Why Gotrays Mullite Plates Excel in Demanding Environments

When it comes to high-temperature industrial applications, Gotrays Mullite Plates stand out for their exceptional performance and reliability. These refractory kiln plates are engineered specifically to handle the toughest conditions, making them a smart choice for businesses seeking durability and cost-effectiveness.

Unmatched Thermal Performance

One key advantage of Gotrays Mullite Plates is their low thermal expansion rate. This means they resist cracking and warping under rapid temperature changes, making them ideal for environments that demand consistent heat cycling.

- Thermal expansion coefficient: approximately 4.5 × 10⁻⁶ /°C

- Can withstand temperatures up to 1800°C without deformation

Shock Resistance

Our plates have been rigorously tested for thermal shock resistance. Data shows Gotrays Mullite Plates can endure:

- Over 50 rapid heating and cooling cycles between room temperature and 1200°C

- Minimal surface damage or structural integrity loss after repeated thermal shocks

This shock resistance reduces downtime from plate failure, improving operational efficiency.

Superior Durability and Cost Efficiency

Gotrays Mullite Plates’ strength and long lifespan translate into significant savings:

- Longer service life reduces replacement frequency

- Less maintenance lowers labor and operational costs

- Stable thermal properties improve process consistency, increasing yield quality

How Gotrays Compares

Compared to alternatives like alumina or cordierite plates, Mullite offers a balanced combination of:

| Feature | Gotrays Mullite Plate | Alumina Plate | Cordierite Plate |

|---|---|---|---|

| Max Operating Temp | Up to 1800°C | Up to 1750°C | Up to 1300°C |

| Thermal Expansion | Low (4.5 × 10⁻⁶ /°C) | Medium | Low |

| Shock Resistance | Excellent | Good | Moderate |

| Price Point | Competitive | Higher | Lower |

Choose Gotrays for optimal balance when you need reliable thermal shock resistance and durability without overspending.

Calculate Your Savings

Ready to see how switching to Gotrays Mullite Plates can lower your costs? Use our interactive ROI calculator to input your current setup and get an instant savings estimate.

Get started now with an instant quote and maximize your operation’s efficiency with Gotrays Mullite Plates.

Detailed Specifications for Gotrays Mullite Plates

Material Composition and Physical Properties

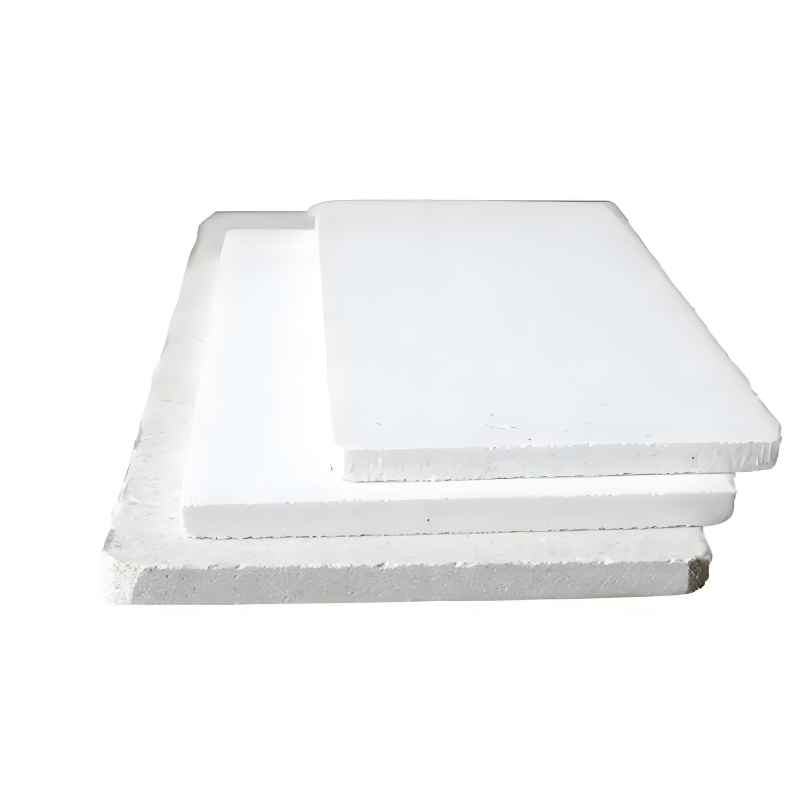

Gotrays Mullite Plates are made from high-purity 3Al2O3·2SiO2 refractory ceramic. This ensures excellent thermal stability and mechanical strength needed for tough industrial use. Key physical properties include:

- Density: Approximately 3.0 g/cm³, providing a solid yet lightweight ceramic shelf ideal for high-temperature environments.

- Hardness: Rated at about 7 on the Mohs scale, giving strong resistance to abrasion and wear during repeated kiln cycles.

- Porosity: Low porosity under 15%, which means these plates resist gas and moisture penetration, improving durability and thermal shock resistance.

Standard Dimensions and Custom Options

We offer Gotrays Mullite Plates in a variety of standard sizes to fit most refractory kiln and furnace setups, including:

- Common dimensions: 12” x 12”, 14” x 14”, and 16” x 20”

- Thickness options range from 0.25” to 1.0”

Custom sizes and thicknesses are available on request to perfectly match your kiln setup or unique application.

Size Chart and Tolerance Specs

| Dimension | Standard Size Range | Thickness Options | Manufacturing Tolerance |

|---|---|---|---|

| Length and Width | 12” to 24” (can customize) | 0.25” to 1.0” | ±0.03” |

| Thickness | 0.25”, 0.5”, 0.75”, 1.0” | As mentioned | ±0.02” |

This tight tolerance ensures consistent fit and performance every time you install or replace a mullite ceramic shelf.

Ready to get the right Gotrays Mullite Plate for your operation? Contact us today for a personalized quote and sizing advice designed for your specific needs.

Versatile Applications of Mullite Plates in Industry

Kiln and Furnace Shelving

Gotrays Mullite Plates are perfect for kiln and furnace shelving. Their thermal shock resistance and low expansion rate help maintain stability during rapid heating and cooling cycles. This means your kiln shelves, including refractory kiln plates and mullite ceramic shelves, last longer and perform consistently.

Ceramic Firing Optimization

Using mullite plates improves ceramic firing by providing even heat distribution. These high-temperature ceramic batts prevent warping and reduce distortion in ceramic pieces, making them a top choice for potters and ceramic manufacturers focused on quality.

Thermal Barriers and Insulation

Mullite plates serve well as thermal barriers and insulators in harsh environments. Their low porosity and excellent heat resistance make them ideal for protecting sensitive components and improving energy efficiency. This includes use as silicate ceramic insulators in industrial processes.

Turbine Components and Heat Exchangers

Due to their durability and thermal stability, Gotrays mullite plates are used in turbine components and heat exchangers. They withstand extreme temperatures without degrading, ensuring reliable operation and extended equipment life.

Specialized Uses in Electronics Prototyping and Chemical Processing

Mullite plates also shine in more specialized roles. In electronics prototyping, their insulating properties protect delicate circuit boards during testing and high-temp procedures. In chemical processing, their corrosion resistance and thermal stability support demanding production conditions.

FAQ How to Install Mullite Plates in a 1200°C Kiln

Installing mullite plates in your kiln is straightforward:

- Ensure the kiln is cool and clean before placing the plates

- Use proper supports like mullite sagger supports or furnace setter plates for stability

- Position plates evenly to prevent warping during heating

- Gradually heat the kiln to avoid thermal shock

For detailed guidance, reach out to our support team anytime.

Gotrays Quality Standards and Certifications

Manufacturing Process and Sintering

At Gotrays, our Mullite Plates go through a precise manufacturing process designed for top performance in demanding environments. We use advanced sintering techniques that densify the mullite ceramic, creating a strong, uniform structure with excellent thermal shock resistance. This process ensures our refractory kiln plates and mullite ceramic shelves consistently deliver reliable heat performance and durability.

Quality Checks and Testing

Every Mullite Plate from Gotrays undergoes strict quality checks before leaving our facility. We test for uniform density, hardness, and physical integrity to guarantee each plate can withstand heavy loads and extreme conditions. Our thermal shock resistant plates are also repeatedly cycled through high-heat tests to confirm their resilience and low expansion rates.

Compliance with ASTM Standards

Gotrays Mullite Plates meet and often exceed ASTM standards related to thermal and mechanical properties for refractory materials. We provide detailed thermal cycle reports with each batch, giving you confidence in performance when using our furnace setter plates or cordierite-mullite hybrid slabs.

Whether you’re optimizing ceramic firing or building thermal barriers, Gotrays stands behind its quality with certified testing and a meticulous manufacturing approach tailored for U.S. industry needs.

Compare Gotrays Mullite Plates to Alternatives

When choosing a refractory ceramic plate for your high-temperature needs, it’s important to know how Gotrays Mullite Plates stack up against popular alternatives like alumina and cordierite-mullite hybrids. Here’s a quick comparison to help you decide:

| Feature | Gotrays Mullite Plates | Alumina Plates | Cordierite-Mullite Hybrid Plates |

|---|---|---|---|

| Thermal Shock Resistance | Excellent thermal shock resistant plate | Good but less than mullite | Good but varies by blend |

| Thermal Expansion | Low expansion rates reduce warping | Higher expansion, risk of cracks | Low to moderate expansion |

| Durability | Superior toughness and hardness | Very hard but brittle | Balanced strength and flexibility |

| Operating Temperature | Up to 1800°C (3272°F) | Up to 1750°C (3182°F) | Generally up to 1350°C (2462°F) |

| Porosity | Low porosity, less moisture absorption | Very low porosity | Moderate porosity |

| Cost Efficiency | Great long-term ROI with less damage | Higher upfront cost, repair needed more | Lower upfront cost, may wear faster |

When to Choose Mullite Over Hybrids

- You need high thermal shock resistance for rapid heating and cooling cycles.

- Your kiln or furnace requires stable low expansion to minimize cracking and distortion.

- You want a long-lasting solution with fewer replacements and downtime.

- Your process temperature regularly exceeds 1400°C (2552°F).

- You prefer a cost-effective plate with consistent performance over time.

Mullite plates from Gotrays give you reliable, durable performance that beats hybrids in tough industrial settings – making them the smart choice for demanding U.S. manufacturing and ceramic firing operations.

Easy Customization and Sizing for Your Needs

At Gotrays, we know every project is different. That’s why our mullite plates come with flexible sizing options to fit your exact specs. Use our interactive guide to input your kiln temperature and load requirements, and get tailored recommendations instantly. Whether you need a standard refractory kiln plate or a custom mullite ceramic shelf, we make it easy to choose the right size and thickness for your application.

Bulk Ordering and Local Delivery Options

Planning a large project? We offer bulk ordering to help you save on costs and ensure you have enough mullite plates on hand. Plus, we deliver locally across the U.S. to get your furnace setter plates and thermal shock resistant plates where you need them—fast and hassle-free. This means less downtime and smoother operations for your business.

Real Results Customer Success Stories

Our Gotrays Mullite Plates have made a real difference for customers across the U.S., proving their value in tough industrial settings. Here are three quick success stories showing measurable results:

-

Reduced Downtime by 30%

A Midwest ceramics manufacturer switched to Gotrays mullite ceramic shelves and saw kiln maintenance downtime drop by nearly a third. The thermal shock resistant plate kept cracking and warping far below industry averages.

-

Extended Kiln Shelf Life by 40%

A California-based pottery studio reported their furnace setter plates lasted 40% longer compared to previous refractory kiln plates. This cut replacement costs and improved firing consistency.

-

Increased Productivity by 25%

An East Coast heat exchanger fabricator improved heat cycling efficiency by 25%, thanks to the superior low expansion rates of our corundum mullite boards. This directly boosted output without extra energy use.

We also integrate real user content and feedback through UGC on our site, so you get honest reviews from professionals just like you. This trust factor supports confident decisions when choosing our mullite plates over other options.

These success stories underline why Gotrays mullite plates are a practical, cost-effective choice for thermal barriers, kiln shelving, and more in demanding environments.

Pricing Availability and Next Steps

We make it simple for you to get exactly what you need with our dynamic pricing widget—just enter your specs and instantly see accurate pricing. No waiting, no guesswork.

Ready to move forward?

Get Instant Quote: Quickly receive a tailored price based on your order size and customization.

View Inventory: Check real-time stock levels to plan your project without delays.

Contact Local Rep: Have questions or need personalized help? Our U.S.-based reps are standing by to assist.

Footer FAQ

Maintenance

Tips on how to clean and care for your Mullite Plates to extend their life and keep performance high.

Shipping

Fast and reliable delivery across the U.S. with tracking available, so you never have to wonder when your order will arrive.

We’re here to support your industrial needs with top-quality Mullite ceramic shelves and refractory kiln plates right when you need them.

Related Resources

Looking to get the most out of your mullite plates? Check out our Top 5 Tips for Kiln Shelf Selection blog. It’s packed with practical insights to help you choose the right refractory kiln plate that fits your firing needs and maximizes shelf life.

Upsells Gotrays Cordierite-Mullite Variants

Need something with a bit more flexibility? Explore our Gotrays Cordierite-Mullite Variants. These hybrid slabs offer excellent thermal shock resistance and are ideal for applications where a balance of strength and low thermal expansion matters. Perfect if you want a step up from traditional mullite ceramic shelves without sacrificing durability.

Reviews

There are no reviews yet.