Gotrays Premium Quartz Ceramic Boat

High Purity Fused Quartz Boats for Reliable High Temperature Processing Up to 1200°C

Explore our premium quartz ceramic boats designed for demanding lab and industrial applications. Crafted from 99.99% pure fused quartz (SiO2), these boats deliver exceptional thermal stability and chemical inertness. Ideal for high-temperature semiconductor annealing, chemical vapor deposition (CVD), and diffusion furnace processes, they ensure contamination-free, precise results every time.

Key Highlights

Purity: 99.99% SiO2

Maximum Operating Temperature: 1200°C

Applications: Semiconductor wafer processing, annealing, CVD

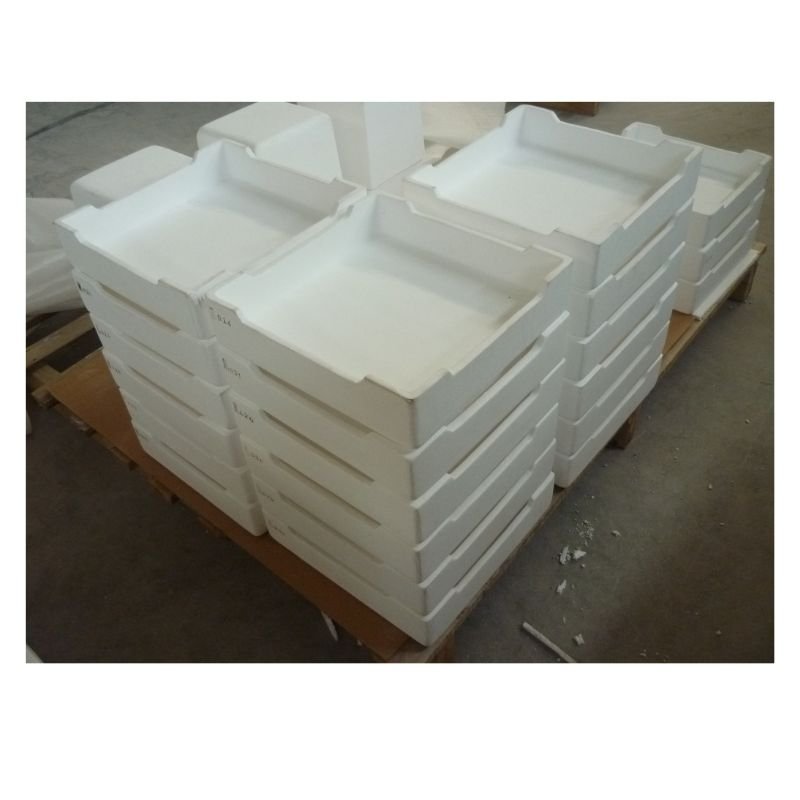

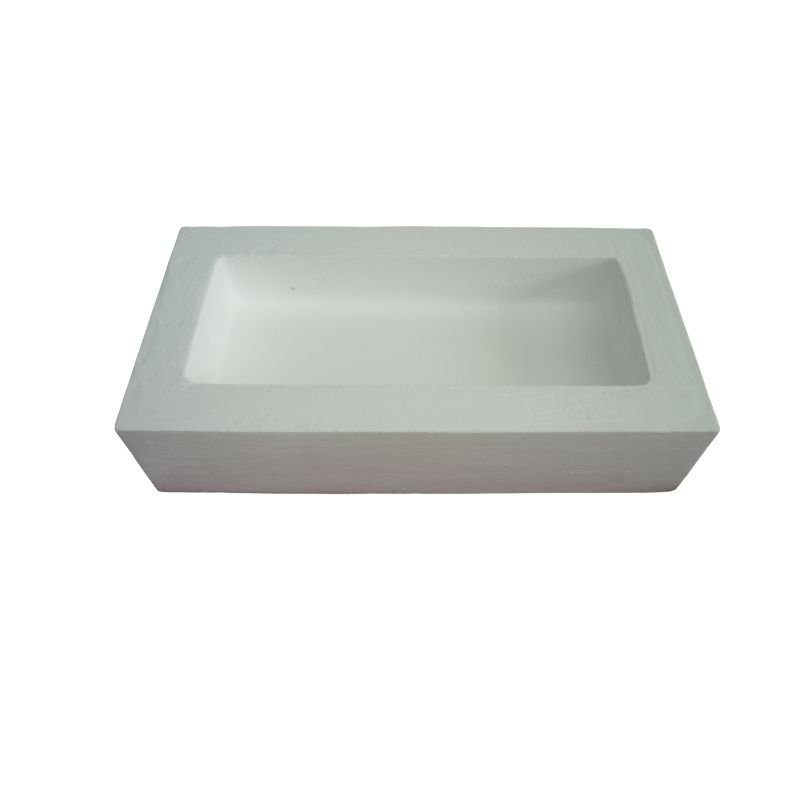

View our high-resolution product image carousel showcasing multiple angles, sizes, and real-world usage scenarios to help you choose the perfect quartz ceramic boat for your needs.

Price and Availability

Request a quote or check availability now. Ready to order? Click Add to Cart or get a Custom Quote tailored to your specifications.

Detailed Product Description

Our Quartz Ceramic Boat is made from high-purity fused quartz, known for its excellent thermal and chemical inertness. This material combines the shape of a traditional boat with the durability of a crucible, making it perfect for high-temperature lab work.

Key features include:

- Thermal shock resistance that handles sudden temperature changes without cracking

- Acid and alkali compatibility ensures it won’t degrade in harsh chemical environments

- Optical transparency allows easy monitoring of your samples during processing

We offer two main variants:

- Standard boats for general use

- Custom slotted boats designed specifically for holding wafers, complete with convenient handles for easy loading and unloading

For best results, handle the boat with care to avoid chipping. Clean it gently using non-abrasive methods, avoiding harsh scrubbing to maintain the surface integrity and optical clarity.

Technical Specifications Table

| Specification | Details |

|---|---|

| Material | High purity fused quartz (99.99% SiO2) |

| Maximum Operating Temp | Up to 1200°C |

| Thermal Shock Resistance | Excellent |

| Chemical Resistance | Acid and alkali resistant |

| Sizes Available | Standard and custom sizes |

| Boat Types | Slotted wafer boat, standard boat with handles |

| Dimensions (example) | Length: 100 – 300 mm, Width: 50 – 150 mm, Height: 30 – 80 mm |

| Weight Range | 50 – 300 grams depending on size |

| Compatibility | Suitable for LPCVD, CVD, annealing, diffusion processes |

| Optical Transparency | Enables visual monitoring during process |

| Load Capacity | Supports multiple wafers or samples according to size |

| Customization | Available on request for specific lab needs |

This table sums up the essential specs of our Gotrays Quartz Ceramic Boat—built for durability and reliability in high-temperature lab setups across the US.

Applications and Use Cases

Gotrays Quartz Ceramic Boats are built to handle a wide range of high-temperature processes in the U.S. lab and manufacturing environments. They’re ideal for:

- Semiconductor wafer processing: perfect for diffusion and oxidation steps in cleanroom settings

- Lab combustion analysis: provides a stable, inert tray for sample firing without contamination

- Photovoltaic material firing: supports solar cell production with precise temperature control

- Metallurgy: holds and manages metal samples during heat treatments

- Sample holding: reliable carriers for various lab tests requiring high purity and thermal resistance

How It Works in Your Setup

In a typical furnace process, the quartz ceramic boat holds your samples or wafers steadily inside the furnace chamber. Its thermal shock resistance and chemical inertness ensure stable results without reacting with your materials.

[Here you would include a simple process flow diagram showing the quartz ceramic boat placed inside a furnace, highlighting its position relative to samples and heat source for clear visual understanding.]

This setup supports smooth workflows in LPCVD, annealing, CVD, and diffusion furnace applications, making it a trusted choice for U.S. labs dealing with high-temperature challenges.

Benefits and Why Choose Gotrays

Gotrays Quartz Ceramic Boats are built to last. You can count on over 1000 use cycles without worrying about wear or contamination. That means reliable, clean results every time, which saves you money compared to constantly replacing disposable alternatives.

Our boats offer:

- Long lifespan for consistent performance

- Contamination-free processing

- Cost savings over single-use products

We’ve been innovating labware since 2005, trusted by more than 500 labs worldwide. When you choose Gotrays, you’re getting proven quality designed specifically for high-temp processes like semiconductor annealing and CVD. Our commitment to durability and purity makes us the go-to choice for labs across the US.

Related Products and Accessories

To complete your lab setup, check out Gotrays Quartz Crucibles, Wafer Holders, and Furnace Tubes. Each item is crafted with the same high purity fused quartz for reliable performance in high-temp processes.

For best results, pair your Gotrays Quartz Ceramic Boat with a Gotrays Quartz Tube. This combo ensures maximum durability and consistent thermal conditions for your CVD, annealing, or diffusion furnace needs.

Explore our accessories to build a full, optimized system designed specifically for semiconductor wafer processing and other high-temp lab work.

Customer Reviews and Testimonials

Our Gotrays Quartz Ceramic Boats have earned a solid 4.8-star rating from over 50 customer reviews. Labs across the U.S. trust our boats for their high-temp processes, especially in semiconductor and CVD applications.

Here’s what a few users are saying:

- “Flawless performance for CVD trials. The thermal shock resistance saved us time and costs.” — MIT Lab Tech

- “Consistent purity and durability, perfect for high-temp wafer annealing.” — Silicon Valley Semiconductor Facility

- “The custom slotted boats with handles made our diffusion furnace runs much easier.” — Phoenix Photovoltaic Research Lab

- “Reliable, contamination-free results every time. Highly recommend for any semiconductor processing.” — Austin Materials Science Lab

These testimonials reflect why labs choose Gotrays every day — proven quality that keeps your processes running smooth and precise.

FAQ Section

What is the difference between quartz and ceramic boats

Quartz boats are made from high purity fused silica (SiO2), offering superior thermal shock resistance and chemical inertness. They handle rapid temperature changes up to 1200°C without cracking. Ceramic boats, while heat resistant, usually have lower purity and can be less durable under thermal cycling. Quartz boats also provide better optical transparency, which helps in monitoring during processes like CVD and annealing.

Can these be customized

Yes, Gotrays quartz ceramic boats can be customized. We offer different sizes, slotted designs for wafers, and handle attachments to fit your specific furnace setup and application needs. Custom orders are available for bulk purchases or unique configurations.

What is the typical shipping lead time

For standard sizes, shipping usually takes 3–7 business days within the US. Custom orders may take a bit longer, typically 1–2 weeks depending on complexity and quantity. We offer reliable tracking and support throughout the delivery process.

Purchase and Support

Ready to buy your Gotrays Quartz Ceramic Boat? Download the detailed spec sheet to review all technical details before ordering. For bulk orders or custom requests, contact our sales team directly— we’re here to help with quotes and personalized service.

We make buying easy and secure with trusted checkout options. Plus, enjoy peace of mind with our 30-day return policy and reliable global shipping across the United States and beyond. Get the high purity fused quartz boat you need with confidence and support every step of the way.

What Are Quartz Ceramic Boats Essential Guide for High Temp Applications

Quartz ceramic boats play a crucial role in high-temperature processes, especially in labs and semiconductor manufacturing. They hold samples, wafers, or chemicals safely inside furnaces, handling extreme heat without breaking down. Understanding the material behind these boats helps you pick the right tool for your high-temp tasks.

Material Breakdown Fused Quartz vs Traditional Ceramics

-

Fused Quartz

Made from pure silicon dioxide (SiO2), fused quartz is processed at very high temperatures to form a glassy, uniform material. It’s prized for its exceptional thermal shock resistance and high purity (99.99% SiO2). This means it can handle sudden temperature changes without cracking and stays chemically stable during reactions.

-

Traditional Ceramics

Usually made from alumina, silicon carbide, or other metal oxides, ceramics are tough and heat resistant but less pure than fused quartz. They tend to have lower optical clarity and can sometimes react with certain chemicals at high temps. Ceramics handle mechanical stress well but may not match the chemical inertness of fused quartz.

Key Properties

-

Thermal Stability

Quartz ceramic boats safely tolerate temperatures up to 1200°C, making them ideal for processes like CVD, annealing, and diffusion.

-

Chemical Inertness

They resist acids, alkalis, and most reactive gases, which helps avoid contamination during sensitive experiments or manufacturing steps.

-

Purity Standards

Gotrays Quartz Ceramic Boats meet the highest purity levels (99.99% SiO2), ensuring clean, reliable results with minimal risk of trace contamination.

These qualities make quartz ceramic boats a smart choice for labs and industries needing consistent, high-performance tools for demanding thermal applications.

Why Choose Gotrays Quartz Ceramic Boats for Your Lab Needs

Gotrays quartz ceramic boats stand out for their superior thermal shock resistance, handling rapid temperature changes without cracking. This means fewer replacements and steady performance in demanding high-temp environments. Plus, they offer excellent contamination control, thanks to their high purity fused quartz construction—helping you keep processes clean and reliable.

These boats have proven themselves across semiconductor manufacturing, photovoltaics, and metallurgy. Whether you’re running annealing, CVD, or diffusion processes, Gotrays boats deliver consistent results that labs in the U.S. trust.

On top of performance, Gotrays backs every quartz ceramic boat with ISO-certified manufacturing and thorough testing. That quality assurance assures you’re getting labware that meets strict industry standards, built to last and perform with precision.

Technical Specifications and Customization Options

Our Gotrays Quartz Ceramic Boats come in a range of standard sizes designed to fit most diffusion furnaces and CVD setups. Each boat is crafted from high purity fused quartz with a guaranteed purity of 99.99% SiO2, ensuring superior thermal and chemical performance.

Standard Sizes and Capacities

| Model | Dimensions (L x W x H) | Max Load Capacity | Max Operating Temp |

|---|---|---|---|

| Small | 150 x 50 x 25 mm | Up to 10 wafers | 1200°C |

| Medium | 200 x 75 x 35 mm | Up to 20 wafers | 1200°C |

| Large | 300 x 100 x 40 mm | Up to 30 wafers | 1200°C |

These sizes cover most semiconductor wafer carriers and lab annealing boat needs, providing versatility across applications including diffusion, oxidation, and CVD processes.

Custom Configurations Available

To meet specific lab requirements, we offer custom quartz wafer boats including:

- Slotted Designs for better wafer separation and airflow

- Handle Attachments for safer handling and easier transport

- Bulk Order Options with volume discounts for consistent lab supply

All custom boats maintain the premium quality and thermal shock resistance our customers expect. Contact us for quotes and specifications to fit your exact furnace and process setup.

How to Use Gotrays Quartz Ceramic Boats in Furnace Setups

Getting the most out of your Gotrays quartz ceramic boat is simple when you follow the right steps. Whether you’re working with LPCVD, diffusion, or annealing processes, proper handling and cleaning ensure reliable, long-lasting performance.

Step by Step Handling Tips

- Wear clean gloves to avoid contamination when handling the boat.

- Place the boat carefully inside the furnace, making sure it sits flat and stable.

- Load wafers or samples gently to prevent chipping or cracking.

- Avoid sudden temperature changes that can cause thermal shock.

Cleaning Protocols

- After use, let the boat cool completely before cleaning.

- Use mild detergents with warm water to wash off residues.

- Avoid harsh abrasives or metal brushes that can scratch the surface.

- Rinse thoroughly and dry fully to prevent moisture damage.

- Inspect for damage before next use to ensure safety and quality.

Compatibility with Furnace Processes

Gotrays quartz ceramic boats are designed to work seamlessly with:

- LPCVD (Low Pressure Chemical Vapor Deposition) processes where purity and thermal stability matter.

- Diffusion furnaces for uniform high-temperature treatments.

- Annealing steps requiring controlled environments up to 1200°C.

This makes our quartz combustion tray a versatile, reliable choice for most semiconductor, photovoltaic, and lab annealing applications.

Following these simple steps helps you maximize the lifespan and performance of your Gotrays quartz ceramic boat in any high-temp furnace setup.

Frequently Asked Questions About Quartz Ceramic Boats

What’s the difference between quartz ceramic boats and alumina or silicon carbide boats?

Quartz ceramic boats are made from high purity fused quartz (SiO2), known for excellent thermal shock resistance and chemical inertness, especially up to 1200°C. Alumina boats can handle higher temperatures but are less transparent and can be more brittle. Silicon carbide boats are very tough and high-temp resistant but may introduce contamination risks in ultra-pure semiconductor processing. Quartz boats offer the best balance for clean, stable high-temp processing.

What is the maximum temperature quartz ceramic boats can handle?

Gotrays’ quartz ceramic boats can safely endure temperatures up to 1200°C. Beyond this, quartz may soften or degrade. They are ideal for applications like semiconductor annealing, CVD, and oxidation processes within this range.

Can these boats resist chemicals?

Yes, quartz ceramic boats have excellent resistance to acids and alkalis, making them suitable for most lab and industrial chemical environments without risk of contamination or corrosion.

How long does shipping take in the US and EU?

Orders to the US typically arrive within 5-7 business days. EU shipments take around 7-10 business days due to customs and logistics. Expedited shipping is available on request.

What warranty and after-sales support do you offer?

Gotrays provides a 12-month warranty covering manufacturing defects. Our customer support team is available for technical help, product advice, and returns. We also offer replacement options if your product arrives damaged.

Do you offer bulk pricing and custom orders?

Yes, bulk orders and custom quartz wafer boats are available. Contact our sales team to discuss volume discounts, special sizes, or specific design needs tailored to your lab’s processes.

Related Gotrays Products for Complete Labware Solutions

For a smooth and efficient workflow, pair your Gotrays Quartz Ceramic Boat with our range of matching labware. Our high purity quartz crucibles and durable quartz tubes are designed to complement your setup perfectly. These products provide consistent thermal performance and chemical resistance, helping you get reliable results every time.

Using Gotrays quartz crucibles alongside your boat makes sample handling easy and contamination-free. Meanwhile, our quartz tubes fit seamlessly in diffusion and CVD furnace systems, completing your high-temp processing line.

Explore these trusted accessories to build a full labware system that meets your semiconductor, photovoltaic, or metallurgy process needs. When you choose Gotrays, you’re gearing up with proven, premium quartz solutions built for the US market’s demanding lab environments.

Customer Success Stories and Reviews

Our quartz ceramic boats have earned high praise from semiconductor professionals across the U.S. Here’s what real users are saying:

- “Flawless performance during CVD processes. The purity and thermal stability of Gotrays boats helped us achieve consistent, contamination-free results.” – Lab Tech, MIT

- “These quartz wafer carriers hold up to repeated annealing cycles without cracking. Reliable and easy to clean, perfect for our diffusion furnace setups.” – Process Engineer, California

- “Great value compared to disposable alternatives. The thermal shock resistance and chemical inertness make this boat ideal for high-temp applications in photovoltaics.” – Materials Scientist, Arizona

- Aggregate Rating: 4.8 stars from over 50 reviews

Our customers appreciate how Gotrays quartz ceramic boats save time and reduce lab costs, all while delivering top-notch results. Whether for semiconductor wafer processing, CVD trials, or metallurgical sample holding, these boats get the job done.

Ready to Order

Getting your Gotrays Quartz Ceramic Boat is simple and fast. Whether you need a standard fused quartz boat for semiconductor wafer processing or a custom quartz wafer boat tailored to your lab’s specs, we’ve got you covered.

- Request a quote for custom sizes or bulk orders

- Add to Cart for quick purchase of standard models

- Download the spec sheet to review detailed dimensions and material info

- Contact our sales team for support with bulk pricing and special requests

We ship across the US with secure checkout, fast delivery, and a 30-day return policy. Trust Gotrays for reliable high-temperature quartz ceramic trays made to last in your lab.

Reviews

There are no reviews yet.