Gotrays Alumina Ceramic Bushings Engineered for Extreme Durability and Precision Insulation

Experience unmatched performance with Gotrays Alumina Ceramic Bushings designed to excel in the most demanding environments. Crafted from high-purity aluminum oxide (Al2O3) ranging from 95 to 99.8 percent purity, these bushings handle temperatures up to 1700°C without losing strength or stability.

Key Benefits

- Superior wear resistance for long-lasting operation

- Exceptional thermal stability

- Reliable electrical insulation in harsh conditions

Upgrade your system with bushings that outlast metal alternatives by five times in corrosive and high-friction applications.

Request a Custom Quote to find the perfect alumina ceramic bushing for your needs.

Product Overview

Gotrays Alumina Ceramic Bushings are built with high-purity aluminum oxide (Al2O3) for top-notch thermal stability, chemical resistance, and electrical insulation. These bushings are designed to perform flawlessly in mission-critical setups where reliability matters most.

By choosing Gotrays, you reduce downtime and slash maintenance costs since our alumina bushings last up to five times longer than metal alternatives, especially in tough, corrosive environments.

We offer standard tubular and flanged designs, plus custom shapes to fit your exact needs.

Key Features and Benefits of Alumina Ceramic Bushing

-

High Hardness (Mohs 9)

Resists wear and abrasion in tough, high-friction environments like pumps and industrial machinery.

-

Thermal Shock Resistance up to 300°C

Handles sudden temperature changes without cracking, perfect for furnace applications and aerospace parts.

-

Dielectric Strength over 20 kV/mm

Provides strong electrical insulation, making it reliable for high-voltage electrical and electronic uses.

-

Corrosion Resistance

Stands up to acids, bases, and harsh chemicals, ideal for chemical processing and food manufacturing.

Benefits Table

| Feature | Benefit | Industry Impact |

|---|---|---|

| 99.8% Purity Al2O3 | Enhanced mechanical strength | Longer service life in pumps and valves |

| Low Thermal Expansion | Minimizes cracking under heat | Safer operation in semiconductor manufacturing |

| Biologically Inert | FDA-compliant for food equipment | Meets hygiene standards in food processing |

Gotrays Alumina Ceramic Bushings deliver lasting performance by combining rugged wear resistance with electrical and chemical durability—helping reduce maintenance and keep operations running smoothly across industries.

Technical Specifications

Here’s a breakdown of Gotrays Alumina Ceramic Bushing specs designed to meet your exact needs:

| Specification | Details |

|---|---|

| Purity Levels | 95% to 99.8% Al2O3 (Aluminum Oxide) customizable based on application |

| Density | 3.8 to 3.98 g/cm³ depending on purity |

| Flexural Strength | Up to 350 MPa following ASTM C1161 |

| Maximum Use Temperature | Continuous up to 1700°C (3092°F) |

| Dielectric Constant | Approximately 9.8 at 1 MHz |

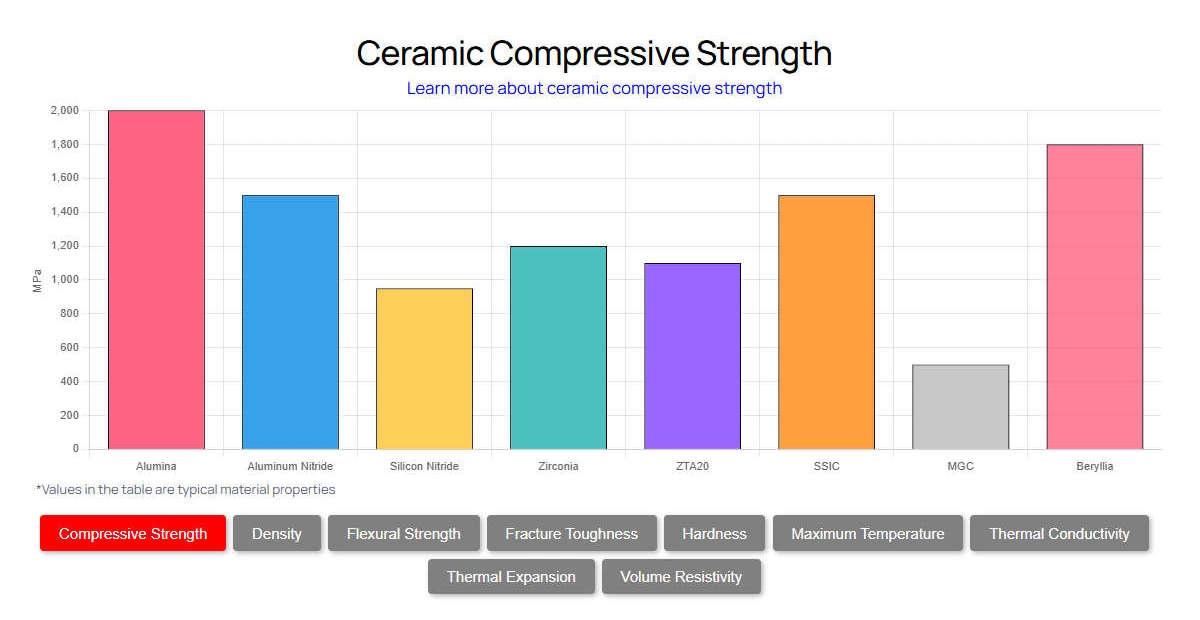

| Compressive Strength | Greater than 2500 MPa |

Our bushings hold tight tolerances with inner and outer diameters accurate to ±0.01 mm, and lengths up to 300 mm available.

Rest assured, all materials carry RoHS and ISO 9001 certifications, ensuring quality, safety, and compliance for your industrial or electrical applications.

Applications and Use Cases

Gotrays Alumina Ceramic Bushings work across several key industries thanks to their durability and reliability:

-

Electrical and Electronics

Perfect for cable terminations and insulators in high-voltage setups, where strong electrical isolation is a must.

-

Mechanical

Used as bearings and piston sleeves in pumps, these bushings minimize friction and extend equipment life.

-

High Temperature

Ideal for furnace tubes and thermocouples, especially in aerospace and metallurgy applications that demand heat resistance.

-

Chemical and Food Processing

Act as corrosion barriers in chemical reactors and hygienic mixers, standing up to harsh acids and bases while meeting FDA requirements.

Real Results

One of our clients in the semiconductor industry saw a 40% reduction in wear by using Gotrays Alumina Ceramic Bushings in their CVD chamber. This cutting-edge solution helped them cut downtime and save on maintenance.

Explore the full case results to see how these bushings can elevate your operation.

Customization and Manufacturing

We build every Gotrays Alumina Ceramic Bushing with precision using high-temperature sintering followed by advanced CNC grinding and polishing. This process ensures top-notch durability and exact fit for your application.

You can choose from several purity grades, shapes, and finishes:

- Cylindrical, flanged, or multigrooved designs

- Purity levels from 95% up to 99.8% Al2O3

- Smooth surface finishes down to Ra 0.1 micron

Our lead times are typically 4 to 6 weeks for prototypes, with faster turnaround available for larger orders. Ready to get started? Upload your CAD file now for an instant, custom quote tailored to your needs.

Quality Assurance and Compliance

At Gotrays, quality is non-negotiable. Every Alumina Ceramic Bushing goes through 100% visual inspection to catch any surface defects right away. We also perform batch sampling tests to verify thermal stability and electrical properties, ensuring every batch meets strict performance standards.

Our bushings carry key certifications like REACH and are UL-listed for insulators, so you can trust their safety and reliability in your applications.

Plus, our manufacturing process focuses on sustainability. Gotrays Alumina Ceramic Bushings are recyclable and made using low-energy production methods, reducing environmental impact while delivering top-notch quality.

Pricing and Purchasing

Our Gotrays Alumina Ceramic Bushings start at just $10 per unit, with volume discounts that make larger orders more affordable. Whether you need a small batch or bulk quantities, we’ve got flexible pricing to fit your budget.

Bulk Options

- Minimum order quantity (MOQ) of 50 units

- Competitive pricing for large volume purchases

- Reliable global shipping to your location in the U.S. and beyond

Ready to buy?

- Add to Cart for quick checkout on standard sizes

- Contact Sales for personalized bulk pricing and custom orders

Get the best value without compromising on quality or delivery times.

Related Products and Resources

Looking for more ceramic solutions? Check out our Alumina Ceramic Tubes, Zirconia Bushings, and Insulator Sets. Each product is designed to meet tough industrial demands while offering excellent durability and performance.

Need detailed info? Download our PDF datasheet and installation guide to get easy-to-follow specs and setup tips.

Frequently Asked Questions

-

How do I install Gotrays alumina ceramic bushings?

Installation is straightforward—ensure the surface is clean and free of debris, then carefully fit the bushing into place without forcing it. Follow the included guide for best results.

-

What is the difference between 95 percent and 99 percent purity alumina bushings?

Higher purity (99%) means better mechanical strength, improved wear resistance, and superior electrical insulation. Choose 95% for cost-efficiency in less demanding situations.

Get Started with Gotrays Alumina Ceramic Bushings

Join over 200 industrial clients who trust Gotrays for 5-star reliability and long-lasting performance. With more than 15 years in advanced ceramics, we deliver quality you can count on.

Have questions or need support? Reach out anytime by phone, email, our contact form, or live chat. We’re here to help you find the perfect alumina ceramic bushing for your needs.

Choose Gotrays—experience durability, precision, and service you can rely on. Request your custom quote today!

Introduction Addressing Core Pain Points

Tired of swapping out bushings too often because they wear out or fail in tough environments? Gotrays Alumina Ceramic Bushings are built to last. Made from high-purity aluminum oxide (Al2O3), these bushings handle extreme heat, chemical exposure, and electrical stress far better than traditional metal parts.

Why choose Al2O3 over metal? Because alumina ceramic resists corrosion, won’t crack under thermal shock, and provides top-notch electrical insulation. That means less downtime, fewer maintenance headaches, and parts that keep your equipment running smoothly longer. If you need a bushing that stands up to the harsh conditions of U.S. industrial settings, Gotrays has you covered.

In-Depth Product Breakdown

What Makes Gotrays Alumina Ceramic Bushings Superior

Gotrays Alumina Ceramic Bushings are built from high-purity aluminum oxide (Al2O3), ranging from 95% to 99.8%. This purity level is critical—it boosts mechanical strength, wear resistance, and provides excellent electrical insulation. The more pure the alumina, the better it performs under tough conditions like high heat and chemical exposure.

Design matters too. Our bushings come with options like flanged edges to simplify installation and prevent movement during use. We also offer custom shapes and sizes tailored for your specific needs, ensuring the perfect fit for any application.

Technical Specifications at a Glance

| Specification | Details |

|---|---|

| Purity Range | 95% – 99.8% Al2O3 |

| Maximum Temperature | Up to 1700°C |

| Dielectric Strength | Over 20 kV/mm |

| Hardness (Mohs) | 9 (Highly abrasion resistant) |

| Thermal Shock Limit | Δ up to 300°C |

| Density | 3.8 – 3.95 g/cm³ |

| Dimensions | Customizable ID, OD, lengths |

This clear breakdown means you get all the facts for accurate decision-making.

Proven Applications Across Industries

Gotrays Alumina Ceramic Bushings thrive in many sectors:

- Electrical: Cable terminations and high-voltage insulators

- Mechanical: Bearings and piston sleeves in pumps

- High-Temperature: Furnace tubes and aerospace sensors

- Chemical: Corrosion barriers and food-grade mixers

Our bushings have reduced wear by 40% in semiconductor chambers for U.S.-based manufacturers, proving they deliver in real-world conditions.

You can trust Gotrays alumina oxide bearing sleeves to stand up where others fall short, saving time and cutting maintenance costs.

Buyer’s Guide Selecting the Right Alumina Ceramic Bushing

Choosing the right Alumina Ceramic Bushing for your operation comes down to a few key factors. Here’s how to make the best pick for your needs:

What to Consider

- Load Capacity: Understand the mechanical stresses your bushing will handle. Gotrays Alumina Ceramic Bushings offer high compressive strength that outperforms metal alternatives, especially in heavy-duty setups.

- Operating Environment: Are you working in corrosive chemical conditions, high temperatures, or electrical isolation scenarios? Our bushings excel in all these environments thanks to their purity levels (95-99.8% Al2O3) and design.

- Electrical Requirements: For high voltage systems, look for dielectric strength—Gotrays bushings provide over 20 kV/mm for reliable insulation.

- Geometry & Size: Choose from standard tubular, flanged, or custom shapes. Precise tolerances (+/- 0.01 mm) ensure a perfect fit, even for tight specs.

Comparing Gotrays Alumina Bushings vs Steel Bushings

| Feature | Gotrays Alumina Ceramic Bushing | Steel Bushing |

|---|---|---|

| Wear Resistance | 5x better wear in corrosive conditions | Prone to rust and wear |

| Temperature Tolerance | Up to 1700°C | Limited, risk of deformation |

| Chemical Resistance | Excellent (acids, bases) | Vulnerable to corrosion |

| Electrical Insulation | High dielectric strength | Conductive, needs coatings |

| Maintenance | Low downtime, longer life | Frequent replacement |

Customization Services from Gotrays

We guide you through every step to get the perfect alumina solution:

- Send Your CAD File: Upload your design for a free, instant quote.

- Choose Purity Level: Between 95% and 99.8%, depending on required performance.

- Select Shape & Finish: Cylindrical, flanged, multi-grooved, or smooth finishes down to Ra 0.1 micron.

- Lead Time: Typically 4–6 weeks for prototypes; faster options for large volumes.

Ready to find your ideal alumina bushing? Let us help with expert advice and tailored manufacturing options.

Performance and Reliability Insights

Real-World Performance Data

Gotrays Alumina Ceramic Bushings consistently deliver outstanding results in tough conditions. Our clients report up to 40% less wear compared to traditional metal bushings, especially in semiconductor and chemical processing plants. Graphs from independent tests show superior abrasion resistance and stable performance at high temperatures, proving these bushings stand up to real-world demands.

Maintenance and Installation Best Practices

To get the most from your alumina oxide bearing sleeves:

- Clean bushings regularly to avoid buildup that can cause friction

- Use proper alignment tools during installation to prevent stress points

- Inspect periodically for cracks or surface wear

We also offer a quick video guide and checklist to simplify installation and maintenance, saving you time and reducing downtime.

Sustainability and Compliance Standards

Our alumina ceramic bushings are designed with the environment in mind. Made from recyclable materials, they require less energy to produce than metal alternatives. Gotrays products meet EPA regulations and comply with RoHS standards, helping you maintain eco-friendly operations without sacrificing performance.

Purchasing and Support Hub

Ordering Gotrays Alumina Ceramic Bushings is simple and straightforward. We offer clear pricing tiers designed to fit your budget, whether you need small runs or large volumes. Plus, we ship directly to local hubs across the U.S., so you get your products fast without hassle.

Have questions about alumina bushing tolerance specs or need advice on which part fits your setup? Our FAQ section covers the most common queries to help you make the right choice quickly.

Choosing Gotrays means partnering with a trusted name backed by real customer testimonials and 24/7 support. Our team is always ready to assist with technical help, order updates, or custom requests — keeping your operation running smoothly.

and Next Steps

Gotrays Alumina Ceramic Bushings deliver unmatched durability, wear resistance, and thermal stability for your toughest applications. With high-purity aluminum oxide, these bushings reduce downtime, cut maintenance costs, and outperform metal alternatives in harsh environments. Whether you need a standard size or a custom alumina oxide bearing sleeve, Gotrays has you covered.

Ready to elevate your operations? Get your custom Gotrays Alumina Ceramic Bushing quote today.

For more insights, check out our guide on Ceramic Insulators 101 and see how to choose the right ceramic solutions for your needs.

Reviews

There are no reviews yet.