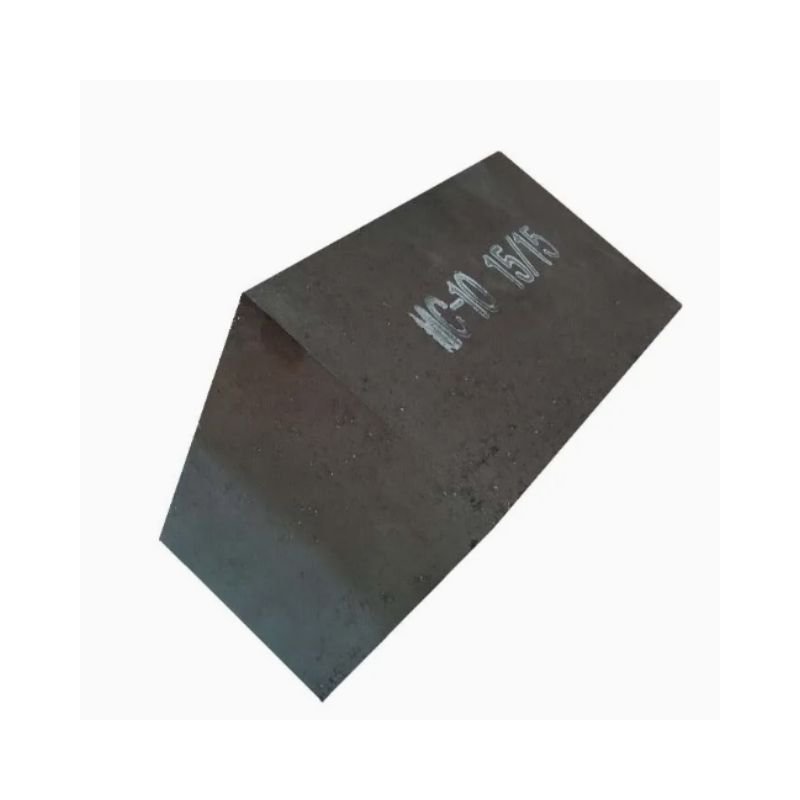

Magnesia Carbon Brick Product Overview

Are you looking for a reliable, high-performance refractory solution for your steelmaking operations? Gotrays Magnesia Carbon Brick is designed to meet the toughest demands in the US steel industry. Our MgO C refractory bricks combine exceptional thermal shock resistance, slag corrosion protection, and mechanical strength to keep your furnaces, converters, and ladles running longer and smoother.

Built to endure extreme temperatures and harsh environments, these magnesia graphite bricks reduce downtime and maintenance costs. Whether you’re upgrading your converter linings, tackling EAF hot spots, or reinforcing ladle slag lines, Gotrays Magnesia Carbon Bricks deliver consistent performance you can count on.

Ready to improve your refractory lifecycle and cut operational risks? Contact us today for a fast quote and expert guidance on how Gotrays MgO C bricks can empower your steelmaking process.

Technical Specifications of Magnesia Carbon Brick

Our Magnesia-Carbon bricks are engineered for tough industrial use with a balanced blend of materials to deliver superior durability. Here’s what you need to know about their specs:

Material Composition

- High-purity fused magnesia (MgO) combined with carbon (graphite)

- Added antioxidants to enhance oxidation resistance

- Special binding agents for improved strength and stability

Bulk Density

- Typically ranges between 3.3 to 3.5 g/cm³

- Ensures a dense, robust brick for long-lasting performance

Porosity

- Low porosity, usually below 15%

- Limits slag penetration and helps maintain mechanical strength

Crushing Strength

- High crushing strength exceeding 30 MPa

- Designed to withstand mechanical stress in converters, ladles, and electric arc furnace hot spots

Chemical Analysis

- MgO content above 90% for excellent slag resistance

- Carbon content usually between 8% to 15% to improve thermal shock and oxidation resistance

- Trace elements carefully controlled to meet industry standards

Standard Shapes and Sizes

- Common shapes include bricks, blocks, and precast forms

- Sizes available in standard and custom dimensions to fit specific applications

- Tailored sizing available for converter linings, ladle slag lines, and EAF hot spot bricks

These Magnesia Carbon Bricks are built with a strong focus on durability and performance to suit the demanding conditions found in steelmaking and non-ferrous industries across the US market.

Key Properties and Performance Benefits

Magnesia-Carbon Bricks offer outstanding performance where heat and wear meet. They handle extreme high temperatures with ease, making them perfect for steelmaking and other heavy industries. Their high temperature resistance means they won’t break down or lose strength even in the hottest parts of your furnace or converter lining.

These bricks excel in slag corrosion resistance, standing firm against aggressive slags that can eat away other materials. This means longer life for your lining and fewer shutdowns for repairs.

Thermal shock stability is another major plus. Sudden temperature changes happen a lot in steel plants, but these bricks resist cracking and damage, helping you avoid costly downtime.

Mechanical strength is solid too. Magnesia-carbon bricks can handle heavy loads and physical abuse during installation and operation without crumbling or wearing out quickly.

Plus, these bricks are designed with environmental considerations in mind. Their durability reduces waste and replacement frequency, supporting greener steel production practices.

In , these bricks combine:

- Heat tolerance up to 3200°F (1760°C)

- Resistance to slag attack and corrosion

- Strong thermal shock resistance for rapid cooling and heating

- High mechanical strength for tough conditions

- Environmental benefits through longer service life and sustainability

These properties make magnesia-carbon bricks the go-to choice for reliable, high-performance refractory needs in the U.S. steel industry and related sectors.

Applications in Industry

Magnesia-Carbon Bricks are tough enough for the hardest jobs in steelmaking and other heavy industries. Here’s where they really shine:

- Converter Linings: They protect the lining of basic oxygen furnaces (BOF) from extreme temperatures and chemical attack, extending the life of your converters.

- EAF Hot Spots: Electric arc furnaces generate intense heat in certain zones. Our magnesia graphite bricks handle these hot spots without breaking down, reducing downtime and repair costs.

- Ladle Slag Lines: In ladle linings, slag resistance is key. These bricks resist slag penetration and erosion, keeping your ladle walls strong during steel refining.

- Refining Furnaces: Whether reheating or refining, these bricks withstand prolonged exposure to high temperatures and corrosive slags.

- Non-Ferrous Smelting: When working with metals like aluminum and copper, magnesia carbon bricks offer excellent chemical and thermal stability.

- Vanadium Extraction: The process involves harsh slags and thermal cycles. Our bricks stand up to these conditions, ensuring operational consistency.

Case Study Teaser

We’ve helped US-based steel plants cut maintenance costs by up to 30% using our magnesia carbon bricks in converter linings. Stay tuned for the full story on how switching to our product made a real difference on the shop floor.

These bricks are a reliable choice to boost uptime and reduce repair frequency wherever intense heat, slag attack, or thermal shock is a problem.

Manufacturing Process Transparency

At Gotrays, we’re upfront about how we make our Magnesia-Carbon Bricks because quality starts with transparency. Here’s how we ensure every brick meets top standards:

- Raw Material Selection: We start by sourcing the highest-grade fused magnesia and high-purity carbon materials. This ensures durability and strong resistance to slag and thermal shock—key for U.S. steelmakers facing tough conditions.

- Mixing: Our materials are carefully blended to get the perfect balance of chemical composition and physical properties. This step controls bulk density and porosity for consistent performance.

- Molding: The mixed batch is shaped into standard sizes or customized forms, using precise molding techniques to avoid weak points.

- Curing: Once molded, bricks go through controlled curing to bond the material firmly, improving crushing strength and thermal stability.

- Quality Assurance Testing: Every batch is tested for bulk density, porosity, crushing strength, and chemical makeup before it leaves the factory. We also verify resistance to oxidation and slag penetration.

This process transparency means you get Magnesia Carbon Bricks built to last, designed for the demanding US market, and backed by reliable quality checks every step of the way.

Comparison with Alternatives

When it comes to Magnesia-Carbon Bricks, you have options, but not all are created equal. Here’s how Gotrays’ MgO C refractory bricks stack up against Alumina Magnesia Carbon (AMC) bricks and traditional magnesia bricks.

Magnesia Carbon Bricks vs Alumina Magnesia Carbon Bricks

| Feature | Magnesia Carbon Bricks (MgO-C) | Alumina Magnesia Carbon Bricks (AMC) |

|---|---|---|

| Thermal Shock Resistance | Excellent for rapid temp changes | Good but slightly less stable |

| Slag Corrosion Resistance | Superior against basic and acidic slags | Good resistance but less durable in some slags |

| Mechanical Strength | High mechanical strength under stress | Strong but can degrade faster under impact |

| Oxidation Resistance | Carbon addition offers antioxidant effects | More prone to oxidation without additives |

| Cost Efficiency | More cost-effective for heavy-duty use | Often pricier due to alumina content |

| Suitability | Best for steel converter linings and ladle slag lines | Good for applications needing alumina’s properties |

Magnesia Carbon Bricks vs Traditional Magnesia Bricks

| Feature | Magnesia Carbon Bricks | Traditional Magnesia Bricks |

|---|---|---|

| Thermal Shock Resistance | Much higher thanks to carbon content | Lower, cracks more under rapid changes |

| Slag Resistance | Outstanding, especially against wear and slag attack | Moderate, prone to slag penetration |

| Mechanical Strength | Superior strength under harsh conditions | Weaker, breaks down faster |

| Durability | Long service life reducing maintenance | Shorter lifespan, more frequent replacements |

| Environmental Impact | Improved with antioxidant additives and recycling focus | Higher energy use, less eco-friendly |

Benefits of Gotrays Magnesia Carbon Bricks

- Better thermal shock stability reduces downtime and maintenance costs.

- Enhanced slag corrosion resistance extends brick life in harsh steelmaking environments.

- Strong mechanical properties handle the toughest industrial stresses.

- More cost-effective over time compared to AMC or traditional bricks.

- Tailored for the needs of U.S. steel plants, ensuring reliability and performance.

Choosing Gotrays Magnesia Carbon Bricks means investing in quality that lasts while keeping your operations efficient and your costs predictable.

Pricing Availability and Customization

At Gotrays, we understand that every steel plant and foundry in the US has unique needs. That’s why our magnesia-carbon bricks come with flexible pricing options tailored for different order sizes. Whether you need a small batch for testing or bulk orders for large projects, we offer tiered pricing to keep costs efficient as you scale up.

We know timing is critical in your operations. Our standard lead time is designed to meet tight schedules, with expedited options available to keep your production on track. Plus, with our reliable global shipping, you can count on your magnesia graphite bricks arriving on time, no matter where you’re located.

Customization is a big part of what makes Gotrays bricks stand out. We offer tailored formulations to match your specific requirements—whether it’s enhanced slag resistance, improved thermal shock durability, or optimized bulk density. Just let our team know your needs, and we’ll develop the perfect magnesia carbon refractory solution for your facility.

Key benefits:

- Tiered pricing for cost savings on larger orders

- Fast and reliable lead times

- Worldwide shipping with local US support

- Custom formulations for your exact application

Get in touch to receive a fast quote and find out how we can tailor our magnesia-carbon bricks to fit your plant’s needs.

FAQs and Support Resources

Common Questions About Magnesia-Carbon Bricks

What are magnesia-carbon bricks used for?

They’re mainly for high heat areas like steel converter linings, electric arc furnace (EAF) hot spots, ladle slag lines, and refining furnaces. They resist slag corrosion and thermal shock really well.

How do Gotrays magnesia-carbon bricks compare to others?

Our bricks offer superior thermal shock resistance, better slag penetration protection, and longer service life thanks to our enhanced formulation and quality control.

Can I get custom sizes or shapes?

Yes, we provide tailored shapes and sizes to fit your specific project needs, plus we offer bulk orders with competitive pricing.

What’s the lead time for orders?

Typically, we ship within 2-3 weeks depending on order size and customization. Expedited shipping is available for urgent jobs.

Are Gotrays bricks eco-friendly?

Absolutely. We use recycled materials where possible and focus on sustainable manufacturing, helping you reduce your environmental footprint.

Helpful Downloadables

- Detailed specification sheets

- Installation and maintenance guides

- Case studies showcasing our bricks in action

- Safety data sheets (SDS) for handling and use

Need Expert Support?

Have more questions or need technical help?

- Contact our steel industry experts via email or phone.

- Schedule a free consultation to discuss your project needs.

- Access online chat support during business hours.

We’re here to make your refractory decisions easy and effective. Reach out anytime!

Why Choose Gotrays for Magnesia Carbon Bricks

At Gotrays, we understand the demands of U.S. steelmakers and foundries. Our Magnesia Carbon Bricks are designed for lasting performance in tough environments like converter linings, EAF hot spots, ladle slag lines, and more. We focus on quality, reliability, and supporting your operation with the best materials.

What Our Customers Say

“Gotrays’ MgO C bricks have transformed our furnace uptime. They hold up against thermal shock and slag corrosion like no other.” — Midwest Steelworks

“Fast delivery and excellent technical support make Gotrays our go-to supplier for magnesia graphite bricks.” — Texas Foundry Solutions

“We switched to Gotrays’ fused magnesia carbon blocks for our ladle linings and saw major improvements in durability.” — Ohio Steel Production

Ready to Upgrade Your Refractories?

- Get a personalized quote for your project

- Ask about custom sizes and formulations

- Benefit from fast shipping across the U.S.

Contact Gotrays today and experience the difference with premium MgO C refractory bricks built for America’s steel industry.

What Are Magnesia Carbon Bricks Essential Guide for Steelmakers

Magnesia Carbon Bricks, also called MgO C refractory bricks, are a tough mix of magnesia (MgO) and carbon materials like graphite. They’re built to handle the extreme heat and harsh conditions inside steelmaking furnaces and converters. The magnesia provides resistance to slag and high temperatures, while the carbon adds strength and thermal shock resistance.

For steelmakers, these bricks are crucial because they protect equipment from wear, extend furnace life, and keep production running smoothly. Their unique composition makes them ideal for lining converter vessels, electric arc furnaces (EAF), ladle slag lines, and other high-demand areas.

Understanding the makeup and performance of Magnesia Carbon Bricks helps steel plants optimize their refractory choices and reduce downtime. For a closer look at how these bricks work and where they fit in your operation, check out our detailed guide on Magnesia Carbon Bricks for Steelmakers.

Key Properties of Gotrays Magnesia Carbon Bricks Engineered for Extreme Conditions

Gotrays Magnesia Carbon Bricks are built tough to handle the harshest conditions in steelmaking and metal processing. Here’s what makes them stand out for U.S. steel plants and foundries:

-

Thermal Shock Resistance

These bricks can handle rapid temperature changes without cracking. That means less downtime and longer lining life in converters and EAF hot spots.

-

Slag Penetration Resistance

Gotrays MgO C bricks fight off slag attack, reducing wear and maintaining structural integrity in ladle slag lines and refining furnaces.

-

Oxidation Protection

Enhanced carbon content acts as an antioxidant, protecting bricks from oxygen damage, extending service life even in high-oxygen spaces.

-

Mechanical Strength

They deliver impressive crushing strength to stand up under heavy loads and mechanical stress typical in steel converter linings.

-

Environmental Stability

These bricks minimize dust and particle release, supporting cleaner air in your plant – a growing priority in U.S. manufacturing.

Why It Matters Locally

For U.S. steel operations, Gotrays bricks improve uptime and reduce replacement costs. Their top-tier resistance to thermal and chemical stresses translates to fewer shutdowns and better productivity, directly impacting your bottom line. Plus, the strong environmental profile aligns with U.S. regulations and green manufacturing goals.

Check out the infographic below for a clear view of how these properties work together to keep your plant running strong.

Applications Where Gotrays MgO C Bricks Excel

Gotrays Magnesia-Carbon Bricks are built to handle some of the toughest jobs in the steel and metal industries across the U.S. Here’s where they stand out:

-

BOF Converter Linings

Our MgO C bricks offer excellent resistance to thermal shock and slag attack in Basic Oxygen Furnace (BOF) converter linings, helping plants run smoothly with less downtime.

-

EAF Hot Spot Linings

Electric Arc Furnace areas with intense heat and slag splashing are no match for our slag-resistant carbon bricks, providing durability where it’s needed most.

-

Ladle Slag Lines

In ladles, Gotrays Magnesia Carbon bricks protect against harsh slag corrosion and temperature swings, extending lining life and improving performance.

-

Vanadium Extraction Furnaces

The high-performance characteristics of our bricks are ideal for the demanding conditions of vanadium smelting and other non-ferrous refining applications.

Real-World Case Studies

U.S. steelmakers have reported fewer shutdowns and lower maintenance costs after switching to Gotrays MgO C bricks. Specific examples include:

- A Midwest steel plant that saw a 30% increase in lining life during converter operations.

- An EAF operator in Texas noted improved thermal shock resistance and reduced brick breakage in hot spot areas.

- A vanadium extraction facility in Nevada extended their furnace campaign time by 20%, thanks to Gotrays brick quality.

Frequently Asked Questions

- How do these bricks handle repeated thermal cycling?

They’re engineered to resist cracking and spalling, even in extreme temperature changes. - Can Gotrays bricks be customized for unique furnace designs?

Yes, we offer bespoke formulations and sizes to fit varying industrial needs. - Are these bricks environmentally friendly?

Yes, our products include recycled content and support green steel initiatives.

For more info or specific inquiries, check our detailed FAQ section or reach out to our experts anytime.

Gotrays vs Competitors Why Our Magnesia Carbon Refractory Stands Out

When it comes to magnesia-carbon bricks, Gotrays offers clear advantages over other brands on the market. Our focus is on quality, durability, and sustainability—all crucial for the demanding U.S. steel and metal industries.

What Makes Gotrays Different

-

Superior Thermal Shock Resistance

Our MgO C refractory bricks handle rapid temperature changes better, reducing crack risks and extending service life.

-

Enhanced Slag Corrosion Protection

We use a special blend of magnesia and graphite, keeping your linings safe from harsh slag attacks longer than typical magnesia graphite bricks.

-

Higher Mechanical Strength

Gotrays bricks maintain strength even under extreme pressure and wear, perfect for EAF hot spots and converter linings.

-

Eco-Friendly Manufacturing

We incorporate recycled materials and optimize energy use during production, making our bricks a greener choice.

-

Custom Formulations

Based on your needs, we tailor the brick composition—whether for ladle lining refractories or vanadium extraction—offering flexibility that many competitors don’t.

Comparison Table Gotrays vs Competitors

| Feature | Gotrays MgO C Bricks | Typical Competitor Bricks |

|---|---|---|

| Thermal Shock Resistance | High | Medium to Low |

| Slag Corrosion Resistance | Superior | Average |

| Mechanical Strength | Excellent | Good |

| Sustainability | Uses recycled content | Minimal focus |

| Customization Options | Wide variety | Limited |

| Lead Time | Fast, local U.S. availability | Longer, international shipping |

Sustainability Benefits for Your Operation

Choosing Gotrays doesn’t just improve your lining performance—it supports your commitment to greener steelmaking. Our bricks help reduce waste and energy consumption, aligning with U.S. industry goals for sustainable manufacturing.

By picking Gotrays magnesia-carbon bricks, you get reliability, performance, and a partner who understands the unique needs of U.S. steel producers. Reach out today to learn how we can upgrade your refractory linings.

Technical Specifications and Custom Options

At Gotrays, our Magnesia-Carbon Bricks are designed with precise technical specifications to meet the demanding needs of the U.S. steel and foundry industries. Here’s a quick look at the key specs:

| Specification | Typical Values |

|---|---|

| Material Composition | MgO 85-92%, Carbon 8-15% |

| Bulk Density | 3.3 – 3.5 g/cm³ |

| Porosity | 12 – 15% |

| Crushing Strength | ≥ 30 MPa |

| Thermal Conductivity | 5 – 7 W/mK |

| Maximum Service Temp | 1700°C (3092°F) |

| Chemical Resistance | Excellent against slag & alkali |

Customization Options

We understand that every job is unique, so we offer:

- Size and Shape Flexibility: Standard bricks, wedges, and custom profiles adapted to your equipment.

- Tailored Formulations: Adjusted carbon content or additives to match specific slag chemistries or thermal demands.

- Bulk Orders and Samples: Fast turnaround for orders big and small, with sample packs available for testing.

Get the Perfect Fit for Your Project

Use our customization form on the Gotrays website to specify your requirements. Whether you need a special size for an EAF hot spot or an anti-oxidant enhanced blend, we are equipped to deliver quickly and reliably across the United States.

Boost your operation’s efficiency by selecting Magnesia-Carbon Bricks engineered right here for U.S. steelmakers.

Installation Maintenance and Longevity Tips

Installing and maintaining magnesia-carbon bricks right means better performance and longer life for your refractory lining. Here’s a simple step-by-step guide to help you get the most out of your MgO C refractory bricks.

Installation Tips

- Preheat the area where bricks will be placed. This prevents thermal shock right from the start.

- Check for clean surfaces before setting bricks to ensure solid bonding and no gaps.

- Use recommended bonding materials to secure the magnesia graphite bricks firmly.

- Avoid rapid cooling or heating during installation to prevent cracks.

- Follow manufacturer guidelines exactly for brick orientation and jointing.

Maintenance Tips

- Inspect regularly for cracks or signs of slag penetration—early fixes save costly downtime.

- Clean slag buildup promptly to avoid damaging the refractory surface.

- Monitor hot spots closely, especially in EAF linings and converter areas.

- Maintain proper cooling systems to reduce thermal stress and extend brick life.

- Replace damaged bricks immediately to prevent domino failures.

Longevity Best Practices

- Use carbon-enhanced protective coatings if recommended to reduce oxidation.

- Implement routine thermal cycling protocols to minimize stress on bricks.

- Ensure consistent operating temperatures without sudden spikes.

- Train your team on proper handling and inspections to catch issues early.

For a visual walkthrough and more detailed instructions, check out our installation and maintenance video guide below. It’s designed to help local steel plants and foundries in the US maximize their refractory investments.

[Embed maintenance video here]

Pricing Shipping and Bulk Orders

At Gotrays, we keep our pricing simple and transparent. Whether you need magnesia-carbon bricks for a small repair or a large-scale project, we offer tiered pricing that fits your budget. The more you order, the better the deal — making bulk orders cost-effective for steelmakers across the U.S.

Fast Quotes and Easy Ordering

- Get a quick, no-hassle quote directly from our website or by contacting our sales team.

- We respond promptly so your project stays on schedule.

Local Delivery and Global Shipping

- We prioritize local delivery for faster turnaround times across major U.S. steelmaking regions.

- For international needs, our global shipping network ensures your magnesia graphite bricks arrive on time and intact.

Bulk Discounts and Custom Options

- Large orders unlock exclusive bulk discounts to save you more.

- Need tailored formulations or custom sizes? We handle customization without adding hidden fees.

Ready to upgrade your refractory materials? Contact Gotrays today for a fast quote and seamless delivery on premium magnesia-carbon bricks designed for your steel operations.

Sustainability and Innovation in Gotrays MgO C Bricks

At Gotrays, we’re committed to building magnesia-carbon bricks that aren’t just tough—they’re eco-friendly too. Our MgO C refractory bricks include recycled content, helping reduce waste and lower your environmental impact. This fits perfectly with the growing demand for green steel production across the U.S.

We focus on innovation to future-proof your operations. Our bricks are designed for durability, meaning fewer replacements and less material consumption over time. That cuts down on downtime and costs while supporting sustainable manufacturing practices.

What makes Gotrays MgO C bricks stand out environmentally:

- Use of recycled raw materials to reduce landfill impact

- Energy-efficient manufacturing processes

- Low emissions during production and installation

- Supports green steel initiatives through longer service life

By choosing Gotrays, you’re not only getting reliable high-performance magnesia graphite bricks but also contributing to a cleaner, greener steel industry. This balance of performance and sustainability positions our products as smart solutions for U.S. steelmakers aiming for eco-conscious growth.

Frequently Asked Questions About Magnesia Carbon Bricks

What are magnesia carbon bricks used for

Magnesia carbon bricks, also known as MgO C refractory bricks, are mainly used in steelmaking, especially for lining converters, electric arc furnaces (EAF), ladles, and refining furnaces. They handle high temperatures and resist slag corrosion effectively.

How do magnesia graphite bricks differ from magnesia carbon bricks

Both terms often refer to the same type of brick. The main components are magnesia (MgO) and carbon, often graphite. These bricks combine high thermal resistance with slag corrosion protection.

Can magnesia carbon bricks handle thermal shock

Yes, one key property is superior thermal shock resistance. This makes them ideal for areas like EAF hot spots, where temperatures change rapidly.

Are these bricks environmentally friendly

Gotrays’ magnesia carbon bricks include antioxidant additives and recycled materials to minimize environmental impact. They also contribute to longer lining life, reducing waste from frequent replacements.

How customizable are these bricks

We offer tailored formulations and standard shapes and sizes, with options for custom dimensions to fit your specific furnace or ladle needs.

What’s the typical lead time for orders

Local US customers typically receive orders within 2 to 4 weeks, depending on volume and customization. Bulk orders and ongoing supply contracts can get preferential scheduling.

How do Gotrays’ MgO C bricks compare with alumina magnesia carbon alternatives

Gotrays bricks provide improved slag resistance, thermal stability, and longer service life, making them a cost-effective, durable choice for steelmakers looking for reliable furnace linings.

Where can I find technical data sheets or installation guides

All product information, including technical specs and maintenance tips, are available for download on our website. We also offer video guides and expert support if needed.

Who can I contact for support or custom solutions

Our expert team is available via phone and email for technical questions, custom orders, and ongoing support. Don’t hesitate to reach out for personalized assistance.

We use structured Q&A and schema markup to help your search for magnesia carbon brick info be easier and faster. If you want detailed answers on anything not covered here, contact us directly.

Contact Gotrays Your Trusted Magnesia Carbon Brick Partner

Need reliable magnesia-carbon bricks for your steelmaking or industrial needs? Get in touch with Gotrays today. We’re here to help you find the right MgO C refractory bricks that match your application perfectly.

Reach out easily:

Contact form: Visit our website to submit your questions or project details anytime.

Phone: Call us directly for quick answers and expert advice.

Email: Send your inquiries and get prompt support from our team.

What our customers say:

“Gotrays magnesia graphite bricks helped us improve lining life and cut downtime—highly recommend.” – Midwest Steel Plant

“Excellent guidance and fast shipping kept our EAF running smooth.” – Ohio Foundry

Partner with Gotrays for high-performance, slag-resistant carbon bricks designed for the American market. Let’s build success together.

Reviews

There are no reviews yet.