Why Choose Gotrays Alumina Ceramic Discs

Gotrays Alumina Ceramic Discs deliver unmatched performance for demanding industrial applications where reliability and precision matter. Our discs are crafted from high-purity Al2O3, offering exceptional wear resistance, thermal stability, and electrical insulation. This ensures long-lasting durability even in extreme environments, making them ideal for various sectors including aerospace, electronics, and chemical processing.

Core Value Proposition

Gotrays focuses on providing highly engineered alumina oxide discs that combine superior material quality with precise manufacturing technology. Our ceramic substrate plates are designed to meet exact specifications, ensuring consistent performance and minimal failure rates. By leveraging advanced production methods, Gotrays guarantees fast turnaround times without compromising material integrity or mechanical strength.

Key Differentiators

- Premium Material Purity: Our discs feature a minimum alumina content of 99.6%, reducing impurities that could affect performance.

- Precision Machining: Custom alumina ceramic substrates are machined to tight tolerances, supporting seamless integration into complex assemblies.

- Wear and Corrosion Resistance: The high hardness and chemical stability of our discs protect critical components from degradation.

- Thermal Shock Resilience: Our alumina oxide discs endure rapid temperature changes without cracking, outperforming typical ceramic alternatives.

- Customization Flexibility: From standard sizes to bespoke specifications including ZTA toughened alumina discs, Gotrays adapts to your exact needs.

Choosing Gotrays means partnering with a trusted supplier who prioritizes material excellence and application-specific solutions tailored for industrial success.

Technical Specifications and Material Properties

Our Gotrays Alumina Ceramic Discs are made from high-purity Al2O3, also known as alumina oxide. This material gives the discs excellent hardness and strength, making them ideal as industrial ceramic insulator discs or ceramic substrate plates. They offer superior wear resistance and are highly stable in harsh environments.

Here’s what you can expect in terms of key specs and material properties:

- Purity: 99.5%+ alumina oxide (Al2O3)

- Density: Approximately 3.9 g/cm³

- Hardness: Mohs scale 9 (harder than most metals)

- Flexural Strength: Up to 450 MPa

- Thermal Conductivity: Around 25 W/m·K

- Dielectric Strength: 10-20 kV/mm

- Operating Temperature: -40°C to 1600°C

- Thermal Shock Resistance: Excellent, suitable for rapid temperature changes

- Wear Resistance: Outstanding, ideal for valve cartridges and seal applications

Interactive Specs Table

| Property | Value | Benefits |

|---|---|---|

| Purity | 99.5%+ Al2O3 | High chemical stability |

| Density | ~3.9 g/cm³ | Lightweight but strong |

| Hardness | Mohs 9 | Extreme wear resistance |

| Flexural Strength | Up to 450 MPa | Durable under pressure |

| Thermal Conductivity | 25 W/m·K | Efficient heat dissipation |

| Dielectric Strength | 10-20 kV/mm | Excellent electrical insulation |

| Operating Temperature | -40°C to 1600°C | Wide range for tough environments |

| Thermal Shock Resistance | High | Resists cracking under heat stress |

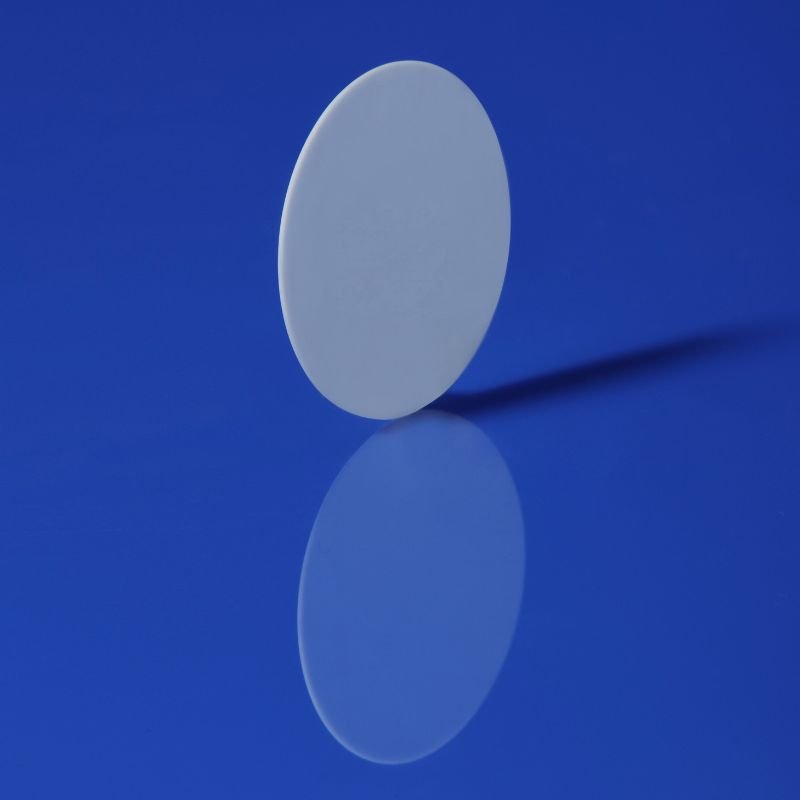

Visual Aid

[Insert image or diagram here showing a cross-section of the alumina ceramic disc highlighting layers, microstructure, or dimensions for better understanding]

This robust set of specifications makes the Gotrays alumina ceramic disc a versatile choice across industries, whether you need a precision machined alumina round or a wear-resistant alumina seal.

Exceptional Features and Benefits

Gotrays Alumina Ceramic Discs stand out because of their reliable performance in tough environments. Here’s what you can expect:

Superior Wear and Corrosion Resistance

Our alumina oxide discs handle abrasive conditions without breaking down. They resist chemical corrosion, making them perfect for industrial ceramic insulator disc uses where durability is key.

Thermal Shock Resilience

These ceramic discs tolerate sudden temperature changes. Whether it’s a high-purity Al2O3 wafer in electronics or a thermal shock resistant ceramic disc in aerospace, you know your parts won’t crack under pressure.

Electrical Insulation Excellence

Alumina’s natural electrical insulation makes our ceramic substrate plates ideal when you need to cut electrical flow. This is essential for semiconductor and mechanical engineering applications.

Lightweight Yet Robust

You get a precision machined alumina round that’s strong but not heavy. This balance is key for aerospace parts and medical devices where weight matters but strength can’t be sacrificed.

Custom Machinability

Need a custom alumina ceramic substrate shaped just right? Our discs are designed to be easily machined to fit unique specifications, from wear-resistant alumina seals to engineering alumina valve cartridges.

These features combine to make Gotrays alumina ceramic discs a trusted choice for a range of industries.

Versatile Applications Across Industries

Our Gotrays Alumina Ceramic Discs are built to meet the demands of many industries thanks to their durability and precision. Here’s where they fit best:

Electronics and Semiconductors

Used as ceramic substrate plates and high-purity Al2O3 wafers, these discs offer excellent electrical insulation and thermal stability for sensitive electronics and semiconductor manufacturing.

Aerospace and Defense

The thermal shock resistant ceramic disc and wear-resistant alumina seal make them ideal for harsh aerospace environments, offering toughness and reliability in high-stress applications.

Chemical Processing

Their superior corrosion resistance keeps these discs working in aggressive chemical environments, making them perfect for industrial ceramic insulator discs and valve cartridges.

Mechanical Engineering

Precision machined alumina rounds and ZTA toughened alumina discs are favored in mechanical parts that need strength, wear resistance, and dimensional stability.

Medical and Lab

Custom alumina ceramic substrates are widely used in medical devices and laboratory equipment, where purity and performance are critical.

User Habit Tie-In

We know many U.S. customers rely on quick, reliable solutions that fit their specific application needs. That’s why our alumina discs are ready to serve from one-off prototypes to large-scale production runs, streamlining workflow and reducing downtime.

Customization Options with Gotrays

Tailored Solutions

At Gotrays, we understand that every project has its own needs. That’s why our alumina ceramic discs can be customized to fit your exact requirements. Whether you need a specific size, thickness, or grade of alumina oxide disc, we work closely with you to deliver the right ceramic substrate plate that meets your technical and budget needs.

Options List

Here’s a quick look at what you can customize with us:

- Size and shape: From precision machined alumina rounds to custom wafer dimensions

- Material grade: Choose from high-purity Al2O3 wafers to ZTA toughened alumina discs

- Surface finish: Smooth or textured for better adhesion or sealing

- Thickness: Thin ceramic substrates for lightweight applications or thicker wear-resistant alumina seals

- Additional machining: Holes, slots, or other features tailored for your design

Process Flowchart

Our customization process is simple and transparent:

- Consultation: Share your project specs and challenges

- Design Review: We propose solutions and customization options

- Prototyping: Get samples or prototypes for testing

- Production: Precision machining and finishing of your custom alumina ceramic substrate

- Quality Check: Rigorous inspection to ensure specs and performance

- Delivery: Fast shipping tailored to your timeline

With Gotrays, you get full control with expert support for bespoke ceramic discs designed to perform exactly as you need.

Quality Assurance and Certifications

At Gotrays, quality is not just a promise—it’s a guarantee. Every alumina ceramic disc undergoes rigorous testing protocols to make sure it meets the highest standards. From checking purity levels of the alumina oxide disc to precision measurements on our ceramic substrate plates, we leave nothing to chance. Our testing covers wear resistance, thermal shock resilience, electrical insulation, and mechanical strength to ensure you get reliable products every time.

We hold certifications that confirm our commitment to quality and industry standards. Our alumina ceramic discs comply with ISO 9001 quality management systems and are tested to meet ASTM standards for high-purity Al2O3 wafers and industrial ceramic insulator discs. These certifications mean you can trust Gotrays products for demanding applications—from aerospace parts to medical components.

We also care about the planet. Our manufacturing process emphasizes sustainability by reducing waste and using eco-friendly materials wherever possible. When you choose Gotrays, you’re not only getting a top-tier alumina ceramic disc—you’re supporting responsible production that benefits your business and the environment.

Pricing Shipping and Easy Ordering

Transparent Pricing

At Gotrays, we keep our pricing straightforward and competitive. You’ll know exactly what you’re paying for with our clear quotes—no hidden fees or surprise charges. Whether you need a small batch of alumina ceramic discs or a large industrial order, we offer fair rates tailored to your needs.

Global Logistics

We ship fast and securely across the United States and worldwide. Our reliable logistics partners ensure your alumina oxide discs and ceramic substrate plates arrive on time and in perfect condition. Tracking is easy, so you stay updated every step of the way.

Easy Ordering

Ordering from Gotrays is simple. Just pick your specifications for your custom alumina ceramic substrate or standard size and place your order online or over the phone. Need help? Our team is ready to guide you through the process, ensuring you get exactly what you need without hassle.

Get your precision machined alumina round today – Request a quote or contact us now!

Frequently Asked Questions FAQs

What is an Alumina Ceramic Disc used for?

Alumina ceramic discs are versatile components used for electrical insulation, wear-resistant seals, and high-strength substrates in industries like aerospace, electronics, and chemical processing.

How does Gotrays Alumina Ceramic Disc stand out?

Our discs offer superior wear and corrosion resistance, excellent thermal shock resilience, and precise machining, making them reliable and customizable for your specific needs.

Can I customize the size or shape of the alumina oxide disc?

Yes, Gotrays provides tailored solutions including custom alumina ceramic substrates and precision machined parts to fit your exact specifications.

Is the alumina ceramic disc good for high-temperature environments?

Absolutely. Our thermal shock resistant ceramic discs maintain performance under extreme temperature changes, ideal for demanding industrial conditions.

What material purity do Gotrays alumina ceramic discs have?

We use high-purity Al2O3 wafers ensuring consistent quality and reliability across all batches.

Are these ceramic discs lightweight?

Yes, despite being robust and tough, our alumina oxide discs are lightweight, enhancing ease of handling and integration.

Do you offer certification and quality assurance?

All Gotrays alumina ceramic discs undergo rigorous testing and come with certifications verifying their material quality and performance reliability.

How quickly can I get my order shipped?

We offer transparent pricing with fast, reliable shipping across the United States and worldwide, ensuring you get your alumina ceramic disc when you need it.

If you have more questions or need custom options, our customer support is ready to help.

Related Gotrays Products

At Gotrays, we offer a range of high-quality ceramic components designed to complement our alumina ceramic discs. Check out these related products that fit perfectly with your needs:

- Alumina Oxide Plates – Ideal for use as ceramic substrate plates in various industrial applications.

- Custom Alumina Ceramic Substrates – Precision-machined for electronics and semiconductor industries.

- ZTA Toughened Alumina Discs – Engineered for extra strength and durability in harsh environments.

- Engineering Alumina Valve Cartridges – Perfect for mechanical and chemical processing systems.

- Thermal Shock Resistant Ceramic Insulator Discs – Designed to deliver excellent thermal insulation.

- Wear-Resistant Alumina Seals – Built to last in abrasive and corrosive settings.

All these products maintain the same high standards of wear resistance, thermal shock resilience, and precision machining you expect from Gotrays. Explore them to find the right match for your project or industry requirements.

Reviews

There are no reviews yet.