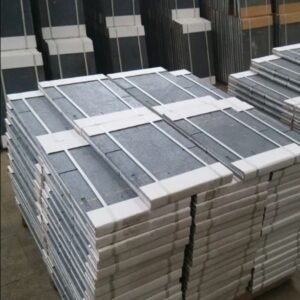

Discover the Power of Nitride-Bonded SiC Tiles

Nitride-bonded silicon carbide (NBSiC) tiles are advanced refractory materials made by bonding silicon carbide (SiC) particles with silicon nitride (Si3N4) through a specialized high-temperature furnace process. This method creates strong, dense tiles designed to withstand extreme thermal and mechanical stress.

The NBSiC manufacturing process involves heating silicon carbide and nitrogen gas to form a chemical bond with silicon nitride. This produces tiles with exceptional hardness, thermal shock resistance, and resistance to oxidation and corrosion. Unlike traditional refractory bricks, NBSiC tiles maintain structural integrity in rapid temperature changes and aggressive chemical environments.

Key advantages of NBSiC refractory tiles include:

- Superior thermal conductivity for efficient heat transfer

- High mechanical strength that reduces wear and extends service life

- Resistance to thermal shock ideal for kiln setter plates and furnace linings

- Oxidation resistance, preventing degradation in harsh industrial atmospheres

These properties make nitride-bonded SiC tiles a reliable choice for industries requiring durable, efficient, and long-lasting refractory solutions.

Key Features and Technical Advantages of Nitride-Bonded SiC Tiles

Nitride-bonded SiC tiles, also called NBSiC refractory tiles, stand out because of their impressive mix of strength, durability, and resistance. Here’s a quick look at what makes them such a great choice:

- Thermal Resistance: These tiles handle extreme temperatures well, making them perfect for high-temperature furnace linings and kiln setter plates. They resist thermal shock better than many other ceramics, so they don’t crack or break when heating or cooling quickly.

- Mechanical Strength: Thanks to the Si3N4-bonded silicon carbide structure, NBSiC tiles offer excellent mechanical toughness. This means they can withstand heavy loads and impacts inside industrial environments without wearing down fast.

- Chemical Stability: The nitride bonding gives these SiC tiles strong resistance to oxidation and corrosion. This is a big plus in aggressive settings like waste-to-energy boilers or steel blast furnaces where harsh chemicals and gases are common.

- Long Life: Their combined thermal and chemical properties result in longer service life for components like oxidation-resistant SiC batts, aluminum cell sidewall bricks, and blast furnace tuyere refractories.

- Versatility: Because they maintain strength under tough conditions, nitride SiC saggers and other NBSiC refractory tiles fit a broad range of applications that demand reliability.

In short, nitride-bonded SiC tiles deliver robust performance in thermal, mechanical, and chemical areas, making them a reliable choice for demanding US industries.

Versatile Applications in Demanding Industries

Nitride-bonded SiC tiles are built tough for the harshest conditions across several heavy industries. In ceramics kilns, these NBSiC refractory tiles handle extreme heat and thermal cycling without cracking, keeping your operations steady. For waste-to-energy (WTE) boilers, our Si3N4-bonded silicon carbide tiles offer excellent resistance to corrosion and thermal shock, ensuring longer service life in aggressive environments.

In aluminum smelting, NBSiC tiles are used as cell sidewall bricks, standing up to high temperatures and chemical attack. Steel blast furnaces benefit from their durability as tuyere refractories, protecting against erosion and thermal stress. Whether it’s kiln setter plates or oxidation-resistant SiC batts, these nitride SiC saggers offer unmatched performance wherever you need strong, reliable furnace linings.

No matter your industry, our nitride-bonded SiC tiles give you the durability and resistance required in demanding furnace and boiler applications here in the United States.

Gotrays Quality What Sets Our NBSiC Tiles Apart

At Gotrays, quality isn’t just a word—it’s the foundation of every nitride-bonded SiC tile we produce. Our manufacturing process is fine-tuned for consistency and performance, ensuring each tile meets the high standards needed in demanding industrial environments across the US.

Here’s what makes Gotrays NBSiC tiles stand out:

- Precision Manufacturing: We use advanced kiln technologies and strict quality checks to deliver tiles with uniform density and superior strength.

- Customization Options: Whether you need specific sizes, shapes, or grades for your kiln setter plates, waste-to-energy boilers, or blast furnace linings, we tailor each order to fit your unique application.

- T-Clip Integration: For easy installation and secure fit, our tiles come with T-Clip designs that minimize downtime and improve stability during high-temperature operations.

- Durability and Reliability: These tiles consistently resist thermal shock, oxidation, and mechanical wear, extending the life of your furnace linings and reducing maintenance costs.

When you choose Gotrays NBSiC refractory tiles, you’re investing in a product that’s built for the tough demands of US industries like aluminum smelting, steel production, and waste-to-energy plants. Our commitment to excellence means you get reliable performance and service that supports your operation’s success.

Specifications at a Glance

Here’s a quick look at the key specs of our Nitride-Bonded SiC tiles to help you decide if they’re right for your project. You can also download a full datasheet PDF for detailed information.

| Specification | Details |

|---|---|

| Material | Si3N4-Bonded Silicon Carbide (NBSiC) |

| Bulk Density | 2.7 – 3.1 g/cm³ |

| Porosity | 7% – 12% |

| Modulus of Rupture | 20 – 30 MPa |

| Thermal Conductivity | 25 – 30 W/m·K |

| Maximum Service Temperature | Up to 1800°F (980°C) |

| Chemical Resistance | Excellent against oxidation & slag |

| Thermal Shock Resistance | High |

| Installation Type | T-Clip compatible, bondable |

| Common Sizes | Customizable on request |

Download Full Datasheet PDF to get the complete technical details, test results, and installation recommendations. Simply click the button to access the full specs and help your team plan wisely.

Easy Installation and Long-Term Maintenance

Installing Nitride-Bonded SiC Tiles is straightforward when you follow a few key steps. Start by thoroughly cleaning the surface to remove dust, grease, or old adhesive. Use a high-quality refractory bonding agent designed for NBSiC refractory tiles to ensure a strong hold and optimal thermal contact.

Tips for smooth installation:

- Cut tiles carefully to fit your setup without forcing them in place.

- Use T-Clip integration if available, for extra stability and easier replacements.

- Maintain a consistent gap between tiles to allow for thermal expansion.

Once installed, monitoring your kiln setter plates or furnace lining regularly can extend the life of your tiles:

- Inspect for cracks or chips caused by thermal shock.

- Keep an eye out for any signs of chemical wear, especially in aggressive environments like WTE boilers or aluminum smelting cells.

- Schedule routine cleanings to prevent buildup that could affect heat distribution.

For local US users, sourcing bonding materials and replacement tiles is quick and hassle-free. Our support team can guide you on the best bonding products and installation practices tailored to your specific application, ensuring your nitride SiC saggers and other components stay reliable for years.

Frequently Asked Questions About Nitride-Bonded SiC Tiles

What makes Nitride-Bonded SiC tiles better than other refractory options?

Nitride-bonded SiC tiles, or NBSiC refractory tiles, offer exceptional thermal shock resistance, high mechanical strength, and excellent oxidation resistance. This makes them tough in high-temperature furnace linings and ideal for harsh environments like blast furnace tuyere refractories or kiln setter plates.

Can these tiles handle the extreme heat in waste-to-energy boilers?

Yes, NBSiC tiles are designed to withstand very high temperatures and aggressive chemical atmospheres, making them perfect for waste-to-energy tube wall protection and similar applications.

Are Nitride SiC tiles suitable for aluminum smelting and steel industries?

Absolutely. Their high thermal and chemical resistance makes them a top choice for aluminum cell sidewall bricks and steel blast furnace linings.

How do I choose the right size and type of tile for my project?

We recommend contacting our team with specific application details. We offer customization options including T-Clip integration, so your NBSiC tiles fit perfectly and last longer.

What about shipping and delivery across the US?

We ship nationwide with reliable carriers familiar with handling heavy refractory materials. Local customers in the US can expect timely delivery and support for any installation or maintenance questions.

Is there a datasheet or technical guide available?

Yes, an interactive specifications table and full datasheet PDF are available for download. This helps you verify exactly what you’re ordering and plan your installation with confidence.

If you have other questions about Nitride-Bonded SiC tiles or need local shipping info, feel free to reach out anytime. We’re here to help you get the right refractory solution for your high-temperature needs.

Get Your Custom Quote Today

Ready to upgrade your high-temperature furnace linings with top-quality Nitride-Bonded SiC Tiles? Fill out our quick and easy quote form. Just tell us your project dimensions, quantity needed, and application type—whether it’s kiln setter plates, aluminum cell sidewall bricks, or blast furnace tuyere refractories.

We’re here to provide personalized support and competitive pricing tailored to your local needs. Our products come with industry certifications and proven trust signals to give you peace of mind. Get in touch now and take the first step toward durable, thermal shock resistant ceramics designed for the toughest environments.

What we need from you:

- Project dimensions and tile sizes

- Quantity required

- Application details

- Special customization requests

We respond fast and help you get exactly what your operation requires — long-lasting performance with minimal downtime. Request your custom quote today and join businesses across the U.S. relying on Gotrays’ Nitride SiC saggers and more.

Reviews

There are no reviews yet.