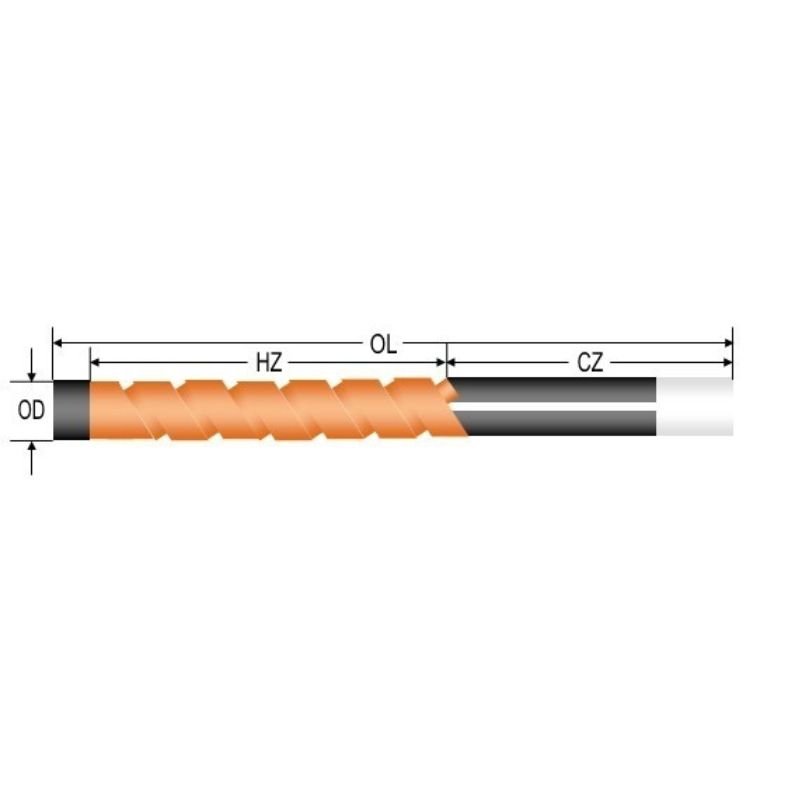

Double-spiral Silicon Carbide Heating Element SGR-500 by ThermoHeat

Experience superior heating performance with the ThermoHeat SGR-500 Double-spiral Silicon Carbide Heating Element. Designed for industrial high temperature applications, this element features a unique double spiral groove for even heat distribution and long-lasting durability.

![High resolution image of SGR-500 element showing spiral design and terminals]

View in 360° to explore every detail of the spiral design and connection terminals.

Key Highlights

- Maximum operating temperature up to 1650°C (3000°F)

- Exceptional lifespan with high density, reaction bonded SiC material

- Energy savings through uniform heat distribution and reduced thermal losses

Product Overview

Our Double-spiral Silicon Carbide Heating Element features a unique double spiral hot zone that delivers even heat distribution. Designed with one-end electrical connections, this simplifies installation and maintenance. Made from reaction bonded SiC, it offers excellent thermal shock resistance and long-lasting durability in extreme high-temperature environments.

Watch our quick video demo to see how easily this SiC heater installs in a kiln, ensuring fast setup and reliable performance.

Ideal for industries like metallurgy, ceramics, and glass melting, this silicon carbide heater suits any high-temperature furnace or kiln application where precision and energy efficiency matter.

Key Features and Benefits

- Uniform heat distribution with double spiral groove design

- High thermal shock resistance for longer life

- Excellent oxidation tolerance in harsh environments

- Easy access with single-plane terminal connections

| Feature | Benefit |

|---|---|

| High-density reaction bonded SiC | Reduced downtime thanks to fewer failures |

| Double groove hot zone | More even heating, less hot spots |

| Oxidation-resistant surface | Longer element lifespan in air or kiln atmospheres |

| Single-end connection | Simplified installation and maintenance |

Our double-spiral silicon carbide heating element combines proven durability with efficient heat control — perfect for industrial furnaces and high-temp kilns across the U.S. market.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Reaction bonded silicon carbide (SiC) |

| Density | High density for durability |

| Maximum Temperature | Up to 1600°C (2912°F) |

| Diameter Range | 10 mm to 30 mm |

| Hot Zone Length | 150 mm to 600 mm |

| Resistance | Customized to your wattage needs |

| Voltage | Compatible with 120V to 480V setups |

Download the full Double-spiral Silicon Carbide Heating Element spec sheet here for detailed info, including exact measurements and electrical options.

Applications

Our Double-spiral Silicon Carbide Heating Element is built for tough industrial conditions and precise heating needs. It works great in:

- Industrial Furnaces for metal processing and heat treatment

- Sintering Kilns where consistent high heat is a must

- Non-Ferrous Melting like aluminum, copper, and other metals

- Lab Ovens requiring rapid, uniform heating with strict temperature control

These heating elements deliver reliable performance, reducing downtime and maintenance costs across these applications.

Case Study Preview

One of our clients in ceramic production saw a noticeable drop in energy expenses using our double spiral SiC elements. The uniform heat helped cut cycles short and improve product quality, leading to significant savings long-term.

Ready to learn how it can work for your operation? Reach out for details!

Installation and Maintenance Guide

Step by Step Installation

-

Horizontal Mounting

Secure the double-spiral silicon carbide heating element in a clean, dry position. Ensure terminals are accessible for wiring. Use proper clamps to avoid stress on the element.

-

Vertical Mounting

Position the heater so the spiral grooves are vertical. Check for even support along the length to prevent bending. Leave space for thermal expansion.

-

Expansion Allowances

Silicon carbide expands when heated. Allow at least 3-5% length clearance in mounting to prevent cracking or warping during operation.

Maintenance Tips

-

Resistance Aging

Monitor element resistance regularly. A rising resistance typically means aging or damage. Track baseline resistance after installation for comparison.

-

Clean Atmosphere

Keep the furnace atmosphere clean and free of contaminants. Avoid exposure to moisture or debris which can accelerate element degradation.

-

Regular Inspection

Look for signs of oxidation or cracking. Replace elements at the first sign of wear to avoid downtime.

FAQ

How to Calculate Element Resistance

Resistance depends on element length, cross-section, and material properties. Use the formula:

R = ρ x (L / A)

Where R = resistance, ρ = resistivity of SiC, L = length, A = cross-sectional area. For exact specs, refer to the technical sheet or ask our team.

Is this Element Compatible With Kanthal Furnaces

Yes, the double-spiral silicon carbide element works well with most Kanthal-type industrial furnaces. Always check voltage and current specs before installation.

Customization Options

We understand every project is unique, so our Double-spiral Silicon Carbide Heating Element comes with tailored options to fit your exact needs. Whether you need custom sizing, offset hot zones for uneven heating, or split designs for easier installation, we’ve got you covered. Just fill out our quick form to get started on a solution that matches your furnace specs perfectly.

Compare Your Options

| Feature | Double-spiral SiC Element | Single Spiral SiC Element | U Type Element |

|---|---|---|---|

| Heat Distribution | More uniform with double groove | Less uniform, single groove | Limited uniformity |

| Thermal Shock Resistance | High | Moderate | Moderate |

| Installation Ease | Single plane access | Single plane access | Requires more space |

| Energy Efficiency | Higher due to better coverage | Moderate | Lower |

| Lifespan | Longer due to balanced heating | Shorter due to hot spots | Shortest due to design |

Choosing a double-spiral element gives you a reliable, energy-saving edge that’s hard to beat compared to single spiral or U type alternatives. If you want to explore custom tweaks or see which design fits your needs best, contact us for guidance.

Related Products and Accessories

Explore our range of related products designed to complement your Double-spiral Silicon Carbide Heating Element.

-

Gotrays Single Spiral SiC MoSi2 Elements

Ideal for applications needing precise heating control with single spiral design.

-

Ceramic Insulators

High-quality insulators that ensure safe and stable operation in your high-temperature setups.

-

Starter Kits

Bundles including 10 elements and mounting clamps to get your furnace running right away.

These accessories are perfect for upgrading or maintaining your industrial furnace, kiln, or oven with reliable, heavy-duty parts made for the demands of U.S. manufacturing and lab operations.

Customer Reviews and Testimonials

Our Double-spiral Silicon Carbide Heating Element gets top marks from verified buyers across the U.S. Users appreciate its reliable performance in high temperature operations with zero element failures reported.

What customers are saying:

“Consistently delivers even heat, no downtime—perfect for our furnace.”

“Lasts longer than any other SiC element we’ve used. A real cost saver.”

“Installation was simple, and the double spiral design really makes a difference.”

Star Ratings:

⭐️⭐️⭐️⭐️⭐️ – Rated highly for durability and energy savings.

Buyers value the high density reaction bonded SiC and the efficient double groove hot zone that keeps their industrial furnaces running smoothly, batch after batch.

Experience the same dependable heating solution trusted by professionals in ceramics, metallurgy, and glass melting industries nationwide.

Pricing and Contact

We offer flexible pricing tiers with volume discounts to fit your project size and budget. Whether you need one Double-spiral Silicon Carbide Heating Element or a full production run, we’ve got you covered.

Ready to get started?

- Contact Sales for personalized quotes

- Live Chat for quick answers

- Request a Free Sample to test before you buy

Our products meet strict quality standards including ISO and RoHS certifications. Plus, we ship worldwide, so no matter where you are in the United States or beyond, you’ll get your industrial-grade SiC heater fast and reliable.

Reviews

There are no reviews yet.