Fireclay Brick Hero Section

Explore our premium Fireclay Brick collection built for durability and high performance.

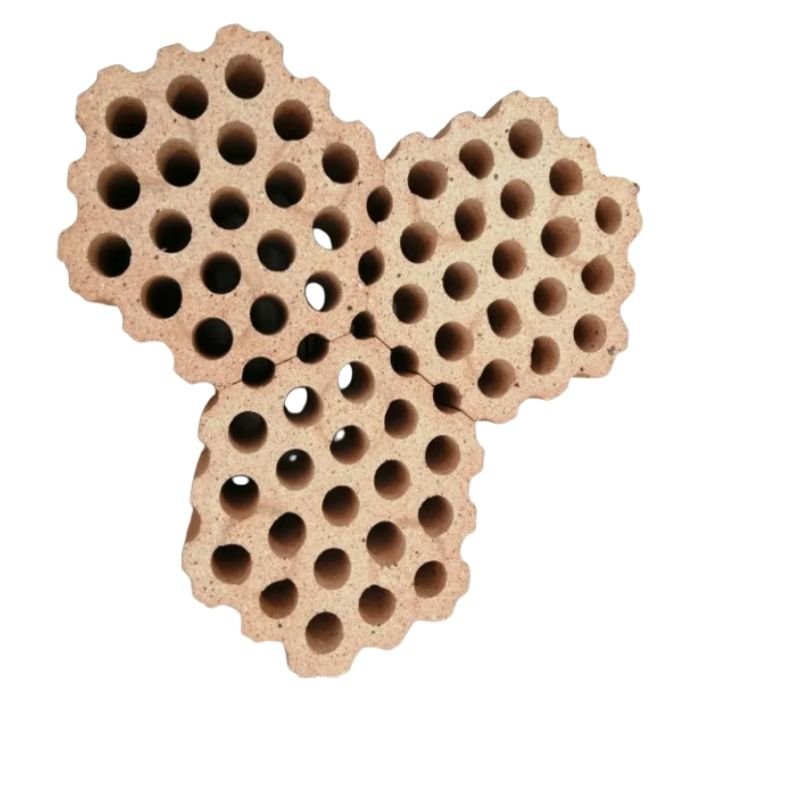

[Image Carousel] See detailed views of fireclay refractory bricks, kiln lining bricks, and fireplace fire bricks in action.

Brand Badge: Trusted by American builders and industrial users for top quality and consistency.

Headline: Fireclay Brick | Heat-Resistant, Durable, and Reliable Refractory Clay Bricks

Key Specs:

- Max temperature up to 2800°F (1538°C)

- Low thermal conductivity for efficient heat retention

- High chemical inertness resistant to slags and corrosion

- ASTM C27 compliant for quality assurance

Call to Action Buttons:

- View Technical Specs

- Request a Sample

- Buy Fireclay Bricks Now

Ready to upgrade your furnace, kiln, fireplace, or pizza oven? Click to explore our full product range!

Product Overview

Fireclay Brick is a reliable choice for any high-heat project. Made from fireclay refractory material, these bricks stand up to intense temperatures while keeping heat where it belongs. They’re perfect for applications like kiln lining bricks, fireplace fire bricks, and pizza oven fireclay bricks.

Key Highlights

- Excellent heat resistance for temperatures up to 2700°F

- Low thermal conductivity reduces heat loss and improves energy efficiency

- Chemically inert to withstand corrosion and slag buildup

- Meets ASTM standards for performance and durability

- Durable and long-lasting under heavy thermal cycling

Whether you’re building a kiln, furnace lining, or repair work, these fire clay refractory bricks deliver consistent performance without breaking down or warping.

Technical Specifications Fireclay Brick

| Specification | Details |

|---|---|

| Composition | High-quality fireclay refractory material with chamotte clay and refractory alumina for durability and heat resistance |

| Max Temperature | Withstands up to 2,300°F (1260°C), ideal for furnace linings and kiln construction |

| Density | Approximately 2.1 g/cm³ for strong but lightweight bricks |

| Porosity | Low porosity (around 18%) reduces thermal conductivity and improves insulation |

| Sizes | Standard sizes include 9 x 4.5 x 2.5 inches, also custom sizes available |

| Colors | Natural fireclay tan with options for red or gray depending on clay source |

| Finishes | Smooth and rough finishes offered to suit different installation needs |

| Eco Options | Sustainable sourcing with options for recycled content materials and low-emission manufacturing processes |

These specs make our fireclay brick a top choice for heat-resistant furnace bricks, pizza oven fireclay bricks, and other heat-intensive applications across the U.S.

Applications and Use Cases

Fireclay bricks are a go-to choice for many high-heat projects across the U.S. Their strong heat resistance and durability make them perfect for:

- Furnace Linings: Provide lasting protection against extreme temperatures in industrial furnaces.

- Kiln Construction: Ideal for building kiln walls that need to withstand constant high heat.

- Fireplace Surrounds: Great for residential fireplaces, offering both safety and a classic look.

- Pizza Ovens: Popular for wood-fired pizza ovens due to their excellent heat retention and thermal stability.

- Boiler Repairs: Used to patch and rebuild boilers, withstanding intense heat and chemical exposure.

Case Study

A Midwest ceramics studio upgraded their kiln linings with fireclay refractory bricks, cutting energy costs by 15% while improving firing consistency — proving these bricks are both practical and cost-effective.

Whether you’re a professional or DIY enthusiast, fireclay bricks deliver reliable performance for heat-intensive projects right here in the U.S.

Benefits and Features of Fireclay Brick

-

Excellent Heat Retention

Fireclay bricks hold heat well, making them ideal for kiln linings, fireplaces, and pizza ovens. This helps maintain consistent temperatures for better results.

-

Energy Savings

Because they retain heat efficiently, these bricks reduce the energy needed to reach and maintain high temperatures, saving on fuel costs over time.

-

Slag and Chemical Resistance

Fireclay refractory material stands strong against slag buildup and chemical wear, extending the life of your furnace or kiln lining.

-

Lightweight Options Available

Some fireclay brick variants are designed to be lighter, making installation easier and reducing structural load, which is great for remodeling projects or upgrades.

-

Sustainable Sourcing

Our fireclay bricks come from responsibly mined clay, supporting environmentally friendly practices without compromising quality.

-

Incorporates Recycled Content

Certain fireclay bricks include recycled materials, helping reduce waste and providing eco-conscious options for green building projects.

These benefits make fireclay bricks a practical choice for both industrial and residential high-temperature applications across the United States.

Installation Guide for Fireclay Brick

Getting your fireclay bricks installed right is key for lasting performance. Here’s a simple step-by-step guide to help you through the process.

Mortar Mixing

- Use a high-quality refractory mortar designed for fireclay bricks.

- Mix according to the manufacturer’s instructions, usually a thick, peanut-butter-like consistency.

- Avoid mixing too wet or dry; the mortar should stick well without sagging.

Laying Pattern

- Lay bricks with a running bond pattern for strong, stable walls.

- Stagger vertical joints by at least half a brick.

- Use a trowel to apply mortar evenly, filling joints completely to avoid gaps.

Curing Tips

- Let the mortar cure slowly by keeping the area moist for 48 to 72 hours after installation.

- Avoid rapid drying or high heat exposure during curing to prevent cracks.

- Once cured, gradually bring the structure up to operating temperature in stages.

Safety Notes

- Wear gloves and safety glasses to avoid irritation from mortar and brick dust.

- Work in a well-ventilated area, especially when mixing mortar.

- Use a dust mask if cutting bricks to protect lungs.

Video Tutorial

We’ve included an easy-to-follow video showing each installation step from mixing mortar to final curing. Check it out for extra guidance.

Following these installation steps ensures your fireclay bricks hold up under high heat and provide lasting protection whether you’re setting up a kiln, furnace, or pizza oven.

Related Products and Accessories

To get the most out of your fireclay brick project, check out our range of related products. We offer refractory mortar designed to withstand high temperatures and create strong, durable bonds. For added strength and heat resistance, consider our high-alumina bricks that complement fireclay refractory material perfectly.

Need extra support inside your kiln or furnace? Our kiln shelves provide reliable heat-resistant surfaces ideal for ceramics and metalwork. For insulation, we carry insulation boards that help keep heat in while protecting surrounding structures.

These accessories are all crafted to meet ASTM standards and made with the U.S. market in mind, ensuring performance and reliability you can count on. Browse our selection and find the right match for your fireclay brick setup.

Customer Reviews and Testimonials

Our Fireclay Brick has earned high praise from both industrial clients and residential users across the United States. With an aggregated rating of 4.8 out of 5 stars, it consistently delivers on performance and durability.

What customers say:

- “These fireclay refractory bricks held up perfectly in my pizza oven. Great heat resistance and easy to work with.” – Sarah M., New Mexico

- “Used for kiln lining in our manufacturing plant. Outstanding thermal stability and long lifespan.” – Mike T., Ohio

- “Excellent firebrick for fireplace surrounds. It looks great and keeps the heat well.” – Jenna K., Vermont

- “The lightweight fire clay refractory made installation easier on our boiler repairs. Definitely recommend.” – Carl D., Texas

Our customers appreciate the consistent quality, energy savings, and the reliable heat retention properties that our fireclay bricks provide. Whether you’re lining a furnace, building a pizza oven, or repairing a fireplace, these bricks deliver solid results every time.

Pricing and Availability

We offer competitive tiered pricing on our fireclay bricks, making it easy to save when you buy in bulk. Whether you need a small batch for a DIY pizza oven or a large order for industrial furnace linings, we’ve got you covered.

Bulk Discounts Available

- Discounts start at orders of 100 bricks or more

- Larger orders get better pricing to help you save more

Stock Status

- Fireclay refractory bricks are regularly stocked at all warehouse locations across the United States

- Fast shipping available for local and national deliveries

Local Pickup Options

- Pick up your bricks directly from our nearest warehouse to avoid shipping fees

- Schedule your pickup online or call ahead to reserve stock

Ready to order? Click the buttons below for instant pricing or to talk with a specialist. We make it easy to get the right fireclay brick for your project, delivered on time and on budget.

Stay Connected and Supported

Sign up for our newsletter to get the latest updates on fireclay brick products, special offers, and expert tips straight to your inbox.

We stand behind every fireclay refractory brick with a solid warranty, so you can trust in quality and durability for your kiln lining bricks, fireplace fire bricks, or pizza oven fireclay bricks.

Need help? Our support team is ready to assist with product info, installation advice, or any questions you have about your fire clay refractory needs.

Subscribe now and stay in the loop on everything fireclay brick.

Contact us anytime for reliable support and peace of mind.

Reviews

There are no reviews yet.