Alumina Catalyst Carrier Engineered for Performance and Reliability

Looking for a catalyst support material that boosts efficiency and withstands harsh industrial environments? Our Alumina Catalyst Carrier delivers high surface area, exceptional thermal stability, and tailored porosity to maximize catalyst activity and lifespan. Whether you need gamma alumina support or porous alumina extrudates, our advanced alumina-based desulfurization carriers and inert alumina catalyst beds are designed to elevate your processes.

Why choose our Alumina Catalyst Carrier?

- Optimized catalyst dispersion for higher reaction rates

- Durable gamma alumina and boehmite-derived alumina spheres

- Customizable shapes and sizes including alumina tablets for hydrocracking

- Proven thermal stability to maintain structure in extreme conditions

- Consistent quality that meets US industry standards

Ready to boost your operations with a high-performance alumina catalyst carrier?

Contact us today for a free consultation and see how we can tailor solutions to your needs.

Key Features and Benefits

-

High Surface Area Alumina Carrier

Maximizes catalyst exposure for better reaction efficiency, helping you get more out of your process.

-

Thermally Stable Alumina Rings

Handles high temperatures without breaking down, ensuring longer service life in harsh conditions.

-

Porous Alumina Extrudates

Allows ideal flow and diffusion, improving reaction rates and minimizing pressure drops.

-

Inert Alumina Catalyst Bed

Prevents unwanted side reactions, keeping your process clean and consistent.

-

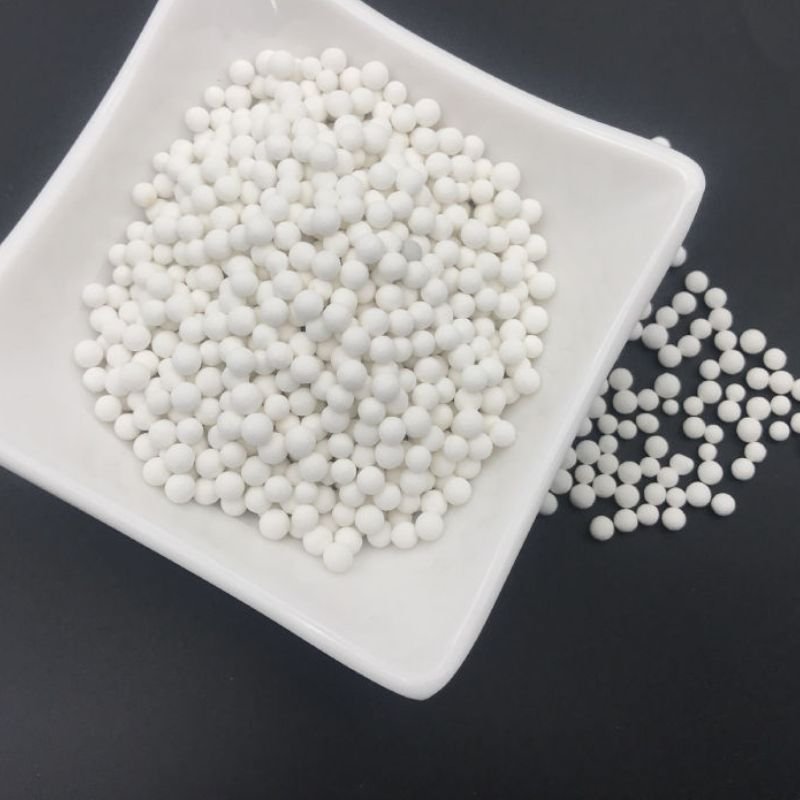

Boehmite Derived Alumina Spheres

Offers superior mechanical strength and durability, reducing wear and replacement costs.

-

Activated Alumina Balls

Enhance catalyst support with excellent adsorption properties, improving overall catalyst performance.

-

Alumina Tablets for Hydrocracking

Provide robust support specifically designed for hydrocracking units, increasing uptime and reliability.

Compare these features side-by-side with common options, and you’ll see our alumina catalyst carrier delivers a solid balance of durability, efficiency, and cost-effectiveness—perfect for meeting the demands of the US market.

Technical Specifications

Our alumina catalyst carrier is designed to meet the highest standards in the industry, ensuring reliable performance across various applications. Below is a quick look at its key properties and how we test them:

| Property | Typical Value | Test Method |

|---|---|---|

| Surface Area | 180 – 250 m²/g | BET Analysis |

| Bulk Density | 0.8 – 1.1 g/cm³ | Tap Density Test |

| Pore Volume | 0.4 – 0.7 cm³/g | Mercury Porosimetry |

| Pore Size Distribution | 10 – 150 nm | PSD Analysis |

| Thermal Stability | Up to 1300°F | Thermal Gravimetric Analysis |

| Mechanical Strength | > 35 N | Crush Strength Test |

Customization Options

We understand that each customer’s needs differ. That’s why we offer customization in:

- Shape and size (extrudates, spheres, rings)

- Surface area adjustments for specific catalyst reactions

- Pore size tuning to optimize flow and reactivity

Certifications and Compliance

Our alumina catalyst carriers come with full certification to meet US and international quality standards, including:

- ISO 9001 Quality Management

- RoHS Compliance for environmental safety

- Industry-specific certifications on request

For detailed specs or custom requests, reach out to us anytime. We’re here to help you find the best solution for your catalyst support material needs.

Applications and Use Cases

Our alumina catalyst carrier is a trusted choice across several industries in the United States. It serves as a reliable gamma alumina support in refining, petrochemical, and environmental sectors.

- Oil Refining: Used as alumina tablets for hydrocracking and desulfurization, improving fuel quality and meeting strict emissions standards.

- Chemical Manufacturing: Acts as an inert alumina catalyst bed for processes requiring high surface area alumina carriers to boost reaction efficiency.

- Water Treatment: Activated alumina balls help remove impurities like fluoride and arsenic, ensuring clean water supply.

- Automotive & Energy: Thermal stable alumina rings and porous alumina extrudates support catalysts in emission control and energy conversion applications.

Case Study Snippet

A U.S.-based refinery improved catalyst life and reduced downtime by switching to our Boehmite derived alumina spheres. The high thermal stability and porous structure helped maintain consistent activity under tough operating conditions.

These applications highlight how our alumina-based catalyst support material adapts to complex needs, backed by proven performance and reliability.

Manufacturing and Quality Assurance

At Gotrays, our alumina catalyst carrier is made using a carefully controlled process that ensures top quality every time. We use proprietary techniques to optimize the structure and surface area of our porous alumina extrudates, delivering consistent performance you can trust. From Boehmite derived alumina spheres to thermal stable alumina rings, each batch undergoes rigorous testing to meet strict quality standards.

Our quality assurance includes tests for surface area, porosity, strength, and thermal stability to ensure durability in demanding applications like hydrocracking and desulfurization. We continuously refine our process to boost catalyst support material effectiveness and extend lifespan.

For your convenience, detailed product certifications and test reports are available as downloadable resources. This transparency supports your compliance needs and helps you choose the right alumina catalyst carrier for your operations.

Customization and Sizing Options

We understand every project is different, so our alumina catalyst carrier comes in a variety of shapes and sizes to fit your exact needs. Whether you need gamma alumina supports in spheres, rings, tablets, or extrudates, we can tune the pore sizes and surface area for optimal performance. Our porous alumina extrudates and thermal stable alumina rings are customizable to improve catalyst effectiveness and durability in your system.

- Multiple shapes: spheres, rings, tablets, extrudates

- Sizes ranging from small pellets to larger carrier beds

- Pore size tuning for better catalyst activity and flow

- Surface area adjustment to enhance reaction efficiency

- Options for inert alumina catalyst beds and boehmite derived alumina spheres

Want to get a carrier tailored to your setup? Use our easy quote form to share your specs and get a custom solution that fits your application perfectly.

Pricing and Packaging

We offer tiered pricing on our alumina catalyst carriers to fit your project size and budget. Whether you need a small batch of activated alumina balls or bulk orders of porous alumina extrudates, our bulk discounts ensure you get the best value.

Our packaging is sturdy and designed to protect the high surface area alumina carriers during transit. We ship across the United States and internationally, making it easy to get thermal stable alumina rings or gamma alumina support wherever you need them.

Ready to get a custom quote? Contact us today for pricing details and shipping options tailored to your order size.

Why Choose Gotrays

At Gotrays, we understand the need for reliable alumina catalyst carriers that perform consistently in demanding U.S. industrial settings. Our brand is built on decades of experience delivering high surface area alumina carriers, like gamma alumina supports and porous alumina extrudates, trusted by customers nationwide.

What Sets Us Apart

- Proven Quality: We use advanced manufacturing techniques to produce thermally stable alumina rings and activated alumina balls, ensuring durability and peak catalyst support material performance.

- Customer Focus: We listen closely to your needs, offering tailored alumina tablets for hydrocracking and inert alumina catalyst beds that fit your specific process requirements.

- Innovation: Our proprietary pore tuning and boehmite derived alumina spheres provide superior desulfurization carrier options to keep your operations efficient and compliant.

Testimonials

“Switching to Gotrays alumina catalyst carriers improved our plant uptime by 15%. The quality and support are unmatched.” – Refinery Operations Manager, Texas

“Gotrays delivers exactly what we need. Their customization options and fast delivery make them our go-to supplier.” – Catalyst Procurement Lead, Louisiana

Competitor Comparison

| Feature | Gotrays | Competitor A | Competitor B |

|---|---|---|---|

| High Surface Area | Yes | Limited | Yes |

| Customization Options | Extensive | Basic | Moderate |

| Thermal Stability | Superior | Moderate | Low |

| Bulk Pricing & Shipping | Flexible with US-wide reach | Limited to regional hubs | Moderate |

| Customer Support | 24/7 Dedicated Team | Business hours only | Limited |

Choosing Gotrays means you’re backed by a trusted partner with the expertise and service you need to keep your catalyst systems running strong.

Related Products and Resources

Looking for more solutions? Check out our range of catalyst support materials designed to complement our alumina catalyst carrier. From activated alumina balls to porous alumina extrudates, we’ve got the right fit for your industrial needs.

Explore these related products:

- Gamma alumina support – great for high surface area applications

- Alumina tablets for hydrocracking – ideal for refining processes

- Thermal stable alumina rings – perfect for high-temperature operations

- Boehmite derived alumina spheres – known for reliable performance in catalyst beds

Need to deepen your knowledge? Our resource center offers guides, case studies, and technical papers on alumina-based desulfurization carriers and inert alumina catalyst bed setups. It’s all tailored for U.S. industries aiming to boost efficiency and durability.

Stay ahead with practical insights and the products that support your success.

Get your personalized quote today and experience the Gotrays difference.

Reviews

There are no reviews yet.