Gotrays Chrome Corundum Castable Overview

Experience the power of Gotrays Chrome Corundum Castable, engineered specifically for unmatched erosion resistance in high temperature furnaces. Designed with a high alumina and chromium oxide blend, this advanced refractory castable offers exceptional protection against slag erosion, abrasion, and chemical attack in demanding industrial environments.

Our castable features a carefully balanced composition of chrome oxide corundum aggregate, premium binders, and additives to deliver superior structural integrity and long-lasting performance. Whether you need robust lining for steel mills, glass reactors, or coal slurry gasifiers, Gotrays Chrome Corundum Castable ensures extended service life with minimal maintenance.

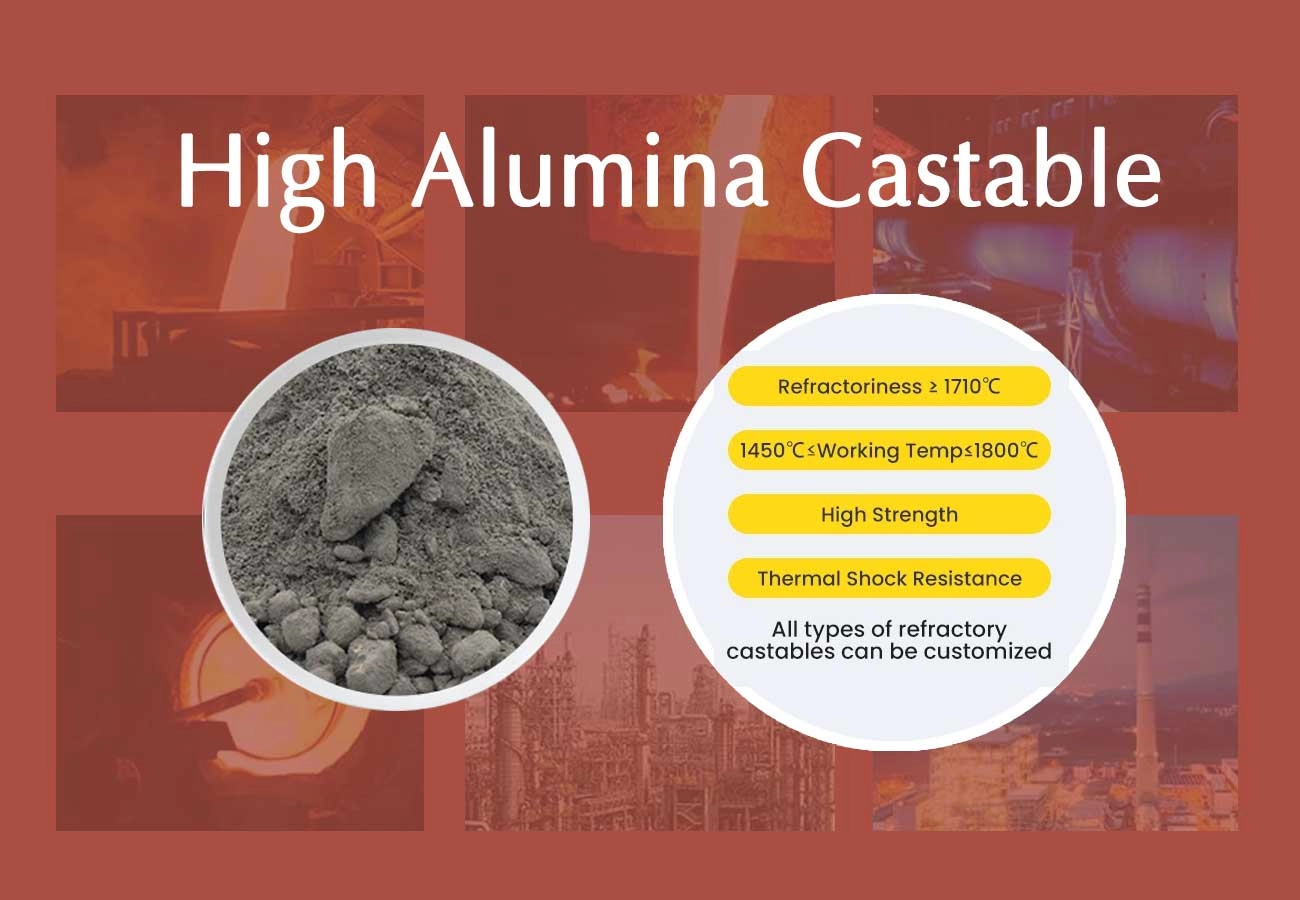

See it in action in the header image where its wear-resistant qualities shine in real industrial applications.

Ready to upgrade your furnace lining?

Request a free quote today and discover how Gotrays can protect your investment and boost operational uptime.

Technical Specifications

| Property | Value | Test Method |

|---|---|---|

| Aluminum Oxide (Al2O3) | 75% – 85% | XRF Analysis |

| Chromium Oxide (Cr2O3) | 12% – 18% | Wet Chemical |

| Bulk Density | 2.8 – 3.2 g/cm³ | ASTM C110 |

| Cold Crushing Strength | 45 – 60 MPa | ASTM C133 |

| Refractoriness | ≥ 1780°C (3240°F) | ASTM C704 |

| Linear Change | ±0.2% after 24 hrs at 1500°C | ASTM C531 |

| Service Temperature | Up to 1650°C (3000°F) | Operating Data |

Customizable Variants Available

- Low Cement Grades for reduced bonding agent, delivering improved high-temperature stability

- High Purity Grades for critical applications needing superior chemical resistance

- Adjustable chromium content tailored to your furnace operation demands

These options allow you to optimize your chrome corundum castable lining for maximum durability and performance in your specific industrial setup.

Key Features and Benefits

-

High Abrasion and Erosion Resistance

Gotrays Chrome Corundum Castable is built to stand up to heavy wear. It delivers extended lining life in your high-temp furnaces, cutting down on repairs and downtime.

-

Excellent Corrosion Resistance

Whether dealing with acidic or basic slags and gases, our chrome oxide corundum aggregate protects your equipment from harsh chemical attacks, keeping your furnace lining strong and reliable.

-

Superior High Temperature Strength

This castable maintains structural integrity even under extreme heat. You won’t see cracking, peeling, or structural failure, ensuring consistent performance over time.

-

Easy Casting and Fast Setting

With good flowability, the castable pours smoothly and sets quickly, making installation straightforward and efficient—perfect for busy plant schedules.

-

Eco-Friendly Low Chrome Options

We offer greener, low chrome variants to help you reduce environmental impact without sacrificing durability or performance.

Infographic: Compare Gotrays Chrome Corundum Castable to standard corundum castables for a quick look at why it outperforms in abrasion, erosion, corrosion, and high-temp toughness.

Composition and Manufacturing

Gotrays Chrome Corundum Castable is carefully formulated for top performance in tough furnace environments. It’s made from a precise mix of high-quality aggregates, fine powders, binders, and special additives to create a dense, durable lining.

Our unique manufacturing process uses high-temperature fusion to create a solid solution phase in the castable. This means the material achieves uniform density throughout with zero impurities, ensuring consistent strength and reliability. This fusion step also enhances the chrome oxide corundum aggregate’s natural erosion and corrosion resistance, giving you a lining that lasts longer under harsh conditions.

This careful blend and advanced process make Gotrays castable stand out as a high alumina chrome corundum mix that’s built for the demands of industries like steel, petrochemical, and power generation across the U.S.

Applications and Case Studies

Gotrays Chrome Corundum Castable is built to handle tough conditions across multiple industries. Here’s where it shines:

- Petrochemical: Perfect for reactors and high-temp chambers exposed to corrosive gases and slag.

- Metallurgy: Delivers long-lasting protection for furnaces, reducing downtime and maintenance costs.

- Waste Management: Withstands aggressive environments in waste incinerators and gasifiers.

- Glass: Improves furnace lining life, resisting erosion from molten glass and chemicals.

- Power Generation: Reliable in boilers and turbines, securing steady operation.

Real Results

In one US steel mill, Gotrays castable extended furnace lining life by 40%, cutting replacement frequency and labor costs. This boost led to a significant ROI, with less downtime and improved productivity — proving the value of our high chrome castable refractory.

If you want proven performance for your operation, Gotrays Chrome Corundum Castable offers durable, wear-resistant solutions tailored to your needs.

Installation and Usage Guidelines

Getting the best results from Gotrays Chrome Corundum Castable starts with proper installation. Here’s a simple step-by-step guide to help you through the process:

-

Surface Preparation

Clean the furnace lining thoroughly. Remove dust, loose particles, and oils to ensure good adhesion. Roughen smooth surfaces if needed to improve bonding.

-

Mixing Ratios

Follow the recommended water-to-castable ratio for your specific batch. Use clean water and mix uniformly until you get a smooth, flowable mix with no lumps.

-

Pouring and Vibration

Pour the mix carefully without trapping air pockets. Use vibration equipment to settle the castable evenly and eliminate voids. This step is key for strong, durable lining.

-

Curing

Allow the castable to set at ambient temperature for the initial phase. Then follow the gradual heating schedule in the manual to prevent cracking. Proper curing strengthens the lining and boosts erosion resistance.

Safety Notes

When handling chrome oxide (Cr2O3) in the castable, take these safety steps:

- Wear appropriate PPE including gloves, safety goggles, and dust masks

- Ensure good ventilation during mixing to avoid inhaling fine powders

- Follow all OSHA guidelines for refractory materials handling in your facility

For detailed steps, exact mixing ratios, and curing schedules, download our Installation Manual PDF. It’s packed with practical tips to make your job easier and your furnace lining last longer.

Ready to install? We’re here to support you every step of the way.

FAQs About Chrome Corundum Castable

How long is the shelf life of Gotrays Chrome Corundum Castable?

Our castable typically stays fresh and effective for up to 12 months when stored in a cool, dry place. Proper storage helps maintain its high-quality performance.

Can I prefabricate shapes with this castable?

Yes. The castable’s excellent flowability and quick setting make it ideal for prefabrication. You can mold complex shapes or panels before installation without losing strength or durability.

What is the usual lead time for orders?

Standard orders usually ship within 2 to 3 weeks, depending on quantity and customization. For large or custom high chrome castable batches, please contact us directly for precise timelines.

Is Gotrays Chrome Corundum Castable customizable?

Absolutely. We offer low cement and high-purity grades, along with adjustable chromium oxide (Cr2O3) levels to match your specific furnace lining needs.

What safety precautions should I take when handling the castable?

Use basic PPE like gloves, masks, and ensure good ventilation. Handling chromium oxide safely helps protect your team from dust exposure during mixing and installation.

Have more questions? Reach out anytime or request our detailed installation and safety manual for full guidance.

Pricing and Packaging

We offer flexible pricing options designed to fit your project size and specific needs. Our tiered pricing model rewards larger orders with volume discounts, helping you save as you scale up. Whether you need a standard chrome corundum castable or a custom blend with specific Cr2O3 levels, we can tailor the mix and pricing to match your requirements.

Pricing Highlights

- Competitive rates for low-volume and bulk orders

- Customizable Cr2O3 content for targeted erosion resistance

- Transparent quotes with no hidden fees

- Fast turnaround on pricing and delivery schedules

Get in touch today to request a tailored quote and see how our Gotrays Chrome Corundum Castable can deliver the best value for your high temperature furnace lining.

Related Products and Upsells

Explore our range of related refractory products designed to complement Gotrays Chrome Corundum Castable and boost your furnace’s performance. Our carousel features:

- High Chrome Castable Mixes for enhanced wear resistance

- Carbon Black Reactor Linings optimized for tough chemical environments

- Slag Erosion Resistant Castables to protect against harsh slags

For better durability, consider adding anti-spalling additives. These materials improve thermal shock resistance, reducing cracking and peeling during rapid temperature changes.

Upgrade your lining system with these products to get longer service life and lower maintenance costs.

Ready to enhance your setup? Ask us about custom blends or bundle deals for the best value.

Get in Touch with Gotrays

Ready to boost your furnace’s performance with Gotrays Chrome Corundum Castable? Reach out today for expert advice, tailored solutions, or a free quote. Our team is here to help you find the right abrasion-resistant furnace castable to meet your plant’s needs.

Contact Us

- Fill out our simple contact form for quick responses

- Call or email for personalized support

Trusted Quality You Can Rely On

Our Chrome Corundum Castable meets rigorous industry standards with certified testing to ensure top-notch performance. Gotrays products are trusted across U.S. industries for their unmatched erosion resistance and long service life.

Certifications Include

- ISO quality compliance

- ASTM test method validations

What Our Customers Say

“Since switching to Gotrays high chrome castable refractory, our furnace lining lasts longer and maintenance costs dropped significantly. The ROI was evident within months.” — Midwest Steel Plant Manager

“Gotrays Chrome Corundum Castable handled extreme slag conditions without cracking. We’re saving time and money with their fast, easy installation guidelines.” — Petrochemical Facility Supervisor

Reliable Shipping Across the U.S.

We ship nationwide with dependable logistics to ensure your refractory castables arrive on time and ready for use. Gotrays works with trusted carriers that understand the handling needs of high-quality refractory materials.

Shipping Benefits

- Fast delivery options

- Secure packaging to prevent damage

- Tracking provided for every order

Get your Chrome Corundum Castable lined up for success with Gotrays. Contact us today and experience the superior, wear-resistant refractory solution designed for high-temp furnaces in America.

Reviews

There are no reviews yet.