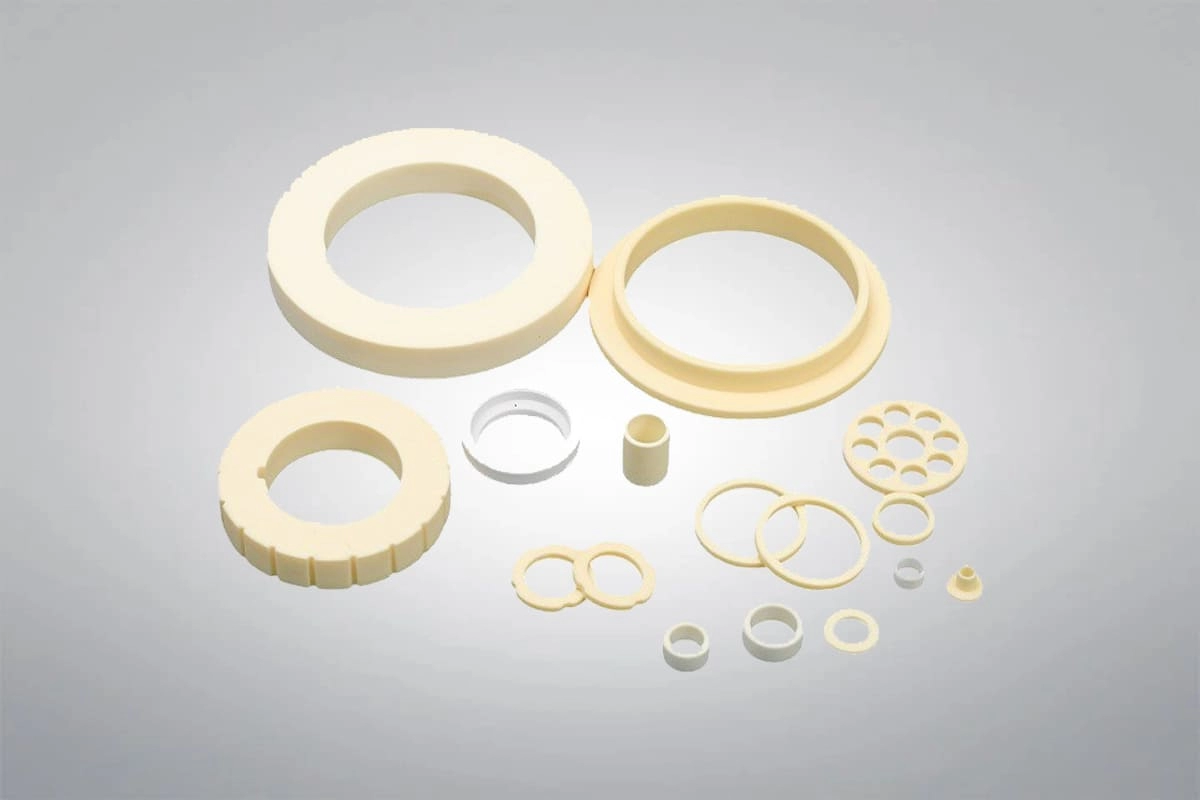

If you’re searching for alumina ceramic rings that combine unmatched wear resistance, precision tolerance, and electrical insulation, you’ve come to the right place. In 2025, these rings remain the go-to solution across industries—from aerospace and semiconductor manufacturing to medical devices and mechanical seals. But not all alumina ceramics are created equal. Understanding the differences in purity levels, mechanical properties, and manufacturing precision can save you time and cost while ensuring optimal performance.

This guide cuts through the noise with detailed insights on 95% to 99.9% Al₂O₃ grades, tight dimensional controls down to ±0.001 mm, buyer-centric pricing transparency, and real-world applications. Whether you’re a procurement manager vetting suppliers or an engineer specifying parts, you’ll find everything needed to make a confident, data-backed decision. Plus, discover why manufacturers like Gotrays have earned trust over 15 years by delivering high-quality, customizable alumina ceramic rings on time and under budget.

Let’s get straight to the facts and figures that matter for your next project.

Alumina Purity Levels Explained: Which Grade Should You Choose?

Alumina ceramic rings come in different purity levels, mainly expressed as the percentage of Al₂O₃ content. Common grades include 95%, 96%, 99%, 99.5%, 99.7%, and 99.9%. Purity affects the ring’s hardness, thermal conductivity, electrical insulation, and cost. Choosing the right grade depends on your application’s performance requirements and budget.

Key Differences: Purity vs Properties

| Purity (%) | Hardness (Mohs) | Thermal Conductivity (W/m·K) | Dielectric Strength (kV/mm) | Price Tier* |

|---|---|---|---|---|

| 95% | 14.0 | 15 – 18 | 10 – 12 | Low |

| 96% | 14.5 | 16 – 19 | 12 – 14 | Low-Medium |

| 99% | 15.0 | 20 – 22 | 14 – 16 | Medium |

| 99.5% | 15.5 | 22 – 24 | 16 – 18 | Medium-High |

| 99.7% | 16.0 | 23 – 25 | 17 – 19 | High |

| 99.9% | 16.0+ | 24 – 26 | 18 – 20 | Highest |

*Price tier reflects typical market pricing relative to purity; actual costs vary by volume and supplier.

What Does This Mean for You?

- 95% – 96% alumina: Suitable for less demanding wear-resistant applications and general insulation where cost is critical.

- 99% – 99.5% alumina: Most popular choice for mechanical seal rings, offering a good balance of hardness, thermal resistance, and dielectric strength.

- 99.7% – 99.9% alumina: Used for high-performance parts needing exceptional wear resistance, thermal conductivity, and insulation, such as aerospace and semiconductor components.

In short, the higher the alumina purity, the better the mechanical and electrical properties—but at a higher price. Selecting the right grade means balancing performance with cost-efficiency, tailored to your specific needs.

Key Physical and Mechanical Properties of Alumina Ceramic Rings

Alumina ceramic rings are prized for their outstanding physical and mechanical properties, making them reliable in demanding applications.

Hardness:

- On the Mohs scale, alumina ranks around 9, just below diamond and silicon carbide, meaning it’s very scratch-resistant.

- Vickers hardness typically ranges from 1300 to 2000 HV depending on purity and processing.

Compressive & Flexural Strength:

- Compressive strength can reach up to 3,000 MPa, allowing alumina rings to withstand heavy loads without deformation.

- Flexural strength typically lies between 300 to 450 MPa, ensuring good resistance to bending stresses.

Thermal Shock Resistance & Max Service Temperature:

- Alumina rings have excellent thermal shock resistance compared to other ceramics, tolerating rapid temperature changes without cracking.

- They can operate continuously at temperatures up to 1700°C in some grades, making them ideal for high-temperature environments.

Electrical Insulation & Dielectric Properties:

- Alumina is an excellent electrical insulator with dielectric strength ranging from 10 to 15 kV/mm.

- Its low dielectric loss makes it suitable for critical insulation rings and high-voltage applications, often referred to as dielectric ceramic rings.

Wear and Corrosion Resistance:

- Alumina offers superior wear resistance, often outperforming metals and plastics. Real-world wear tests show that alumina rings can reduce friction by 30-50% compared to steel under similar conditions.

- Corrosion resistance is excellent against acids, alkalis, and organic solvents, maintaining structural integrity where many metals fail.

These balanced properties define why alumina ceramic rings are the preferred choice in applications requiring wear resistance, electrical insulation, and strength under harsh conditions. For comparison on wear resistance with other ceramic options, consider checking our details on nitride-bonded SiC pump parts, which complement alumina’s performance in abrasive environments.

Manufacturing Processes: How High-Quality Alumina Rings Are Made

Producing top-grade alumina ceramic rings starts with choosing the right forming method. Common techniques include dry pressing, cold isostatic pressing (CIP), isostatic pressing, and injection molding. Each has its strengths: dry pressing is cost-effective for simpler shapes, while CIP and isostatic pressing deliver uniform density—key for high-performance alumina rings. Injection molding suits complex designs and volume production.

After shaping, the rings undergo sintering or hot isostatic pressing (HIP). Sintering fuses the ceramic particles at high temperature to build strength, while HIP applies heat and pressure simultaneously, producing parts with even higher density and fewer microscopic defects. This means better mechanical properties and longer-lasting ceramic rings.

At Gotrays, we also specialize in precision finishing. Our advanced grinding and lapping process can achieve a surface roughness as low as Ra 0.05 μm. This ultra-smooth finish boosts performance in applications requiring tight sealing or minimal wear, such as mechanical seal faces or insulating rings.

For reliable custom alumina ceramic rings with exacting tolerances, our integrated approach from pressing to precision grinding ensures consistent quality. Check out our range of high purity alumina ceramic rings to see how these manufacturing methods deliver the best value and performance.

Standard Dimensions and Tightest Tolerances We Can Achieve

Alumina ceramic rings come in a wide range of standard sizes to meet diverse industrial needs. Typical outer diameters (OD) range from 10 mm up to 150 mm, with inner diameters (ID) starting around 3 mm and heights varying between 2 mm and 50 mm. These sizes cover most common applications, from small precision ceramic rings used in electronics to larger wear-resistant ceramic rings for mechanical seals.

At Gotrays, we specialize in high-precision manufacturing, capable of achieving some of the tightest tolerances in the industry:

| Dimension | Tolerance |

|---|---|

| Outer Diameter (OD) | ±0.002 mm |

| Inner Diameter (ID) | ±0.002 mm |

| Perpendicularity | 0.01 mm |

| Parallelism | 0.005 mm |

Such accuracy ensures optimal performance in demanding applications like high-speed rotary equipment and tight mechanical seal faces, where even minor deviations impact reliability.

We also offer custom size capabilities for non-standard requirements. Whether you need a specific OD/ID/height combo or complex shapes, our in-house CNC grinding and lapping processes can deliver precision ceramic rings tailored to your exact specs.

For projects needing consistent surface finish and tight control, achieving Ra 0.05 μm surface roughness is possible, making these rings ideal as ceramic seal rings or alumina insulation rings in critical environments.

For related components, consider pairing alumina rings with other high-performance ceramics like silicon carbide impellers for enhanced durability in pump systems.

Major Applications & Industry Case Studies

Alumina ceramic rings are widely trusted across industries due to their outstanding wear resistance, electrical insulation, and high-temperature stability. Here are some key applications:

- Mechanical seals and pump components: Alumina’s hardness and corrosion resistance make it ideal for durable ceramic seal rings in harsh environments, ensuring leak-free operation and long service life.

- Semiconductor & LCD equipment: Precision ceramic rings serve as critical insulators and guides in ultra-clean manufacturing, where contamination and thermal stability are major concerns.

- High-voltage insulators and spark plug insulators: Thanks to excellent dielectric strength, alumina ceramic rings reliably isolate electrical components under extreme voltage stress.

- Textile machinery yarn guides: Alumina’s smooth, wear-resistant surfaces provide low friction and extend service intervals in high-speed textile operations.

- Medical implants and dental rings: Biocompatible and wear-resistant, alumina ceramics fit perfectly in demanding medical device applications.

- Aerospace and defense: High-temperature resistance combined with low weight makes alumina ceramic rings valuable in aerospace seals and safeguarding critical defense equipment.

Gotrays Project Highlights (Anonymized)

- Mechanical Seal Upgrade for a Chemical Plant: Replacing metal seals with 99.5% alumina ceramic rings reduced downtime by 30% due to enhanced corrosion and wear resistance.

- Semiconductor Chip Fabrication: Custom high-purity alumina ceramic guide rings improved process stability in LCD manufacturing, enabling tighter tolerances and longer equipment life.

- High-Voltage Switchgear Insulation: Gotrays supplied alumina ceramic insulator rings that passed stringent dielectric testing, helping a major utility company increase reliability.

- Textile Yarn Guide Retrofit: A leading textile machinery maker switched to our alumina ceramic rings to reduce wear-related failures, extending machine run time by 25%.

For more on precision manufacturing of alumina components, explore our alumina ceramic sleeve options designed for high-performance applications.

Alumina Ceramic Ring vs Competitors: Zirconia, Silicon Carbide, Silicon Nitride

When selecting a ceramic ring for your application, it\’s key to know how alumina stacks up against other popular technical ceramics like zirconia, silicon carbide (SiC), and silicon nitride (Si₃N₄). Here\’s a quick side-by-side look at performance and cost to help you pick the right material.

| Property | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Carbide (SiC) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|---|

| Purity Levels | 95%–99.9% | ~99% | >99% | >99% |

| Hardness (Mohs) | 9 | 8.5 | 9–9.5 | 8.5–9 |

| Fracture Toughness (MPa·m^0.5) | 3–4 | 10–12 | 4–5 | 7–10 |

| Thermal Conductivity (W/m·K) | 20–30 | 2–3 | 120–150 | 25–30 |

| Max Service Temperature (°C) | 1600 | 1200 | 1600+ | 1400 |

| Electrical Insulation | Excellent | Good | Poor (semiconductor) | Excellent |

| Wear Resistance | Good | Very good | Excellent | Very good |

| Price Tier | Low to Moderate | Moderate | High | High |

When to Choose Alumina Ceramic Rings

- Cost-sensitive projects: Alumina is generally more affordable than zirconia, SiC, or Si₃N₄, especially in high volumes.

- High electrical insulation: Alumina’s excellent dielectric properties make it a top choice for insulation rings and electrical components.

- Good wear resistance with adequate toughness: While its fracture toughness is lower than zirconia, alumina performs well in wear-heavy environments when hardness and corrosion resistance are priorities.

- High-temperature applications: Alumina can withstand service temperatures up to 1600°C, suitable for most industrial uses.

- Precision ceramic rings: When tight tolerance and surface finish matter, alumina’s proven manufacturing techniques provide reliable results.

In contrast, consider zirconia when you need higher toughness and fracture resistance, silicon carbide for extreme wear resistance and thermal conductivity, and silicon nitride if you require a balance between toughness and thermal shock resistance.

For customized alumina components with tight tolerances and excellent wear resistance, check options like our precision alumina hollow ball thermal insulation material, which demonstrate Gotrays’ capability in advanced ceramic parts manufacturing.

Price Guide 2025: How Much Do Alumina Ceramic Rings Really Cost?

When budgeting for alumina ceramic rings in 2025, it’s essential to understand how purity and order volume influence pricing. Here’s a straightforward breakdown to help you plan:

Price Ranges by Alumina Purity and Volume

| Purity Level (% Al₂O₃) | Small Batch (10–100 pcs) | Medium Batch (100–1,000 pcs) | Large Batch (1,000+ pcs) | Price Tier |

|---|---|---|---|---|

| 95% | $2.50 – $4.00 per ring | $2.00 – $3.50 per ring | $1.80 – $3.00 per ring | Entry-level |

| 96% | $3.00 – $4.50 per ring | $2.50 – $4.00 per ring | $2.20 – $3.50 per ring | Budget-friendly |

| 99% | $4.50 – $6.50 per ring | $4.00 – $6.00 per ring | $3.50 – $5.50 per ring | Mid-range |

| 99.5% | $5.50 – $7.50 per ring | $5.00 – $7.00 per ring | $4.50 – $6.50 per ring | High purity |

| 99.7% | $6.00 – $8.50 per ring | $5.50 – $8.00 per ring | $5.00 – $7.50 per ring | Premium quality |

| 99.9% | $7.00 – $10.00 per ring | $6.50 – $9.00 per ring | $6.00 – $8.50 per ring | Ultra-high purity |

Prices are indicative and can vary based on dimensions, complexity, and specific requirements.

Key Factors Influencing Final Pricing

- Purity Level: Higher purity alumina offers improved mechanical and electrical properties but costs more due to raw material quality and processing.

- Quantity: Larger orders reduce cost per unit through economies of scale.

- Dimensions & Tolerances: Tight tolerances and small features require more precise manufacturing, raising costs.

- Surface Finish: Achieving ultra-smooth finishes (Ra 0.05 μm or better) adds machining time and expenses.

- Testing & Certification: Full material certificates, custom tests, or inspection reports add to overall cost.

MOQ and Lead Time – The Real Deal

- Minimum Order Quantity (MOQ): Most manufacturers, including Gotrays, offer reasonable MOQs starting as low as 10 pieces for standard sizes. Custom orders may require higher minimums.

- Lead Time: Depending on purity and complexity, typical lead times range from 2 to 6 weeks. Expedited orders are often available but may come with premium pricing.

If you want a reliable partner for competitive high purity alumina rings with transparent pricing and realistic delivery, working with direct manufacturers like Gotrays can save you time and money over distributors.

For specialized projects requiring consistent quality and fast turnaround, we recommend checking our full range of precision ceramic rings to get accurate pricing and lead time estimates.

How to Choose the Right Alumina Ceramic Ring Supplier

Picking the right supplier can make or break your project when sourcing alumina ceramic rings. Here are 10 critical questions to ask any manufacturer or distributor before committing:

| Question | Why It Matters |

|---|---|

| 1. What purity grades of alumina do you offer? | Ensures you get the specific high purity alumina ring you need. |

| 2. Can you provide material certificates and test reports? | Guarantees quality and traceability. |

| 3. What are your dimensional tolerances? | Critical for precision fits and function. |

| 4. Do you handle in-house CNC grinding and lapping? | Means better control of surface finish (Ra 0.05 μm achievable). |

| 5. What is your MOQ and lead time? | Impacts project timelines and costs. |

| 6. Do you offer custom alumina ring sizes? | Flexibility for unique applications. |

| 7. What quality standards do you follow? | ISO certifications (like ISO 9001) show reliability. |

| 8. How do you handle customer support and after-sales service? | Crucial if you need technical help or reorders. |

| 9. Can you share references or case studies? | Validates proven industry experience. |

| 10. What are your pricing terms, and do you offer volume discounts? | Helps in budgeting and cost-saving decisions. |

Red Flags vs Green Flags in Choosing Suppliers

| Warning Signs (Red Flags) | Positive Signs (Green Flags) |

|---|---|

| Vague answers on purity or specs | Clear, detailed material certificates |

| No in-house processing capability | Own CNC grinding, lapping, and finishing |

| Long, unexplained lead times | Fast, transparent lead times (e.g., 72-hour quotation) |

| MOQ too high for small orders | Flexible MOQ and prototyping options |

| Poor or no customer reviews | Verified testimonials and industry case studies |

| No ISO or quality certifications | ISO 9001 and ISO 13485 certified |

Why Direct Chinese Manufacturers Like Gotrays Often Win on Price and Quality

- Lower Overheads: Gotrays runs its own factories, cutting out expensive middlemen.

- Full Process Control: From pressing to sintering and precision grinding, all done in-house ensures top quality and consistency.

- Competitive Pricing: Direct sales and efficient manufacturing lead to honest pricing with no markup layers.

- Customized Solutions: Rapid prototyping and flexible custom sizes are standard, not extras.

- Trusted Certifications: Gotrays holds ISO 9001 and ISO 13485, with full material certificates and test reports supplied.

- Fast Service: Free prototype samples plus a 72-hour quick quotation process make sourcing simple and reliable.

Choosing the right Al₂O₃ ceramic ring manufacturer isn’t just about price — it’s about finding a partner who understands your quality needs and can deliver on time without surprises. For example, Gotrays’ expertise compares favorably against distributors who rely on third-party manufacturers and can’t guarantee the same level of precision or service quality.

For more technical ceramics options like wear-resistant SiC tiles or ceramic spacers, seeing a manufacturer with broad capabilities — such as Gotrays — helps ensure end-to-end support. Check out related products like our nitride bonded SiC tile or quartz ceramic spacer for complementary applications.

Gotrays Advantage – Why Leading Companies Trust Us

At Gotrays, quality and reliability come first. We hold ISO 9001 and ISO 13485 certifications, ensuring our alumina ceramic rings meet the highest standards for both industrial and medical applications. Every batch is backed by full material certificates and detailed test reports, giving you peace of mind about product consistency and performance.

Our advanced in-house capabilities include precision CNC grinding, lapping, and laser engraving, allowing tight tolerances and fine surface finishes (Ra as low as 0.05 μm) on custom alumina rings. This level of control means we deliver exactly what your project demands—no guesswork.

We also offer a free prototype policy with fast, 72-hour quotations, so you can quickly evaluate our alumina ceramic rings for your specific use case. This customer-focused approach has made Gotrays the go-to manufacturer for leading companies worldwide.

For more about our material quality and manufacturing precision, check out our alumina ceramic sheet offerings, which share the same rigorous standards and craftsmanship.

FAQ – 15 Most Asked Questions About Alumina Ceramic Rings

Here are the top questions we get about alumina ceramic rings, answered clearly and quickly:

-

What purity level of alumina ceramic ring should I choose?

It depends on your application. Higher purity (99.5%–99.9%) offers better hardness, wear resistance, and electrical insulation but costs more. For general use, 95%-96% is often enough.

-

How hard are alumina ceramic rings?

Alumina rings typically rate 9 on the Mohs scale and 1300-1700 HV on the Vickers scale, making them very wear-resistant.

-

Can alumina rings handle high temperatures?

Yes, they can withstand up to 1700°C in continuous use and have excellent thermal shock resistance.

-

Are alumina ceramic rings good electrical insulators?

Absolutely, they have excellent dielectric strength and low conductivity, ideal for insulation applications.

-

What manufacturing methods are used?

Common processes include dry pressing, cold isostatic pressing (CIP), and injection molding, followed by sintering and precision grinding.

-

How precise can the dimensions get?

Standard tolerances can be as tight as ±0.002 mm for OD/ID, with parallelism and perpendicularity controlled within 0.005-0.01 mm.

-

Can you make custom-sized alumina rings?

Yes, custom sizes are available to fit nearly any specification you need.

-

What industries use alumina ceramic rings?

They’re widely used in mechanical seals, semiconductor equipment, high-voltage insulators, textile machinery, medical implants, and aerospace.

-

How do alumina rings compare to zirconia or silicon carbide?

Alumina is more affordable with solid wear and insulation properties, while zirconia offers higher toughness and silicon carbide higher thermal conductivity.

-

Is Gotrays compliant with quality standards?

Yes, we hold ISO 9001 and ISO 13485 certifications, including material traceability and full test reports.

-

How long does delivery take?

Typical lead time is 2-4 weeks depending on quantity and specifications, but prototypes can be quick, often within 72 hours.

-

What factors influence alumina ring prices?

Purity level, size, quantity, and machining precision all affect cost.

-

Are the rings wear-resistant in real conditions?

Yes, tests show alumina rings maintain integrity even under abrasive and corrosive environments.

-

Can I get samples before ordering?

Yes, Gotrays offers free prototype services to help you evaluate before full production.

-

Where can I find matching alumina components?

We also provide related products like ceramic fiber yarn and precision mullite bricks, perfect for complementary applications.

Have more questions? Reach out directly to discuss your specific needs and get expert advice.