to withstand shocks and cavitation.

- Local Shipping: Based right here in the US, we offer fast shipping to minimize your waiting time and keep your projects on schedule.

- Custom Fit: We work with your specs—vane geometry, bore sizes—so your pumps operate exactly the way you need.

Choosing Gotrays means investing in a high-quality, wear-resistant SiC pump component made specifically for the demands of American industries like mining, power, and chemical processing. We’ve got the materials science, manufacturing skill, and local support to back you up.

Key Features and Technical Specifications

Our Nitride-Bonded SiC Pump Part / Impeller stands out thanks to its advanced material makeup and performance specs designed for tough industrial use. Below is a quick glance at what makes these impellers a go-to choice in the US market.

Interactive Specs Table

| Feature | Description |

|---|---|

| Material Composition | Silicon Nitride bonded Silicon Carbide (Si3N4-SiC) |

| Density | Approx. 3.2 g/cm³ |

| Hardness | 2200–2400 HV |

| Wear Rate | Extremely low abrasion rate |

| Corrosion Resistance | High resistance to acids and alkalis |

| Temperature Tolerance | Up to 1100°F (600°C) |

| Weight Reduction | Up to 40% lighter than metal impellers |

| Dimensions | Customizable to OEM specs |

| Compatibility | Fits standard pump models used in mining, power, and chemical industries |

Superior Material Science Si3N4-SiC Explained

Our Si3N4-SiC impellers combine silicon nitride and reaction-bonded silicon carbide to deliver unmatched toughness and longevity. This mix gives you:

- High abrasion resistance to handle slurry, tailings, and corrosive fluids without breaking down.

- Excellent corrosion resistance, letting your pump parts last longer in aggressive environments.

- Impressive thermal stability to withstand high operating temperatures without warping.

- Reduced weight that improves pump efficiency and lowers energy costs.

SiC vs High Chrome Impeller Comparison

| Attribute | Si3N4-SiC Impeller | High Chrome Alloy Impeller |

|---|---|---|

| Abrasion Resistance | Superior—lasts significantly longer in slurry and abrasive media | Good, but prone to faster wear under severe conditions |

| Corrosion Resistance | Excellent in acidic and alkaline environments | Moderate resistance, susceptible to corrosion |

| Weight | Up to 40% lighter for better efficiency | Heavier, increasing energy use |

| Brittleness | Low brittleness, better toughness | More brittle, can crack under impact |

| Maintenance | Longer service intervals | Requires frequent replacements |

By choosing silicon nitride bonded SiC impellers, you’re investing in pump parts built to endure the US industrial landscape, reduce downtime, and save operating costs.

Ideal Applications in Mining Power and Chemical Industries

Our Nitride-Bonded SiC Pump Parts and Impellers shine in tough environments where durability matters most. They are purposely built for industries like mining, power generation, and chemical processing, where abrasive and corrosive conditions are common.

Key Uses

- Tailings Handling: Perfect for slurry pumps moving abrasive mining waste without wearing down fast.

- FGD Scrubbers: Handles acidic and corrosive gases in flue gas desulfurization systems with strong chemical resistance.

- Acid Leaching: Withstands harsh chemicals during metal extraction, keeping your pumps running longer and reducing downtime.

Real World Case Studies

Clients in Colorado and Texas mining operations report up to 40% longer impeller life with our Si3N4-SiC impellers compared to traditional high-chrome alloys. Power plants using FGD scrubbers in Georgia praise the corrosion resistance and lower maintenance costs.

Local Intent and Certified Parts

We provide parts that meet strict ISO 9001 quality standards and are readily available from U.S. warehouses for fast delivery. Gotrays’ pump components are designed for compatibility with common OEM pumps used across North America, keeping your operations smooth without delay.

Custom Manufacturing and Quality Standards at Gotrays

At Gotrays, we take pride in our precise custom manufacturing process for nitride-bonded SiC pump parts and impellers. Our approach starts with advanced reaction sintering followed by CNC machining to ensure tight tolerances and perfect fit. Each component undergoes rigorous testing—including ASTM wear tests and fluorescence penetrant inspection—to guarantee durability and reliability for your specific application.

We offer full OEM compatibility, making it easy to replace or upgrade your existing pump parts with our Si3N4-SiC impellers. Plus, we provide customization options, including various vane geometries and bore sizes to match your pump’s exact needs.

Our manufacturing meets high-quality standards backed by ISO 9001 certification. We also supply FDA-compliant variants for industries that demand strict material safety, all while maintaining the robust performance you expect from wear-resistant SiC pump components.

Installation Guide and Maintenance Tips

Installing your nitride-bonded SiC pump part or impeller properly makes all the difference in performance and lifespan. Follow these simple steps to get started:

- Alignment: Ensure the impeller aligns perfectly with the pump shaft to avoid uneven wear or vibration.

- Torque Specs: Use the manufacturer-recommended torque settings on all bolts and fasteners to secure parts firmly without damage.

- Step-by-step Video: Check out our detailed installation video for a clear visual guide.

Pro Tips for Maximizing Impeller Lifespan

- Monitor Wear Regularly: Keep an eye on the impeller surfaces and pump parts for signs of wear or erosion.

- Track Slurry pH: Maintaining the right pH balance in slurry handling prevents corrosion and extends part life.

- Routine Maintenance: Schedule regular inspections and cleanings to remove build-up and avoid cavitation damage.

- Use Wear Sensors: Consider installation of wear monitoring sensors for early detection of potential issues.

Following these guidelines helps you get the most out of your silicon nitride bonded SiC impeller and keeps your pump running smooth longer.

Pricing Availability and Why Gotrays Delivers Value

At Gotrays, we keep pricing straightforward and transparent. Our Nitride-Bonded SiC Pump Parts and Impellers come with clear tiered pricing based on volume, so whether you’re ordering a single replacement or stocking up for multiple pumps, you get fair rates.

We understand local businesses need quick access, so we maintain strong inventory levels across the US to ensure fast shipping and minimal downtime. Plus, bulk orders unlock additional discounts—perfect for contractors and operators managing large fleets or multiple sites.

To help you make the best decision, we offer an easy-to-use ROI calculator right on our site. This tool highlights long-term savings from switching to our wear-resistant SiC ceramic slurry pump impellers versus traditional high-chrome alloy parts.

Request a custom quote anytime—our local support team is ready to assist with pricing details, lead times, and delivery options. Choose Gotrays for dependable, cost-effective reaction bonded silicon carbide pump parts that keep your operations running smooth and profitable.

Frequently Asked Questions FAQ

What is a Nitride-Bonded SiC Pump Part / Impeller?

It’s a durable pump impeller made from silicon nitride bonded silicon carbide. This combo makes it super hard, wear-resistant, and perfect for tough slurry and chemical pumping.

How does the Si3N4-SiC impeller compare to high-chrome alloy impellers?

Our Si3N4-SiC impellers last longer, resist abrasion better, and handle corrosion tougher than high-chrome alloys—ideal for mining and chemical industries.

Can these pump parts handle high temperatures?

Yes, SiC bonded with silicon nitride tolerates high temperatures—up to around 1200°F—without losing strength or performance.

Are the parts customizable?

Absolutely. We offer OEM and ODM options with customized vane shapes, bore sizes, and integrated metal lining to fit your exact pump model.

What testing standards do the parts meet?

They’re tested according to ASTM wear standards and inspected with fluorescence penetrant methods. Plus, all manufacturing meets ISO 9001 quality controls.

How does the corrosion resistance hold up in acid leaching or FGD applications?

The ceramic Si3N4-SiC composition shows excellent corrosion resistance, making it ideal for aggressive chemical environments like acid leaching and flue gas desulfurization.

Is installation difficult?

Not at all. We provide detailed installation guides, torque specs, and even tutorial videos to make fitting your new impeller easy.

What kind of warranty comes with these pump parts?

We back our impellers with a solid warranty. Contact our support team for exact terms and any questions about claims or replacements.

Where can I buy Gotrays nitride-bonded SiC impellers in the US?

Gotrays offers local shipping across the United States, with stock ready for immediate shipment and volume pricing for larger orders.

How do I get technical support if I experience issues?

Our expert engineers are just a call or email away, ready to assist with technical questions or troubleshooting. Contact details are on our support page.

This FAQ is voice search optimized, so you can quickly find answers hands-free when you’re on the job site.

Related Gotrays Products and Resources

Explore our range of complementary products designed to enhance your pump system’s performance and durability. Alongside our nitride-bonded SiC pump parts and Si3N4-SiC impellers, we offer high-quality ceramic liners, pump shafts, and silicon nitride bonded SiC volute liners. These components work seamlessly with your existing gear, helping you cut downtime and boost output.

For easy reference, you can download detailed spec sheets, installation guides, and whitepapers directly from our site. These resources provide clear instructions, technical data, and industry insights to help you get the most out of your pump parts.

Stay connected with Gotrays for trusted, US-certified pump parts and expert support whenever you need it.

Ready to Upgrade Your Pump Parts

If you’re looking to boost your pump performance with durable, wear-resistant nitride-bonded SiC pump parts, Gotrays has you covered. Our Si3N4-SiC impellers deliver longer life, reduced downtime, and improved efficiency—perfect for tough industries like mining, power, and chemical processing.

Get Started Today

- Request a free quote

- Download the full spec sheet

- Contact our pump experts for a custom solution

Stay ahead with the best in abrasion-resistant pump components. Sign up for our newsletter to get the latest updates, technical tips, and exclusive offers straight to your inbox.

Reviews

There are no reviews yet.