What is Alumina Castable Refractory A Complete Guide

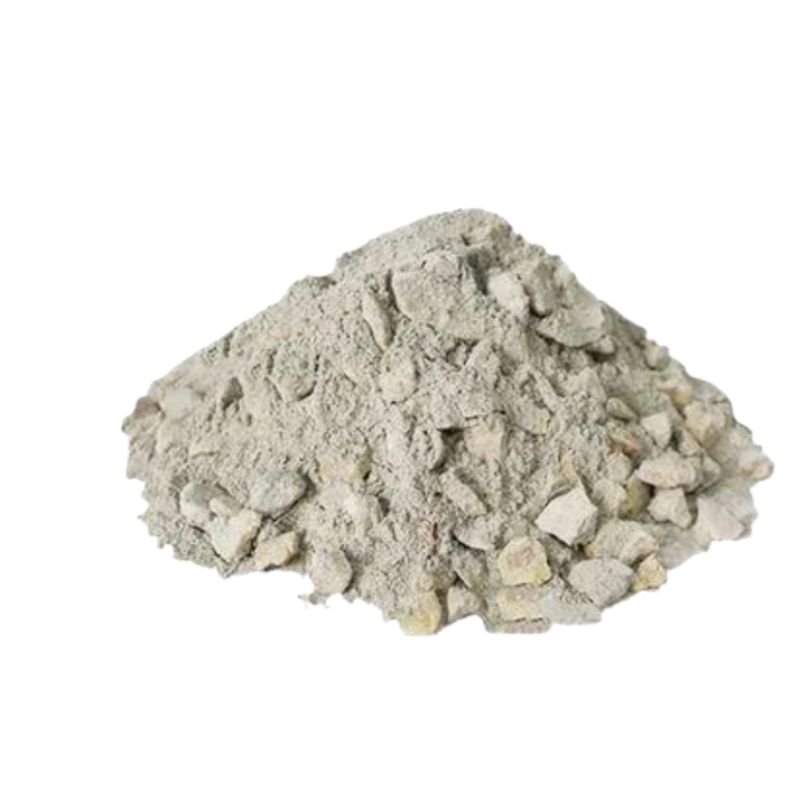

Alumina castable refractory is a high-performance, monolithic refractory material made from high-Al2O3 (aluminum oxide) aggregates combined with special binders like alumina hydraulic cement. This cementitious mix forms a dense, heat-resistant lining that can be cast, poured, or shaped on-site, making it ideal for high-temperature furnace linings and industrial applications requiring abrasion and thermal shock resistance.

Composition

- High alumina aggregates: Provide excellent thermal stability and mechanical strength

- Binders: Typically alumina hydraulic cement or low-cement formulations to enhance chemical stability

- Additives: May include modifiers to improve workability and durability

Types of Alumina Castables

| Type | Description | Pros | Cons |

|---|---|---|---|

| Dense Castable | High density with low porosity | Strong, abrasion resistant | Heavier, slower heat-up time |

| Low Cement Castable | Reduced cement for better stability | Better chemical resistance | Requires precise mixing |

| Insulating Castable | Lightweight with porous structure | Excellent thermal insulation | Lower mechanical strength |

How Alumina Castables Differ From Bricks and Plastic Refractories

- Monolithic Advantage: Unlike bricks or plastic refractories, alumina castables are applied as a single, continuous lining without joints, lowering failure points.

- Flexibility: Castables can be molded to complex shapes and repaired on site, while bricks require pre-molding and more labor.

- Thermal Performance: Castables provide better resistance to thermal shock and abrasion compared to plastic refractories, which often have higher binder content and lower alumina levels.

Alumina castable refractory is a versatile, durable option that outperforms traditional refractories in many industrial and commercial settings, delivering reliability and ease of installation.

Key Features and Technical Specifications of Gotrays Alumina Castable

Gotrays Alumina Castable stands out with its strong balance of thermal resistance, abrasion tolerance, and chemical stability, making it a reliable choice for demanding industrial uses.

Key Features

- High thermal resistance: Handles extreme temperatures without breaking down.

- Thermal shock resistant: Withstands rapid temperature changes to prevent cracking.

- Abrasion tolerant: Durable under mechanical wear, ideal for heavy-duty environments.

- Chemical stability: Resists acids and slags, ensuring long-lasting performance.

- Low cement content: Improves strength and reduces shrinkage for better durability.

Technical Specifications

| Specification | Value |

|---|---|

| Alumina (Al2O3) Content | 75% – 85% |

| Bulk Density | 2.45 – 2.60 g/cm³ |

| Maximum Service Temp | Up to 3200°F (1760°C) |

| Modulus of Rupture (MOR) | 8 – 12 MPa |

| Cold Crushing Strength (CCS) | 50 – 70 MPa |

Performance Data

Gotrays Alumina Castable features low thermal conductivity, which improves energy efficiency in furnace linings. Our tests show steady thermal conductivity even as temperatures approach 3000°F.

- Thermal conductivity decreases as temperature rises, helping retain heat better and reduce energy costs.

- Consistent mechanical strength across operating temperatures ensures reliability during long-term use.

With these technical qualities, Gotrays Alumina Castable offers a robust, energy-saving option for high-temperature applications in U.S. industries.

Ideal Applications for Gotrays Alumina Castable Refractory

Gotrays Alumina Castable Refractory is a go-to solution for many tough industrial and commercial needs across the U.S. Its durability and high thermal resistance make it perfect for heavy-duty environments.

Industrial Uses

- Steel Ladles: In Midwest steel plants, Gotrays castable helps line steel ladles that handle molten metal, resisting abrasion and thermal shock for longer life.

- Aluminum Smelters: It’s trusted in aluminum smelting operations where high Al2O3 content and chemical stability are crucial for withstanding corrosive slags.

- Cement Kilns: Cement manufacturers rely on this refractory in their rotary kilns for efficient heat retention and resistance to harsh chemical exposure.

Commercial and Consumer Applications

- Forges: Small-scale blacksmiths and hobbyists use Gotrays high alumina castable for forging setups to handle intense heat without cracking.

- Pizza Ovens: Its insulating version retains heat efficiently, ideal for commercial or backyard pizza ovens that need consistent, high temperatures.

- Incinerators: From municipal to industrial units, the refractory withstands high temps and abrasion, extending the life of incinerator linings.

Regional Focus Midwest Manufacturing

In the Midwest, where steel and aluminum production is a backbone of the economy, Gotrays alumina castable is favored for its balance of performance and cost. Local foundries and plants benefit from its reliability, helping reduce downtime and maintenance costs.

With real-world applications spanning heavy industry to smaller commercial setups, Gotrays Alumina Castable Refractory fits well with the varied needs of U.S. manufacturing and consumer users alike.

Benefits Why Gotrays Outperforms Standard Refractory Castables

When it comes to alumina castable refractory, Gotrays stands out from the crowd. Here’s why more U.S. manufacturers and fabricators trust our product over standard refractory castables:

Cost Savings

- Gotrays alumina castable lasts longer, cutting down how often you need replacements.

- Less downtime for repairs means more productivity and fewer unexpected expenses.

Efficiency

- Our low thermal loss formula reduces energy bills by up to 20%.

- Keeping heat where it belongs means your furnace or kiln runs more efficiently, saving fuel and electricity.

Sustainability

- Gotrays uses a low-cement, high-alumina composition that’s greener for operations.

- This helps reduce CO₂ emissions during production and extends service life, lowering overall environmental impact.

Comparison Gotrays Alumina Castable Versus Competitors

| Feature | Gotrays Alumina Castable | Mizzou Plus Castable | Standard Castable |

|---|---|---|---|

| Al2O3 Content (%) | 75-85 | 70-80 | 60-70 |

| Thermal Loss Reduction | Up to 20% | Around 15% | 10% or less |

| Service Life (hours) | 20,000+ | 15,000+ | 10,000+ |

| Sustainability (Low Cement) | Yes | Partial | No |

| Abrasion Resistance | High | Medium | Low |

| Price Competitiveness | Moderate | Similar | Lower but less durable |

Gotrays brings a balance of performance, efficiency, and eco-friendliness that standard refractory castables struggle to match—making it the smart choice for Midwest steel plants, aluminum smelters in the Southeast, or cement kilns nationwide.

Step-by-Step Installation Guide for Alumina Castable Refractory

Installing Gotrays Alumina Castable Refractory is straightforward when you follow the right steps. Here’s a quick guide to get you started with mixing, casting, curing, and firing.

Mixing and Preparation

- Mix Ratios: Use the recommended water-to-castable ratio on the bag. Usually, it’s about 5-6% water by weight but always check the product label.

- Tools Needed: Mixing drill with paddle, clean water, measuring bucket, and protective gear (gloves, mask).

- Mixing: Add water first, then slowly add the alumina castable while stirring steadily. Mix for 3-5 minutes until you get a smooth, lump-free slurry.

Casting and Curing

- Casting: Pour or pump the castable into molds or directly onto the surface. Use vibration tools or tap the formwork gently to remove air pockets.

- Vibration Tips: If you can’t use a vibrator, tap the sides or use a rubber mallet to settle the castable evenly.

- Curing: Keep the castable moist by covering it with plastic sheets or damp burlap for at least 48 hours to prevent cracking.

Firing Schedule

- Slow Heating: Heat up gradually, starting at around 200°F per hour. This helps drive off moisture safely.

- Target Temperature: Reach your operational temperature (typically up to 3000°F depending on your castable type) steadily. Avoid rapid spikes to reduce thermal shock.

- Ramp-up Cycle: Follow the specific firing guidelines from Gotrays for the best performance.

Troubleshooting Common Issues

| Issue | Cause | Fix |

|---|---|---|

| Overwatering | Adding too much water | Add dry castable to balance moisture |

| Cracking during cure | Inadequate moist curing or heat | Cover longer; slow down curing temperature |

| Air pockets in cast | Poor vibration or mixing | Use vibration tools or tap formwork |

| Loss of strength | Incorrect mix ratio | Follow specified water-to-castable ratio |

Video Guide

For a clearer step-by-step, check out our installation video embedded below. It covers mixing, casting, curing, and firing to help you avoid common mistakes and get the best results on your project.

This straightforward installation process ensures your Gotrays Alumina Castable Refractory delivers strong, long-lasting performance tailored for your industry needs.

Gotrays Quality Assurance and Certifications

At Gotrays, quality is non-negotiable. Our alumina castable refractory goes through strict testing protocols to ensure top performance. We meet and often exceed ASTM and ISO standards for durability, thermal resistance, and chemical stability. This means you get a product built to last in demanding industrial environments.

A recent case study from a Texas foundry showed a 40% reduction in downtime after switching to Gotrays alumina castable. This real-world result proves the reliability and efficiency of our refractory in heavy-use situations.

Our customers agree, rating Gotrays alumina castable a solid 4.8 out of 5 stars for performance, ease of installation, and service life. This trusted reputation reflects our commitment to consistent quality and support tailored to U.S. industry needs.

Pricing Sizing and Ordering Gotrays Alumina Castable Refractory

When it comes to buying Gotrays Alumina Castable Refractory, you have flexible options to fit your project size:

-

Packaging Options

25 kg bags for smaller jobs or repairs

Bulk orders by the ton for big industrial needs

Special bulk discounts available for large volume purchasesSizing Guidance

Choose based on your lining thickness and volume needed

We offer support to help calculate the right amount for youLocal Pricing Estimator

Enter your ZIP code on our website to get region-specific pricing

This helps account for shipping costs and local material demandCommon Pricing FAQs

What’s the price for bulk alumina castable near me?

Prices vary by location and order size, but bulk orders start around competitive market rates. Use our estimator for exact numbers in your area.

-

What’s the lead time for a 5-ton order?

Typical lead times range between 5 to 10 business days depending on demand and location. We always aim for fast, reliable delivery to keep your project on track.

If you’re ready to buy or want a custom quote, contact Gotrays for a quick estimate tailored to your project size and location.

Frequently Asked Questions About Alumina Castable Refractory

What’s the maximum temperature Alumina Castable can handle?

Gotrays Alumina Castable Refractory withstands continuous service temperatures up to 3200°F (1760°C), making it ideal for most high-temperature furnace linings and industrial uses.

Is this castable safe for DIY forges and small backyard furnaces?

Yes, it’s safe and effective for DIY projects like hobby forges or pizza ovens, as long as you follow installation and firing procedures carefully.

How long does it take to cure before use?

Typically, initial curing takes about 24–48 hours. Full strength develops over 7 days with proper moisture and firing regimes.

Can I apply Alumina Castable directly on existing brickwork?

Yes, monolithic Alumina Castable bonds well to sound, clean brick surfaces, providing a seamless lining without gaps.

What are signs of poor installation to watch for?

Look out for cracks during curing, excessive dusting, or weak spots caused by overwatering or improper mixing.

How do I store unused castable?

Keep bags dry and sealed. Store in a cool, dry place for up to 6 months to maintain performance.

Is low cement content important?

Yes, low cement castable refractories like Gotrays reduce shrinkage and improve thermal shock resistance.

What’s the shelf life of Gotrays Alumina Castable?

Stored unopened and dry, shelf life is around 6 to 12 months depending on storage conditions.

Can it handle thermal shock well?

Absolutely. It’s designed for thermal shock resistance, making it suitable for fluctuating heat environments.

Where can I find local pricing and order samples?

Use our online pricing estimator by entering your ZIP code or contact your regional distributor to get samples and quotes fast.

Related Gotrays Products and Resources

Looking to complement your alumina castable refractory? Gotrays offers a range of high-quality products designed to work perfectly with our castables:

- High-Alumina Mortars: Ideal for bonding castable linings, repairs, or applications needing strong adhesion and heat resistance.

- Precast Shapes: Ready-made refractory shapes that save installation time and ensure consistent performance in tough environments.

We also provide technical downloads like our detailed Product Data Sheets (PDS) and easy-to-follow installation guides so you have everything you need to get the job done right.

Want to try before you buy? Get a Free Sample of Gotrays Alumina Castable shipped locally to your door. Experience the quality firsthand and see why our products stand out in the United States market.

Reviews

There are no reviews yet.